Rubber cutting machine

A technology of glue cutting machine and cutting mechanism, which is applied in metal processing and other directions, can solve the problems of rough cutting of glue, achieve precise cutting, solve the problem of rough cutting of glue, and operate safely and conveniently

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

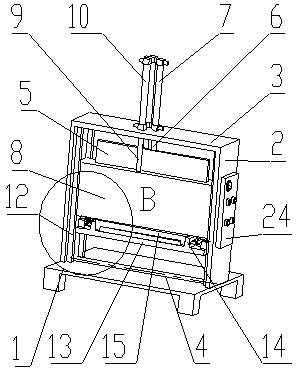

[0035] see Figure 3-6 , The embodiment of the present invention provides a glue cutting machine, including a base 1, a bracket arranged on the base 1, a cutting mechanism arranged on the bracket, a driving mechanism for driving the cutting mechanism, and a control mechanism.

[0036] The bracket is a door-shaped frame composed of two columns 2 and a crossbeam 3, the bracket is arranged in the front and back direction of the base 1 near the middle, and the bottom ends of the two columns 2 are respectively fixed on the left and right sides of the upper end surface of the base 1;

[0037] A backing plate 4 is arranged between the two columns 2 on the upper end of the base 1; the backing plate 4 is a nylon backing plate or a polyurethane backing plate;

[0038] The cutting mechanism includes a cutter 5 arranged on the bracket, a cutter connecting rod 6 is arranged on the upper end surface of the cutter 5 near the middle part, a first piston cylinder 7 is arranged on the upper end...

Embodiment 2

[0051] see figure 1 , figure 2 and Figure 5 , the embodiment of the present invention provides a glue cutting machine, including a base 1, a bracket arranged on the base 1, a cutting mechanism arranged on the bracket, a driving mechanism for driving the cutting mechanism, and a control mechanism, and protective mechanisms are arranged on both sides of the bracket .

[0052] The bracket is a door-shaped frame composed of two columns 2 and a crossbeam 3, the bracket is arranged in the front and back direction of the base 1 near the middle, and the bottom ends of the two columns 2 are respectively fixed on the left and right sides of the upper end surface of the base 1;

[0053] A backing plate 4 is arranged between the two columns 2 on the upper end of the base 1; the backing plate 4 is a nylon backing plate or a polyurethane backing plate;

[0054] The cutting mechanism includes a cutter 5 arranged on the bracket, a cutter connecting rod 6 is arranged on the upper end surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com