Simple full-automatic gasket die-cutting machine

A fully automatic, die-cutting machine technology, used in metal processing and other directions, can solve problems such as high cost, complex after-sales maintenance, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

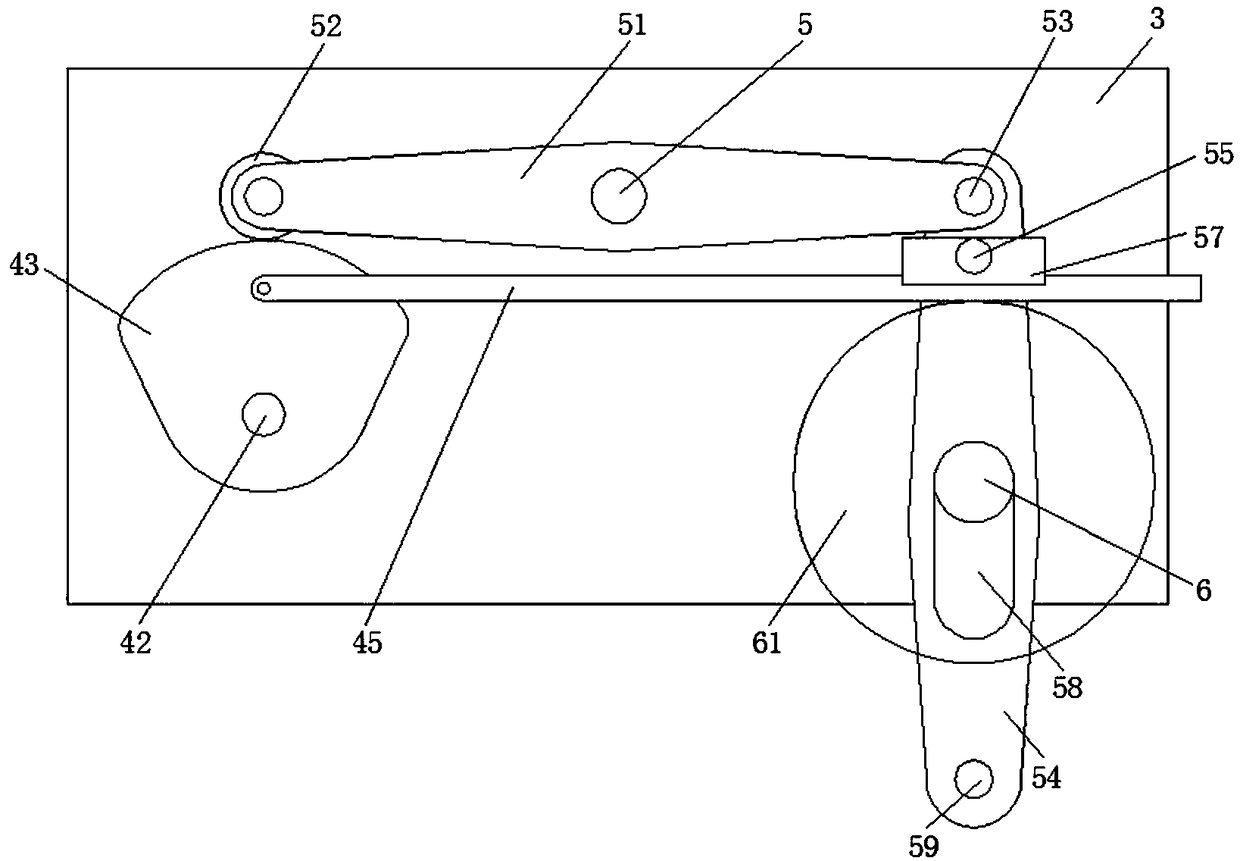

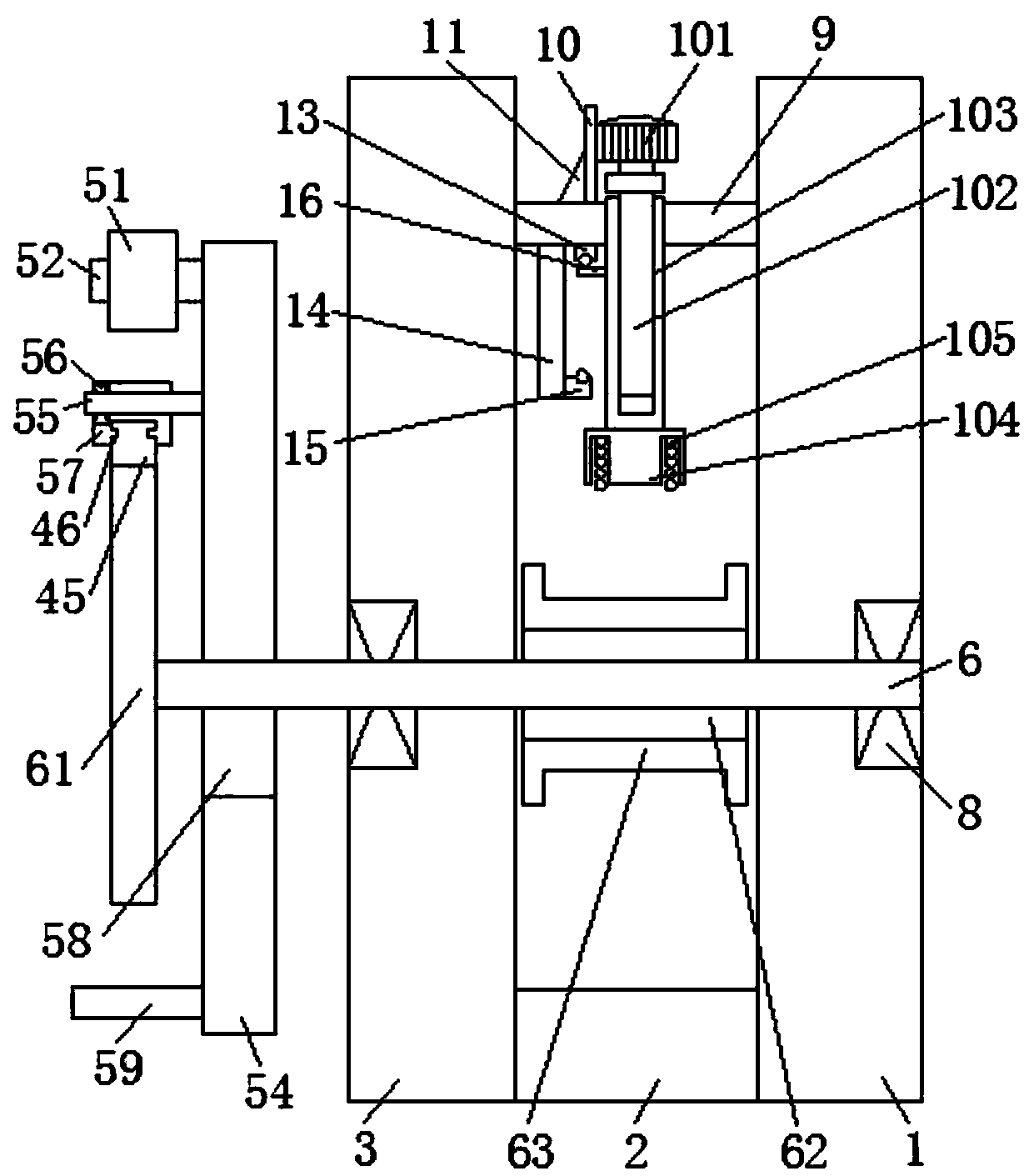

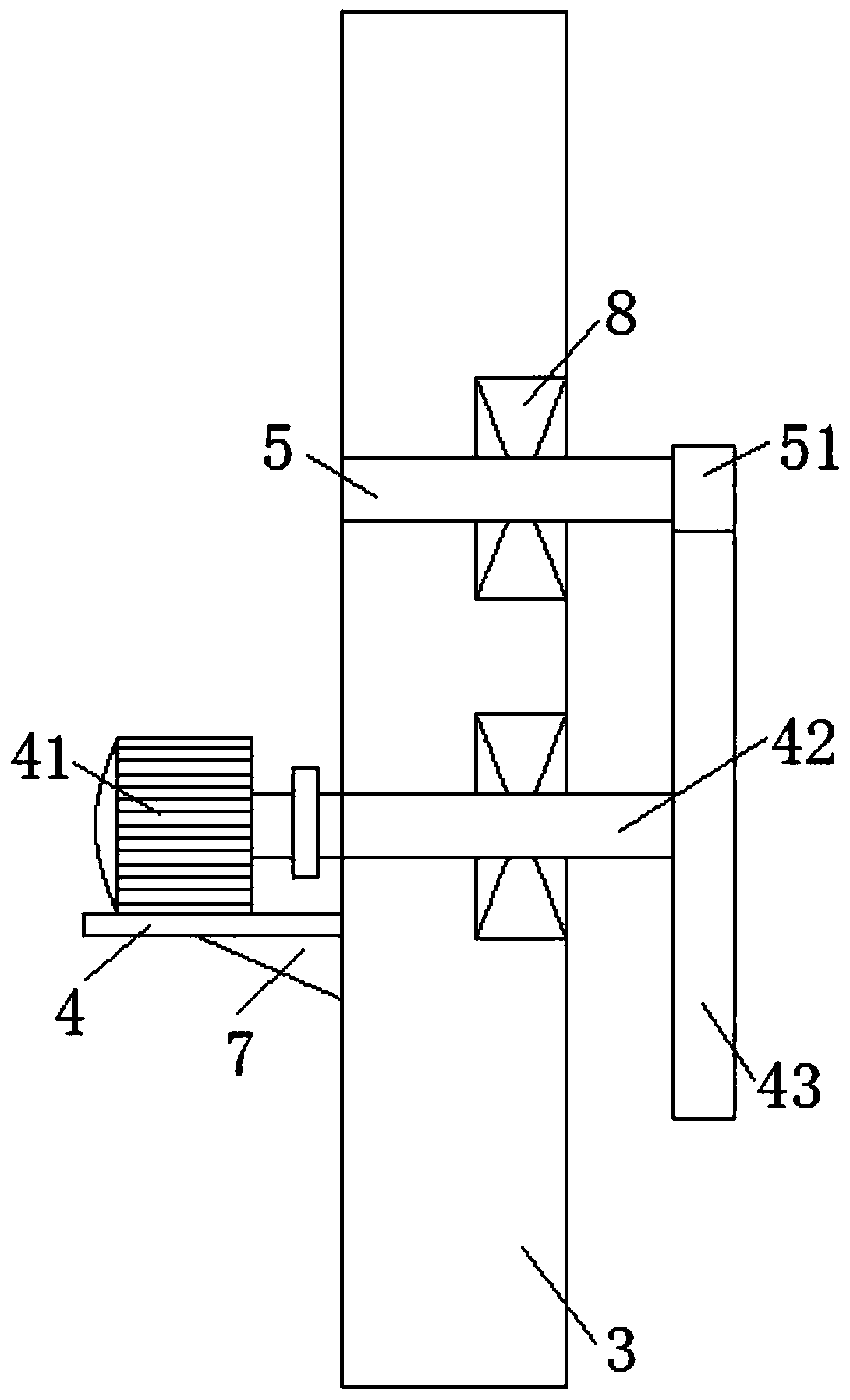

[0021] refer to Figure 1-4, a simple automatic gasket die-cutting machine, including a first support plate 1, the surface of the first support plate 1 is fixedly connected with a reinforcement leg 2, and one end of the reinforcement leg 2 is fixedly connected with a second support plate 3, the second The surface of the second support plate 3 is provided with a transmission device, and the transmission device includes a first motor base plate 4, a swing rod shaft 5 and a gear shaft 6, and the surface of the first motor base plate 4 is fixedly connected with a first reinforcement plate 7, and the first reinforcement plate The surface of the plate 7 is fixedly connecte...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap