Electro-corrosion prevention ADSS optical fiber erecting structure

An optical fiber and U-shaped technology, applied in the field of ADSS optical fiber erection structure, can solve problems such as electrical corrosion and optical cable breakage, achieve the effects of reducing costs, ensuring reliable operation, and solving electrical corrosion failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. The following embodiments are explanations of the present invention, but the present invention is not limited to the following embodiments.

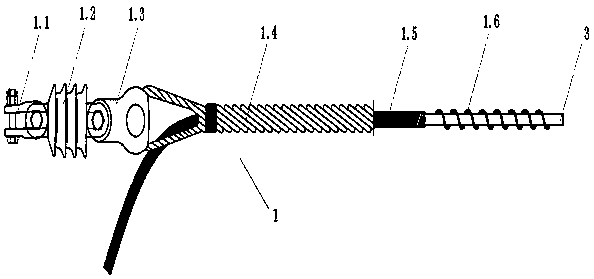

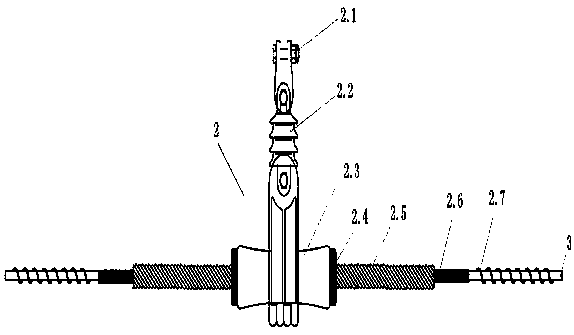

[0024] Such as figure 1 with 2 As shown, an anti-electric corrosion ADSS optical fiber erection structure provided by the present invention includes a corner tower fixture 1 and a tower pole fixture 2, and the corner tower fixture 1 includes a first U-shaped fitting 1.1, a first U One end of the type fitting 1.1 is fixed to the turret, the other end is connected to the first insulating ring 1.2, the first insulating ring 1.2 is fixedly connected with a heart-shaped connecting ring 1.3, and the heart-shaped connecting ring 1.3 is connected with a strain clamp 1.4, The ADSS optical cable 3 is arranged inside the tension clamp 1.4, and the outer layer of the ADSS optical cable 3 is provided with a tension inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com