Program automatic inspection method and system for body-in-white line body control program

A control program and automatic inspection technology, which is applied in the general control system, control/adjustment system, test/monitoring control system, etc., can solve the problems of hidden safety hazards of the line body, waste of man-hours, prone to missing or wrong inspections, etc. Achieve the effect of saving labor cost, avoiding missed or wrong detection, automatic program automatic inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

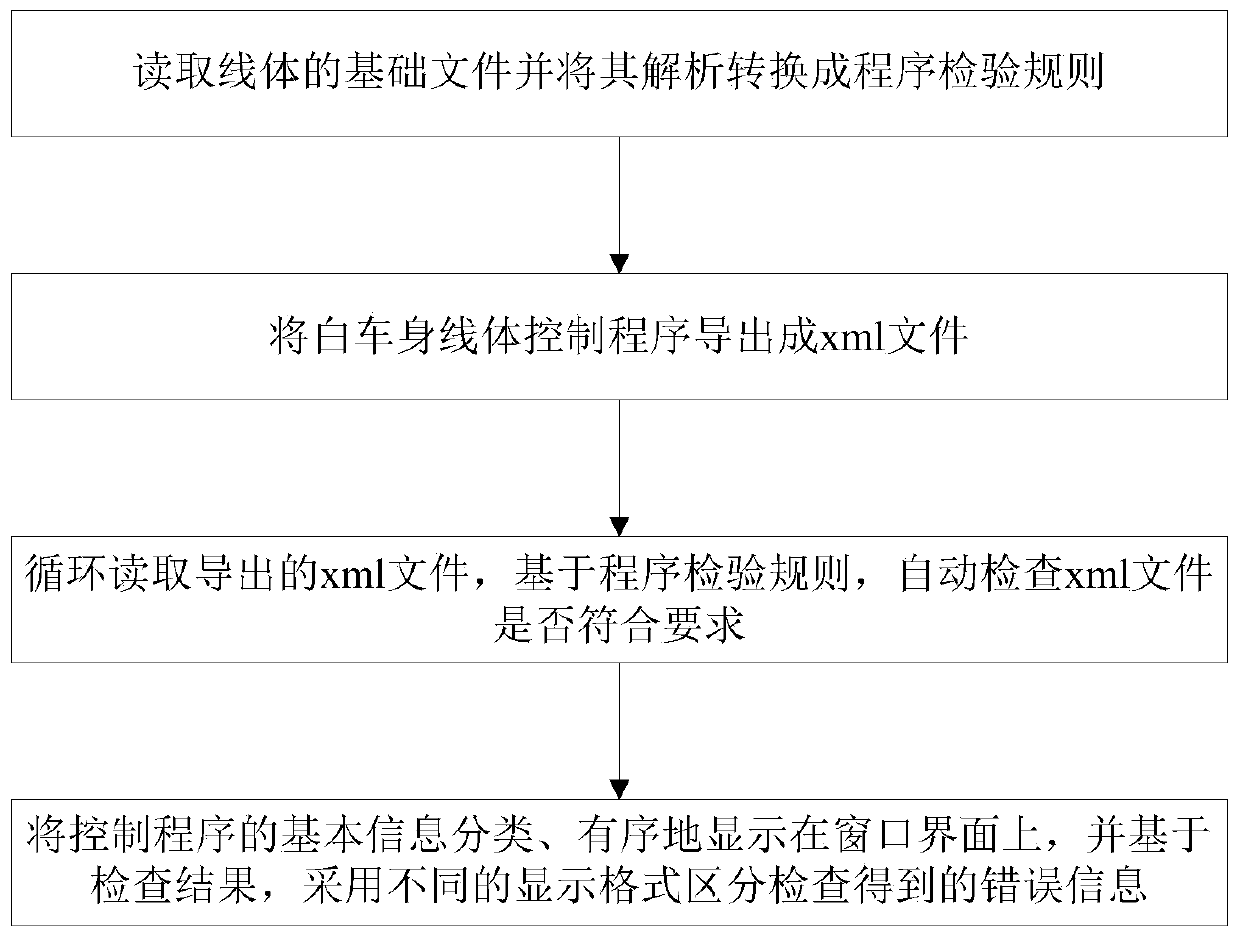

[0044] refer to figure 1 , the present invention provides a program automatic inspection method for the body-in-white line body control program, comprising the following steps:

[0045] Read the basic file of the line body and convert it into program inspection rules;

[0046] Exporting the body-in-white body control program into an xml file; the xml file includes the xml information of the following basic information of the control program: hardware configuration, symbol table, function block and program structure;

[0047] Circularly read the exported xml file, and automatically check whether the xml file meets the requirements based on the program inspection rules;

[0048] The basic information of the control program is classified and displayed on the window interface in an orderly manner, and based on the inspection results, different display formats are used to distinguish the error information obtained from the inspection.

[0049] Here, the different display formats ...

Embodiment 2

[0083] On the basis of the first method embodiment, this embodiment describes the detailed operation process in the process of automatically checking the body-in-white line body control program from the perspective of user operation:

[0084] 1. Fill in the basic information of the project

[0085] 1) Operation purpose: fill in the basic information of the project and reduce the error rate of program inspection. If the project naming and program naming meet the standards, there is no need to fill in the "station name", "line body name" and "project number" repeatedly;

[0086] 2) Operation requirements: fill in the "station name", "line body name", "item number" and "project name"; among them, "station name" and "line body name" are used for program inspection, and "item number" , "Project Name" is used to remark relevant information when exporting error reports;

[0087] 3) Startup method: fill in the project information one by one, and complete the modification after filli...

Embodiment 3

[0127] On the basis of method embodiment 1, this embodiment describes the detailed steps in the process of automatic program inspection of the body-in-white body control program from the perspective of automatic program processing:

[0128] The specific implementation of the code

[0129] 1. Connect to the Siemens Portal program, that is, the Siemens TIA Portal program mentioned in the background technology. After opening the Portal program, the program automatic inspection tool obtains the Portal process through Openness; after obtaining the process, connect to the current Portal project. If the project is not based on TIA Portal V14SP1 or if the process is not acquired, an alarm is output. After connecting to the Portal project, obtain the software program information in the project through traversal.

[0130] 2. Obtain hardware configuration information: After the program is successfully connected, the program automatic inspection tool first obtains all hardware configura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com