Fermat's spiral based path planning method and system of bulb cutter with free curved surface

A tool path and helical line technology, applied in the field of free-form surface ball head tool path planning, can solve the problems of unfavorable tool life, processing quality to be improved, processing hard corners, etc., to improve processing efficiency and quality, and evenly distribute residual height , The effect of prolonging tool life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

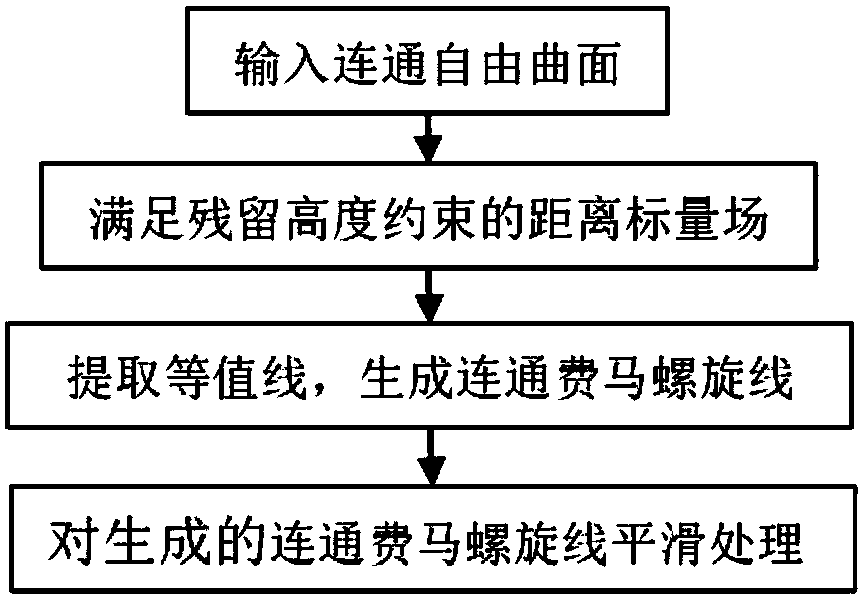

[0055] This embodiment discloses a free-form surface ball head tool path planning method based on the Fermat helix, such as figure 1 shown, including the following steps:

[0056] (1) For a given connected free-form surface S, calculate a distance scalar field that satisfies the uniform residual height constraint;

[0057] (2) Extract the contours in the scalar field calculated in step 1 to generate connected Fermat spirals;

[0058] (3) Under the constraint of the maximum residual height, the generated connected Fermat spirals are smoothed.

[0059] In described step (1), concrete steps include:

[0060] (1-1) Use the method of Keenan et al. to generate the initial distance field, such as figure 2 as shown in (a);

[0061] (1-2) Calculate the update field related to the residual height from the distance field;

[0062] (1-3) Superimpose the update field as a heterogeneous description into the distance field calculation, and recalculate the distance field;

[0063] (1-4...

Embodiment 2

[0093] The purpose of this embodiment is to provide a computing system.

[0094] A free-form surface ball head tool path planning system based on a Fermat helix, comprising a memory, a processor, and a computer program stored in the memory and operable on the processor, the processor implements the following steps when executing the program ,include:

[0095] receiving a connected free-form surface, and calculating a distance scalar field, which satisfies a uniform residual height constraint;

[0096] extracting contour lines in the distance scalar field to generate connected Fermat spirals;

[0097] Smooth the resulting connected Fermat helix subject to the maximum residual height constraint.

Embodiment 3

[0099] The purpose of this embodiment is to provide a computer-readable storage medium.

[0100] A computer-readable storage medium, on which a computer program is stored, and when the program is executed by a processor, the following steps are performed:

[0101] receiving a connected free-form surface, and calculating a distance scalar field, which satisfies a uniform residual height constraint;

[0102] extracting contour lines in the distance scalar field to generate connected Fermat spirals;

[0103] Smooth the resulting connected Fermat helix subject to the maximum residual height constraint.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com