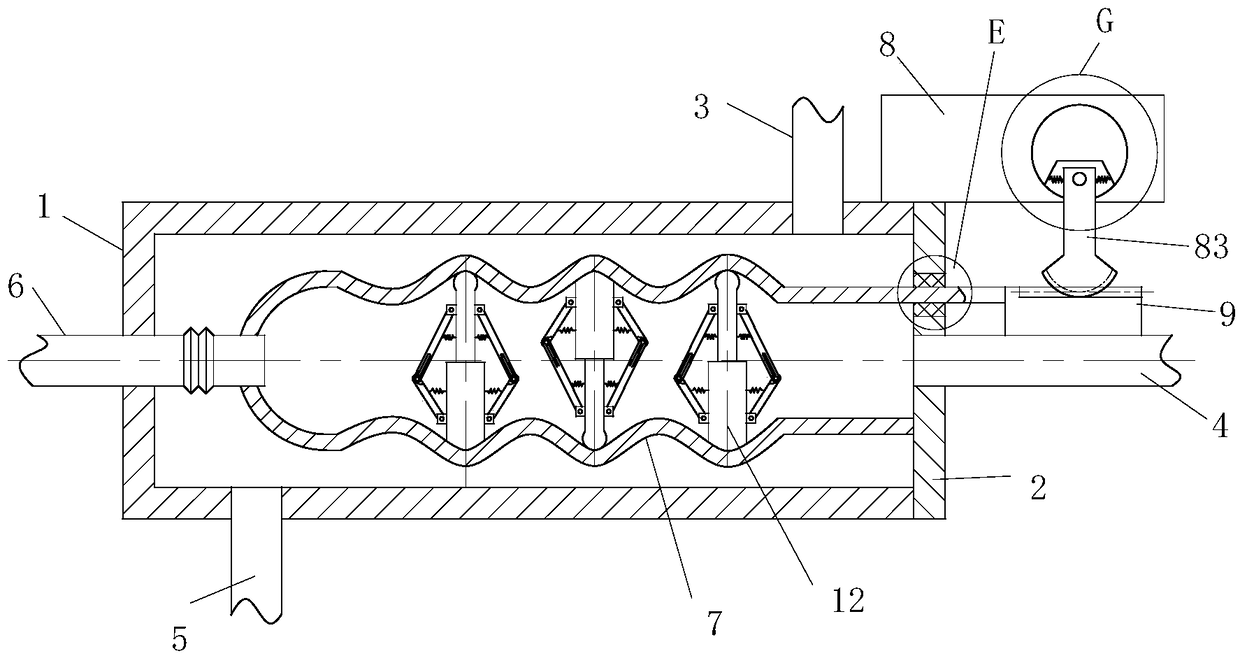

Heat exchanger

A heat exchanger and hot water technology, applied in heat exchange equipment, heat exchanger types, indirect heat exchangers, etc., can solve problems such as low heat transfer coefficient, restricted heat exchange efficiency, and insufficient fluid flow, etc., to achieve Improve heat transfer efficiency, reduce impact damage, and increase service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

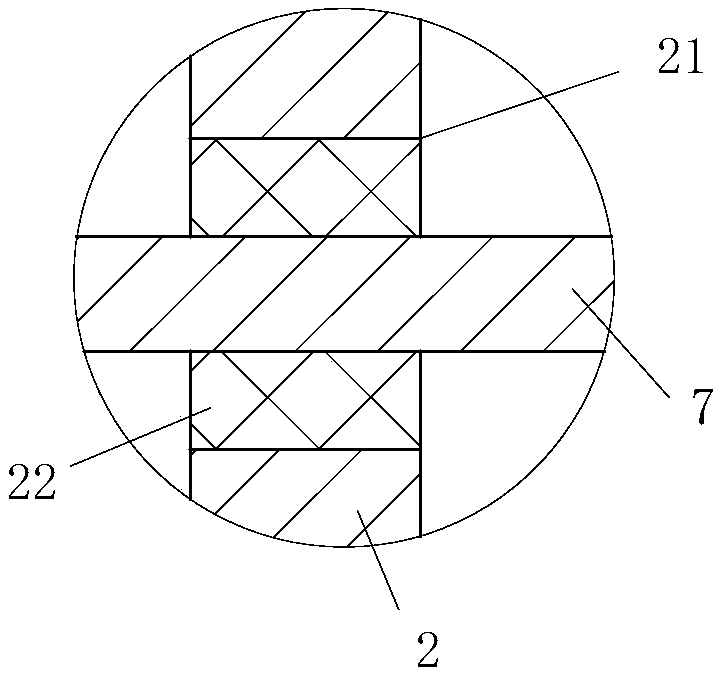

Embodiment approach

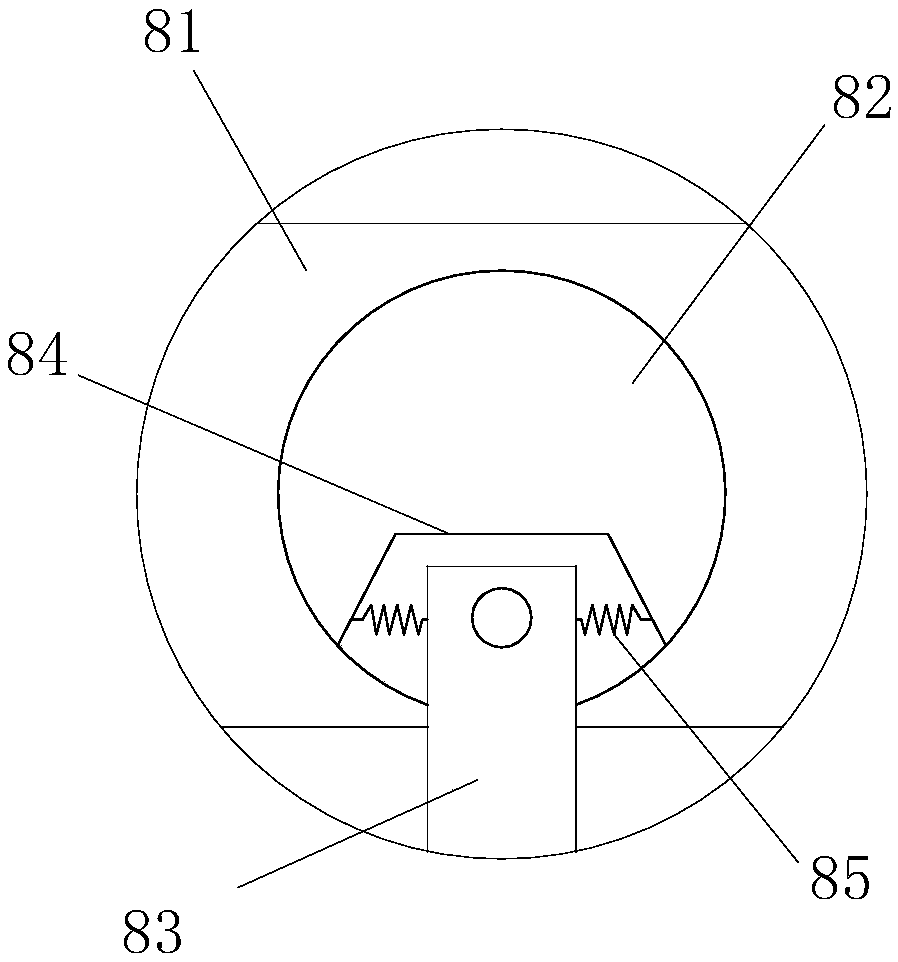

[0029]As an embodiment of the present invention, the rotating module 8 includes a motor 81, a rotating plate 82, and a gear rod 83. The motor 81 is fixedly installed on the housing 1, and the rotating plate 82 is fixedly connected to the output shaft of the motor 81. , a fan-shaped groove 84 is set on the rotating plate 82, and the gear rod 83 is fixedly installed in the fan-shaped groove 84. A buffer spring 85 is used to support the two sides of the gear rod 83 and the fan-shaped groove 84. During work, the rotating plate 82 drives the gear rod 83 to mesh with the rack 9 intermittently, so that the rack 9 slides back and forth, and utilizes the buffer spring 85 between the two sides of the gear rod 83 and the rotating plate 82 to make the gear rod 83 contact with the rack 9 instantly. The impact machine is relieved, reducing the impact damage of the gear rod 83 and increasing the service life.

[0030] As an embodiment of the present invention, two first arc-shaped shrapnels ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com