Cleaning machine, system and method for transfer of front and rear rows of tiled roof photovoltaic power stations

A technology of photovoltaic power station and cleaning machine, which is applied in the direction of cleaning methods using tools, photovoltaic power generation, chemical instruments and methods, etc., to achieve the effects of easy implementation and control, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

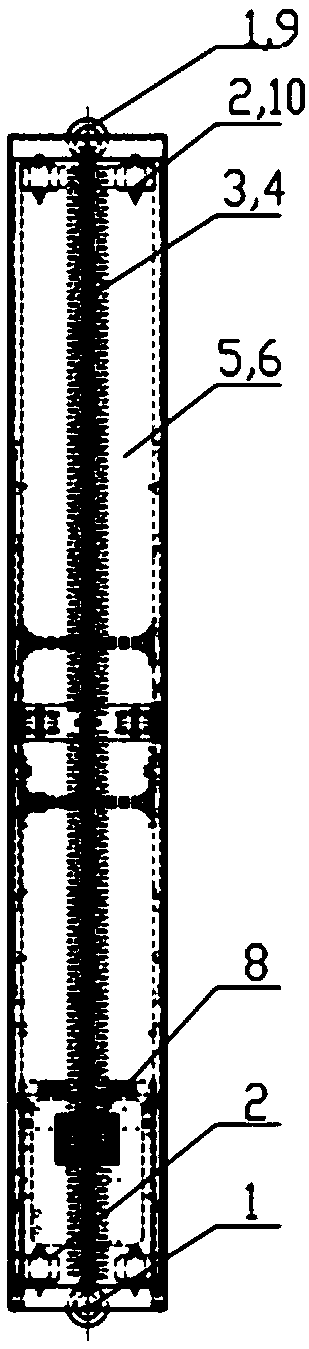

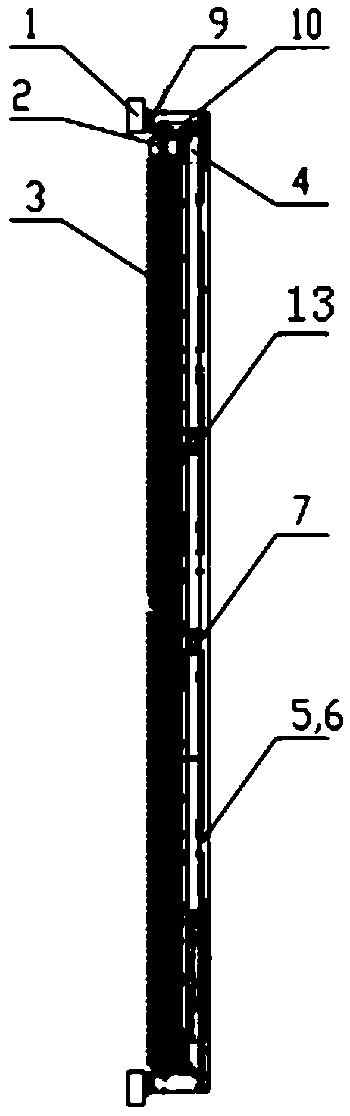

[0068] like Figure 1-12 As shown, the embodiment of the present invention provides a cleaning machine for transferring the front and rear rows of a flat roof photovoltaic power station, including a frame 5, a cleaning device and a guide device, and the cleaning device and the guide device are installed on the frame 5, the cleaning machine also includes: a control system, a steering system and a positioning module, and the control system, the steering system and the positioning module are all installed on the frame 5;

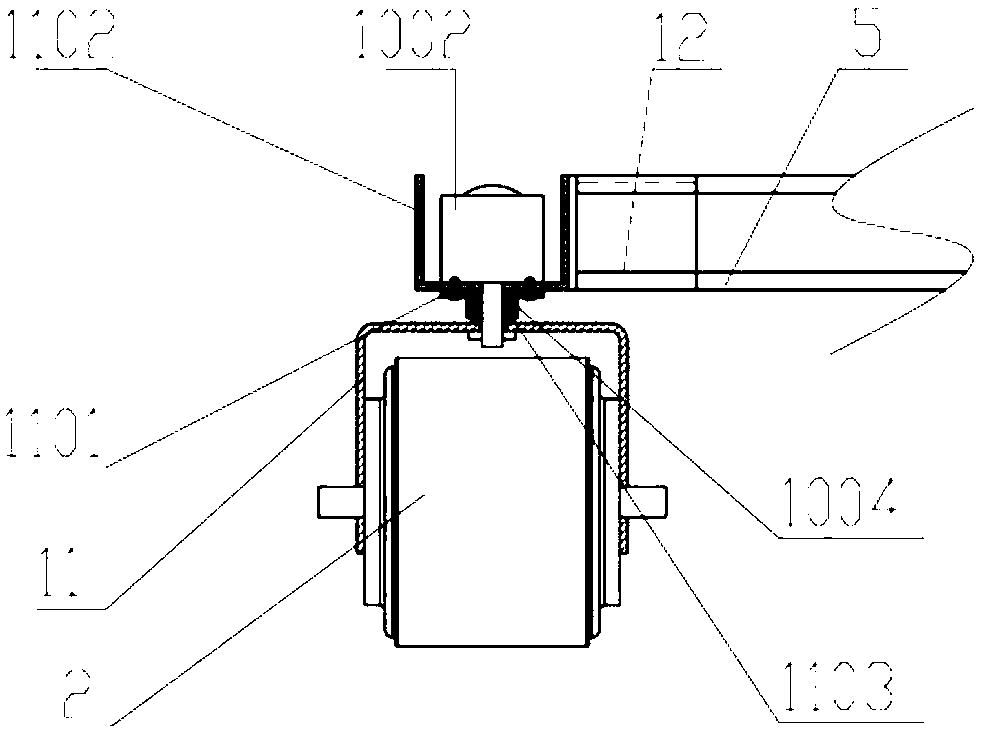

[0069] The steering system includes a steering motor 1002, a transmission system and a running gear, and the steering motor 1002 drives the running gear through the transmission system to turn, and the steering motor 1002 and the running gear both pass through the transmission system and The frame 5 is connected;

[0070] The steering motor 1002, the running gear and the positioning module are all connected to the control system data, and the control system co...

Embodiment 2

[0121] An embodiment of the present invention provides a sweeping machine system for transferring front and rear rows of a tiled roof photovoltaic power station, including the sweeping machine described in Embodiment 1 and the over-row guide rail system (such as Figure 12 As shown), the cleaning machine completes the transfer of the front and rear rows along the over-row guide rail system; the over-row guide rail system includes: horizontal guide rails 1303, longitudinal guide rails 1301 and transition guide rails 1302, and the starting end of each array assembly is set There is one transverse guide rail 1303, one end of each transverse guide rail 1303 is connected to the array assembly, and the other end is vertically connected to one of the longitudinal guide rails 1301, and a set is arranged between two array assemblies with a smaller distance. The transition guide rail 1302, the transition guide rail 1302 is vertically connected with the two adjacent transverse guide rails...

Embodiment 3

[0128] An embodiment of the present invention provides a cleaning method for transferring front and rear rows of a tiled roof photovoltaic power station, using the cleaning machine described in Embodiment 1 for cleaning, including the following steps:

[0129] S1, place the cleaning machine at the beginning of the current row of array components;

[0130] S2, use the control system to control the power-off self-locking of the steering motor, and control the power-on operation of the traveling device, and the cleaning machine starts to clean the current array components;

[0131] S3, when the cleaning machine reaches the end of the current array assembly, the positioning module is triggered for the first time and sends a signal to the control system. After receiving the signal, the control system controls the running device to rotate in reverse, and the cleaning machine returns to the current array the start of the component;

[0132] S4, the cleaning machine continues to move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com