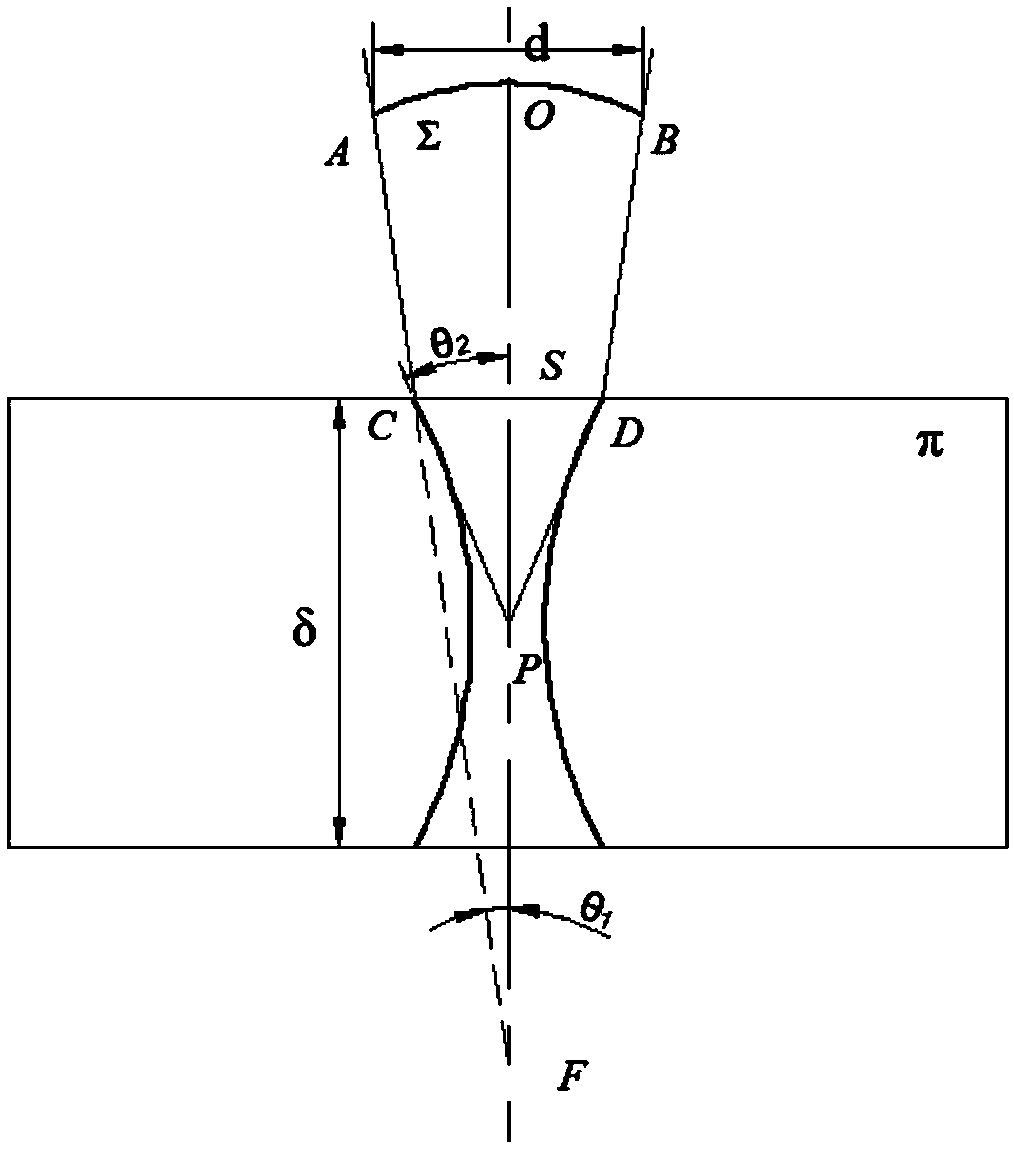

Water immersion ultrasonic flaw detection method for rolled steel defects

An ultrasonic and water immersion technology, used in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, and material analysis, etc. The effect is not very ideal, etc., to achieve the effect of enhancing the scanning signal and accurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

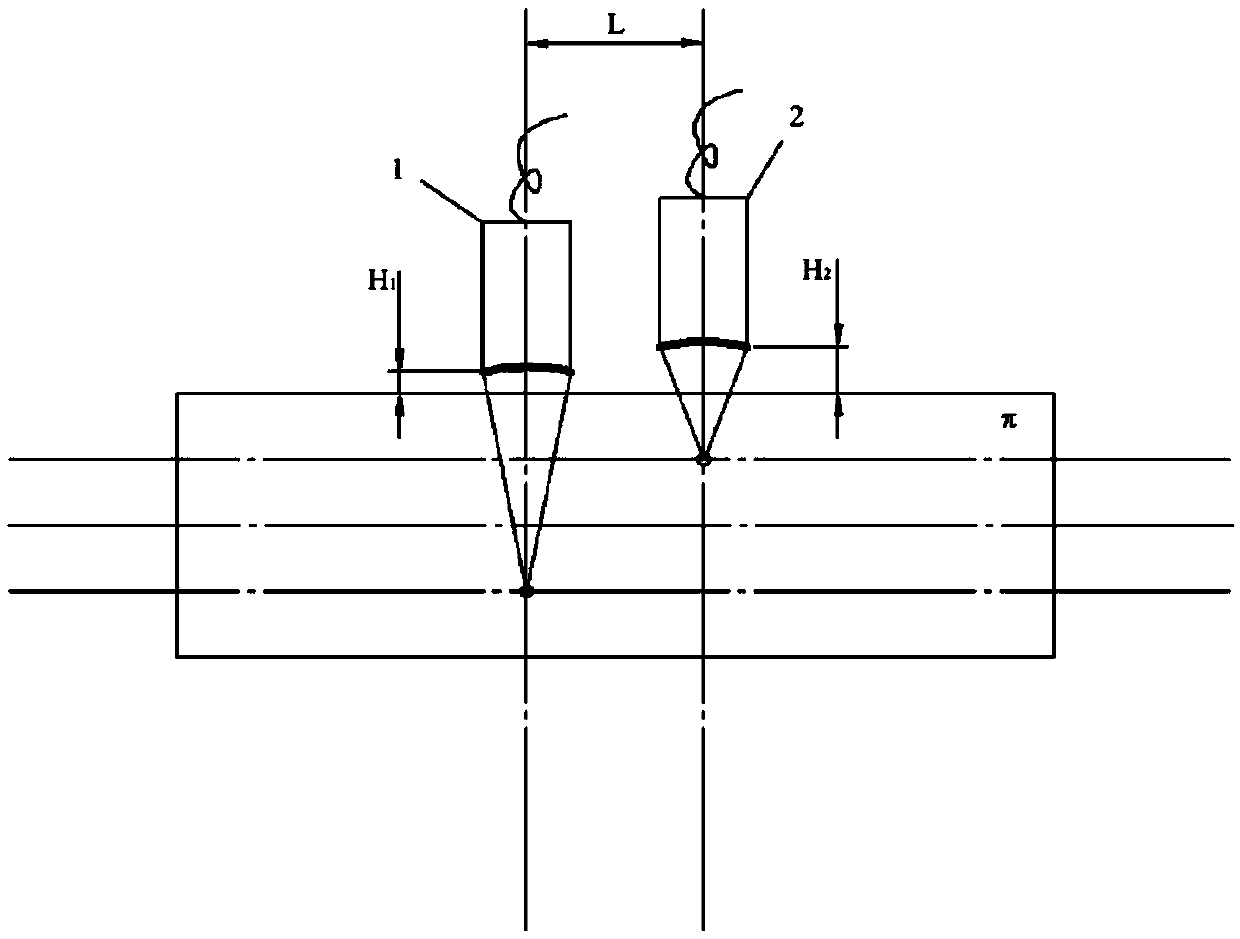

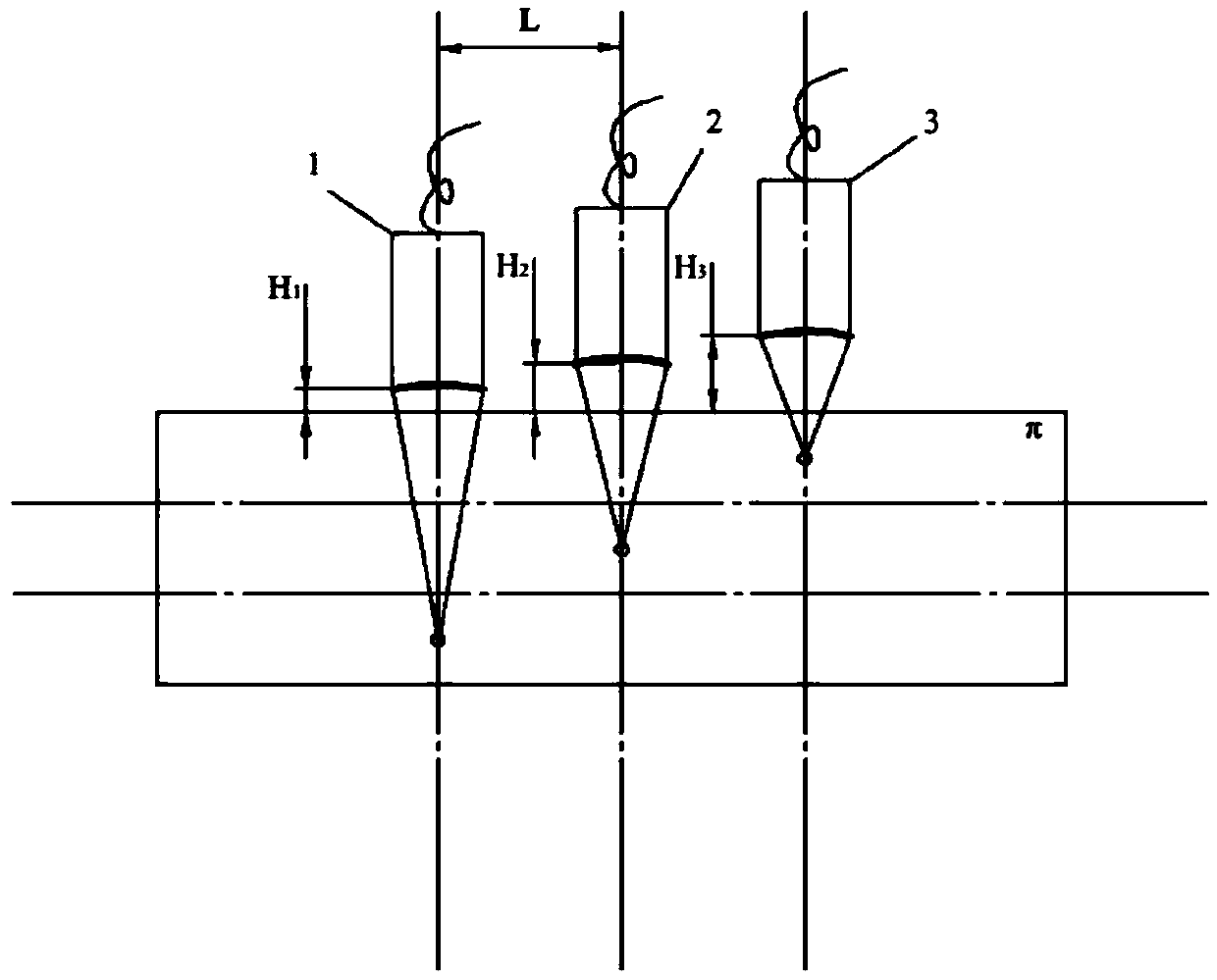

Method used

Image

Examples

Embodiment Construction

[0040] A company produced a Q235 rolled steel plate with a thickness of 25mm. Through online inspection, it was found that there was a defect in a certain section of the steel plate, and the depth of the defect was at 18mm. Now cut the defect into a sample of 100×100×25mm, use the experimental device in this invention to test the sample, and compare the results with the traditional single-probe water immersion testing method. The test results of the two methods are as follows:

[0041]Through single-focus probe water immersion detection, the water layer distance is generally adjusted to about a quarter of the workpiece thickness. Here, a water immersion focus probe with a focal length of 80mm in water, a frequency of 5MHz, and a chip diameter of 14mm is used. The thickness of the water layer is set to 7mm, find the defect position in the sample by scanning, when the defect wave height is 80% of the full screen height, the attenuator gain of the instrument is 53dB. Obtain the A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com