Motor rotor and a brushless motor applying the same

A technology of motor rotor and brushless motor, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problems of low cost of permanent magnets, large torque ripple, etc., and achieve material saving, stable torque output, and easy assembly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

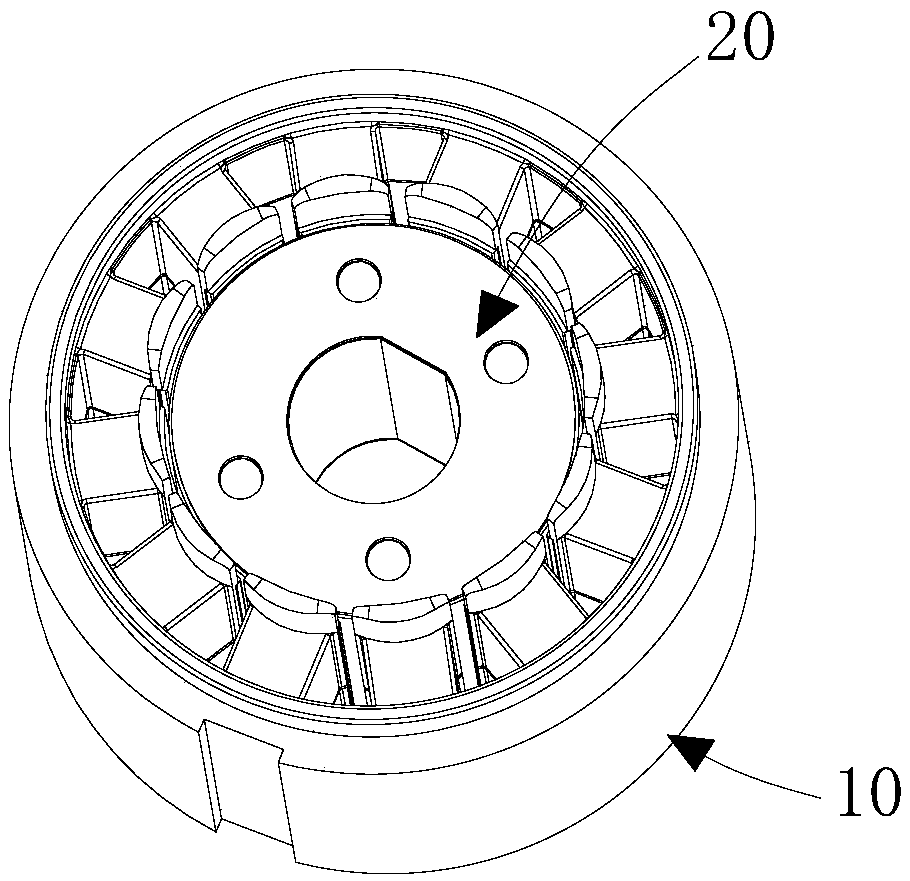

[0021] refer to figure 1 , a brushless motor provided by the present invention, the brushless motor is especially suitable for a compressor of an electric vehicle. The brushless motor includes a motor stator 10 and a motor rotor 20 installed in the motor stator 10 . Because the main improvement of the present invention is in motor rotor 20, so figure 1 The structure of the motor is shown simplified.

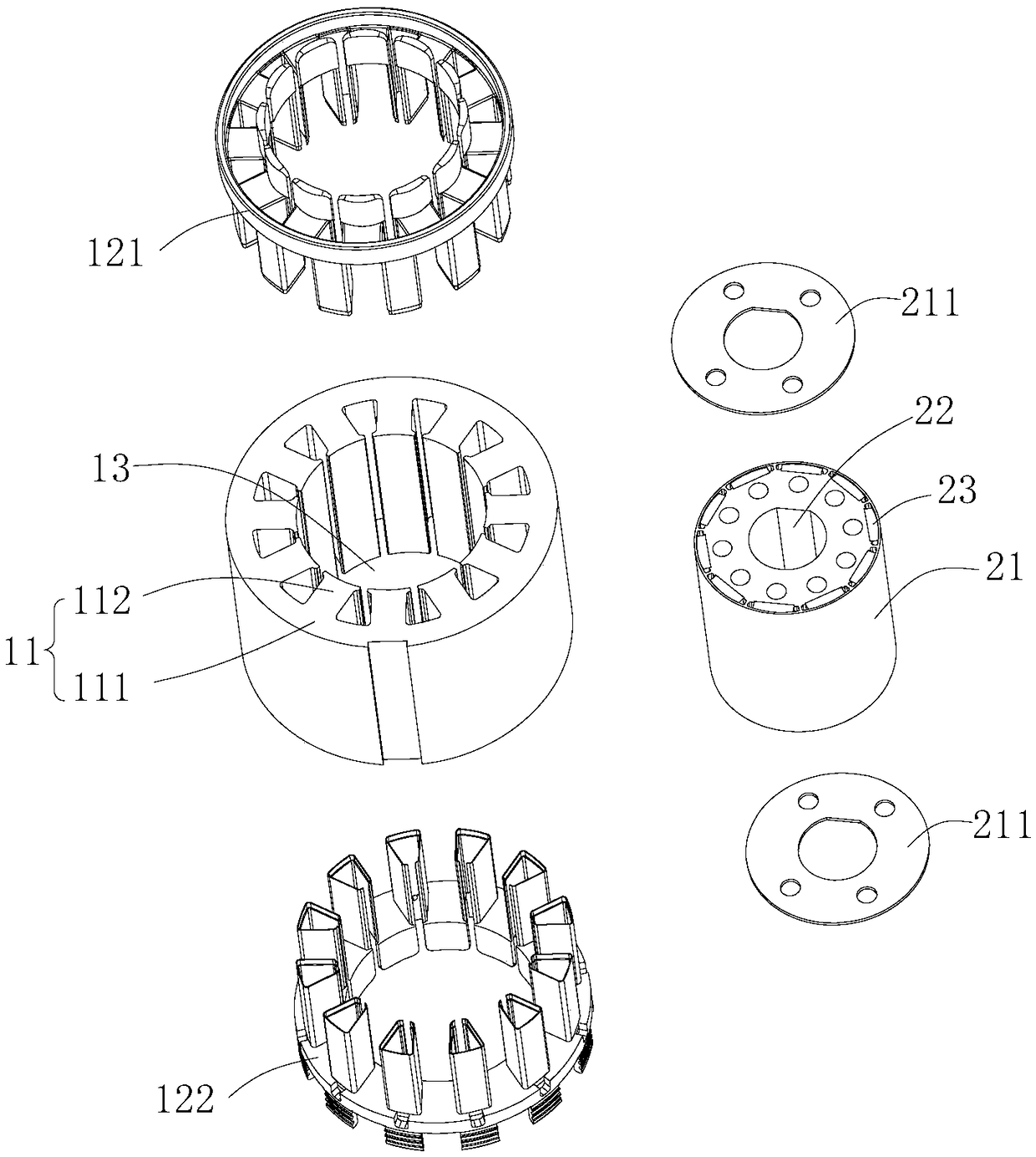

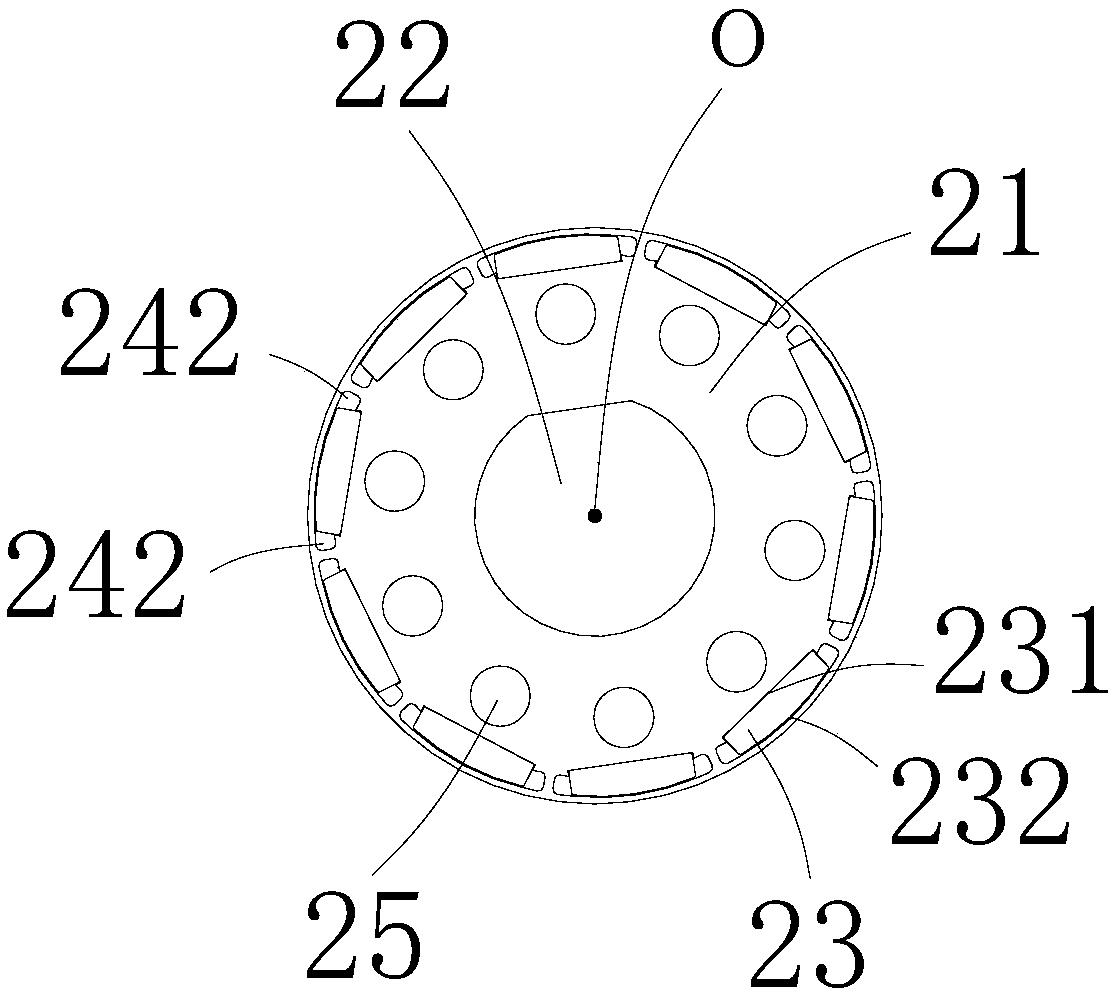

[0022] refer to figure 2 The motor stator 10 includes a stator core 11, a winding (not shown) wound to the stator core 11 and an insulating frame 121 installed on the two axial ends of the stator core 11 for insulating the stator core 11 and the winding , 122. The stator core 11 includes an annular yoke portion 111 and a plurality of stator teeth 112 protruding inward from the yoke portion 111 , and the above-mentioned windings are wound on the plura...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com