Electrolysis polishing method for preparing pure titanium and titanium alloy EBSD (electron back-scattered diffraction) sample

An electrolytic polishing and titanium alloy technology, applied in the field of metal material processing, can solve the problems of complicated operation and high cost, and achieve the effects of improving sample quality, good light transmittance, and avoiding electrolyte corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

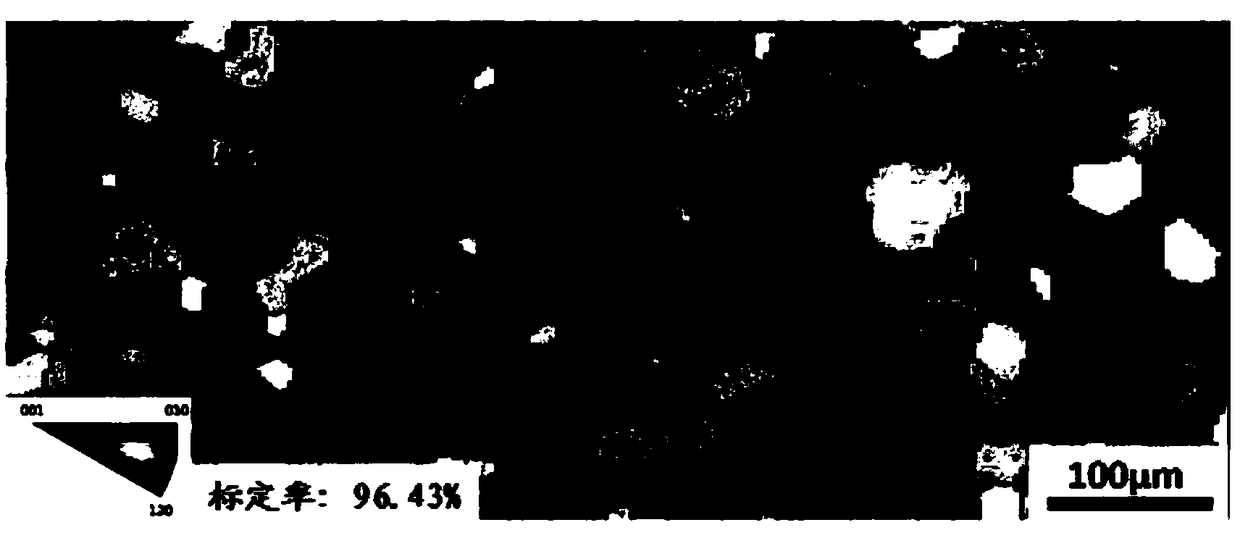

[0028] Example 1:

[0029] Use wire cutting technology to take a pure titanium flake with a thickness of 0.5mm from the pure titanium sample to be tested, and grind the two sides of the pure titanium flake with 280# and 400# silicon carbide dry sandpaper until its thickness is reduced to 0.28mm. , Grind the side of the obtained pure titanium flakes with 400# silicon carbide dry sandpaper and then use 600#, 800#, 1000# and 1200# silicon carbide dry sandpaper to grind and control its thickness to 0.12mm. Take 3 samples of length x width 5 x 5mm from the obtained pure titanium flakes, grind the burrs of the samples smoothly with 1200# silicon carbide dry sandpaper, and place the pure titanium samples taken out in the sample of the magnetodynamic double jet thinner In the clip, the smoother side of the pure titanium sample is placed on the conductive metal sheet in the sample holder and shields the double nozzle holes on the conductive metal sheet, and a transparent, flexible, acid-c...

Example Embodiment

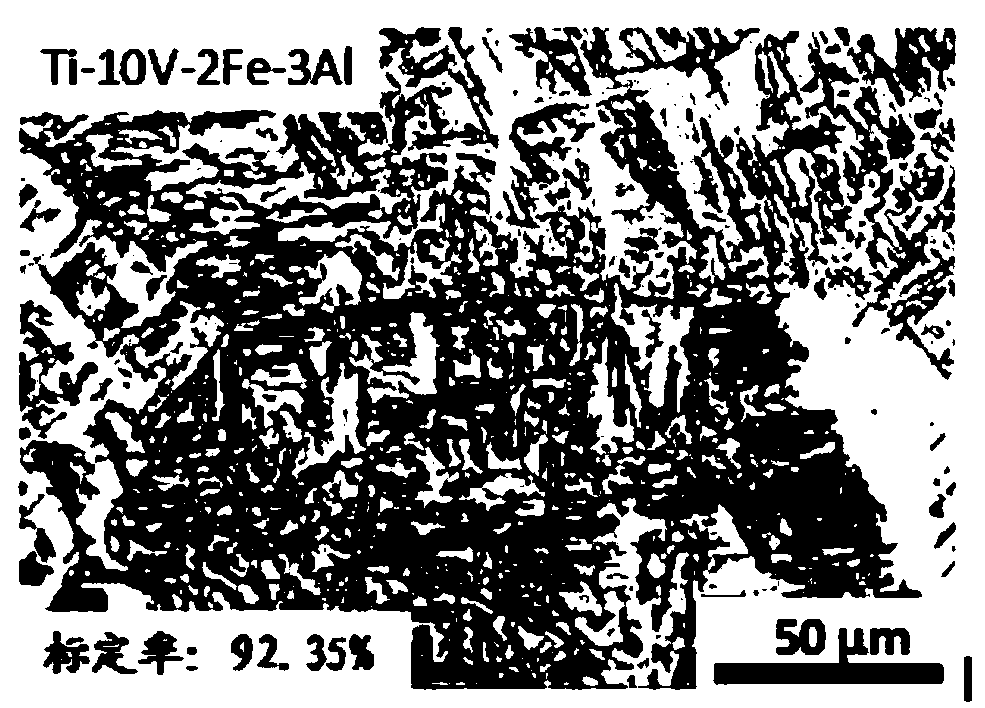

[0030] Example 2:

[0031] Use wire-cutting technology to take Ti-10V-2Fe-3Al flakes with a thickness of 1mm from the Ti-10V-2Fe-3Al sample to be tested, and use 280# and 400# silicon carbide dry sandpaper to test Ti-10V-2Fe. Grind both sides of the -3Al sheet until its thickness is reduced to 0.25mm. The side of the obtained Ti-10V-2Fe-3Al sheet that has been ground with 400# silicon carbide dry sandpaper is then sequentially used 600#, 800#, 1000# and 1200 #Silicon carbide dry sandpaper to grind and control its thickness to 0.14mm, and then from the Ti-10V-2Fe-3Al flakes obtained after grinding, take 5 samples of length × width 4×5mm, and use 1200# silicon carbide dry sandpaper Grind the burrs of the sample smoothly, and place the removed Ti-10V-2Fe-3Al sample in the sample holder of the magnetodynamic double-jet thinner, where the smoother side of the Ti-10V-2Fe-3Al sample is attached to the sample The conductive metal sheet in the clip is placed and shields the double nozzle...

Example Embodiment

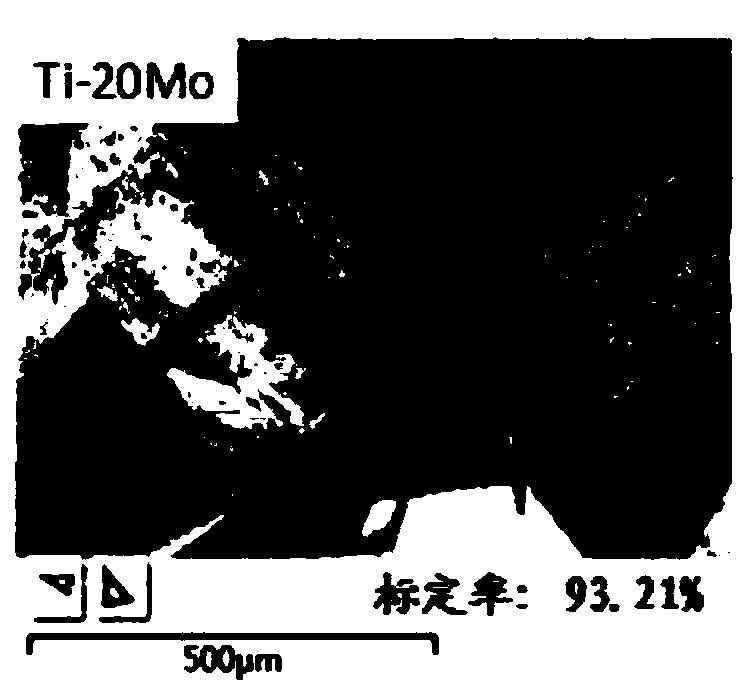

[0032] Example 3:

[0033] Use wire cutting technology to take Ti-20Mo flakes with a thickness of 0.8mm from the Ti-20Mo sample that needs to be observed, and use 280# and 400# silicon carbide dry sandpaper to grind the two sides of the Ti-20Mo flakes until the thickness is reduced. The thickness of the Ti-20Mo flake that has been ground with 400# silicon carbide dry sandpaper is then ground with 600#, 800#, 1000# and 1200# silicon carbide dry sandpaper in turn and the thickness is controlled to 0.1mm. Then take 4 samples of length x width 4 x 4mm from the Ti-20Mo flakes obtained after grinding, grind the burrs of the samples smoothly with 1200# silicon carbide dry sandpaper, and place the taken Ti-20Mo sample on the magnetic double In the sample holder of the spray thinner, the smoother side of the Ti-20Mo sample is placed on the conductive metal sheet in the sample holder and covers the double nozzle holes on the conductive metal sheet, and the thickness is 0.3mm. The acid cor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com