Method for forming an air gap between metal wiring lines and a metal wiring structure

A metal connection and air gap technology, which is applied in the direction of electrical components, electric solid devices, circuits, etc., can solve the problems of short circuit of metal connection, short circuit of metal connection with small spacing, influence on the structure and shape of the side wall of metal connection, etc. , to avoid short circuits, overcome cracks, and achieve good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in detail below in conjunction with accompanying drawing:

[0034] An embodiment of the present invention provides a method for forming an air gap between metal wirings, including the following steps:

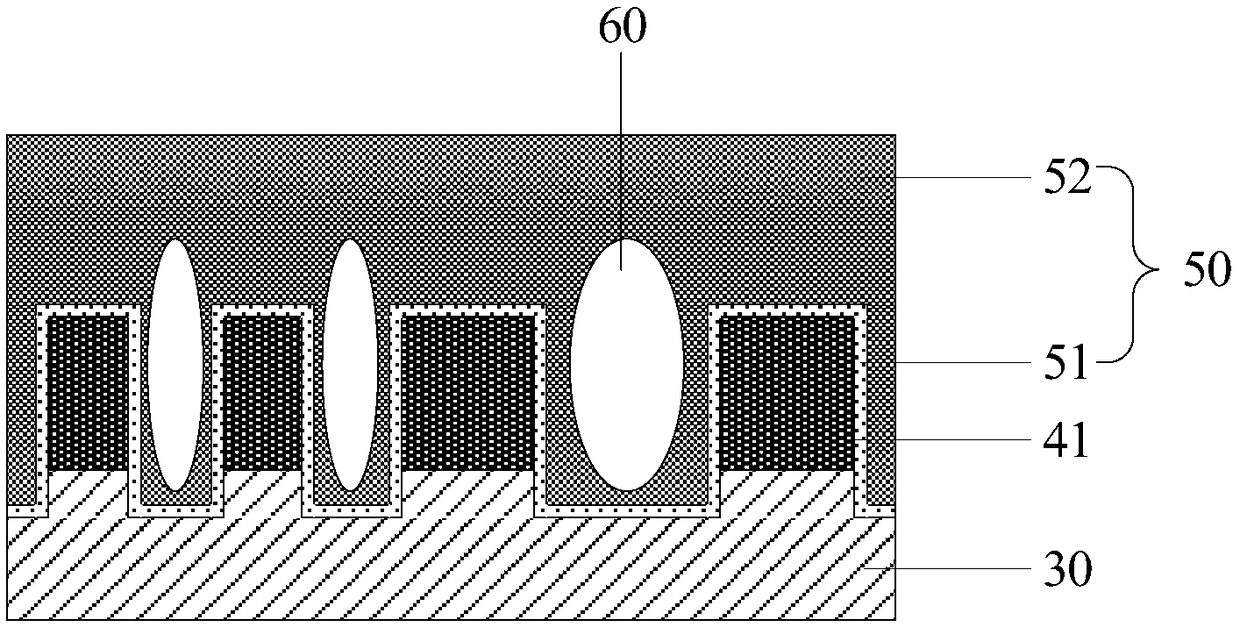

[0035] Step 101, please refer to Figure 5 , an inter-metal dielectric layer 300 is provided, and the material of the inter-metal dielectric layer 300 is an alternative material such as silicon dioxide. Among them, the inter-metal dielectric layer can be the dielectric layer under the bottom metal layer, which is called an inter-layer dielectric layer (Inter Layer Dielectric, ILD), or it can be the dielectric layer under the top and middle metal layers, called an inter-metal layer. Medium layer (Inter Metal Dielectric, IMD).

[0036] Step 102, please refer to Figure 5 , forming a metal layer (Metal) 400 on the inter-metal dielectric layer 300; the metal layer 400 is aluminum.

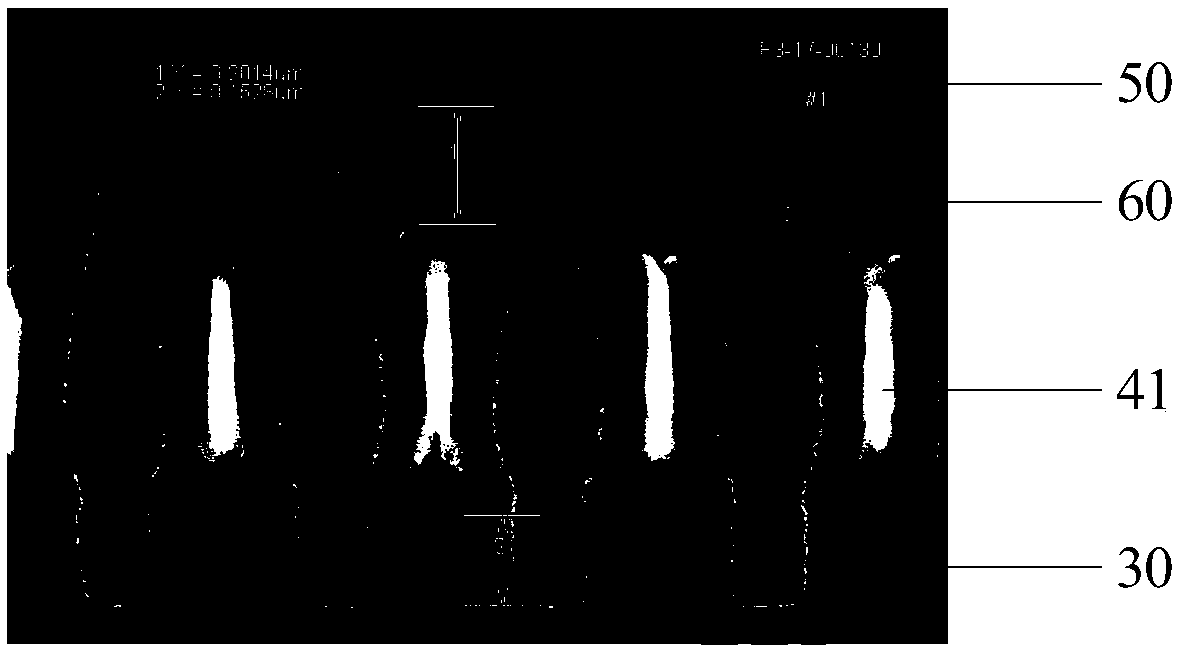

[0037] Step 103, please refer to Figure 6 and Figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com