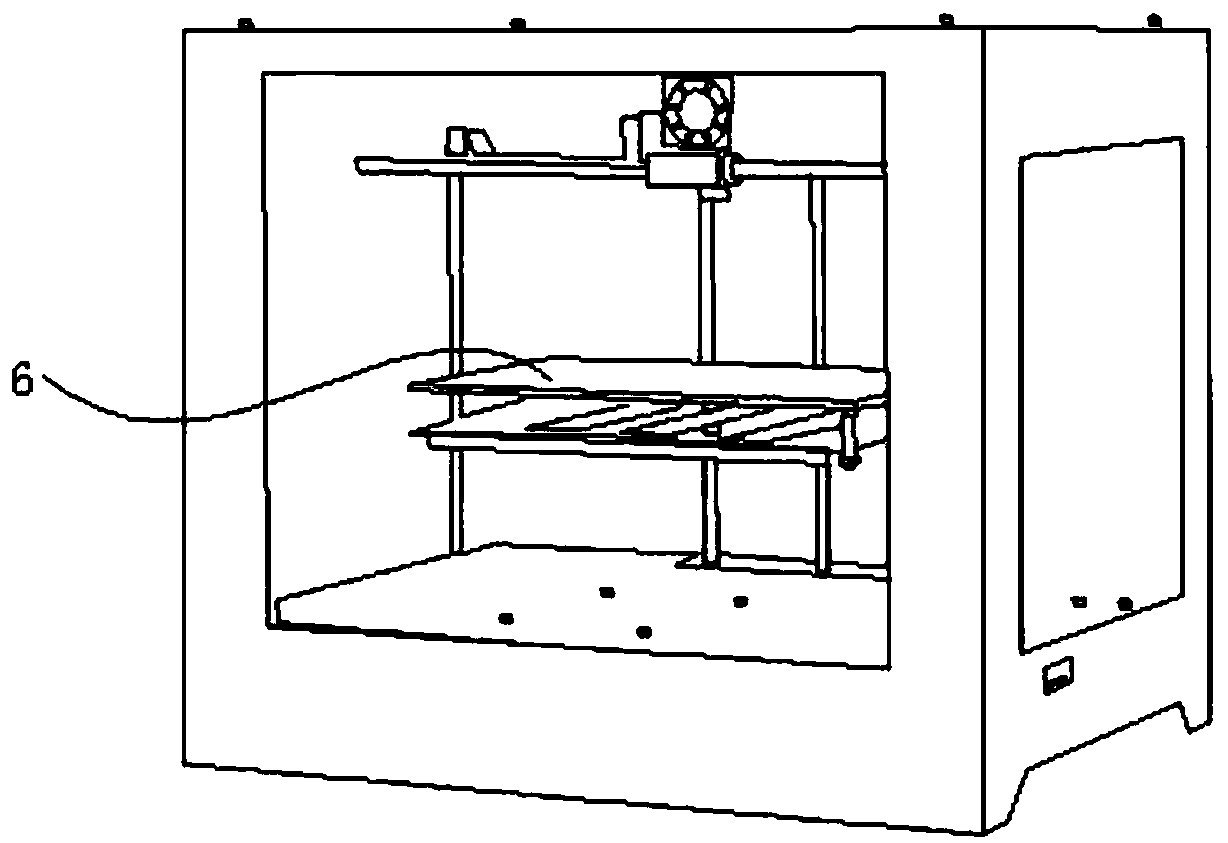

3D printing pad and 3D printer

A 3D printer and 3D printing technology, applied in the field of 3D printing, can solve the problems of low printing efficiency, difficult peeling of printed parts, and poor compatibility of magnetic materials in polar directions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

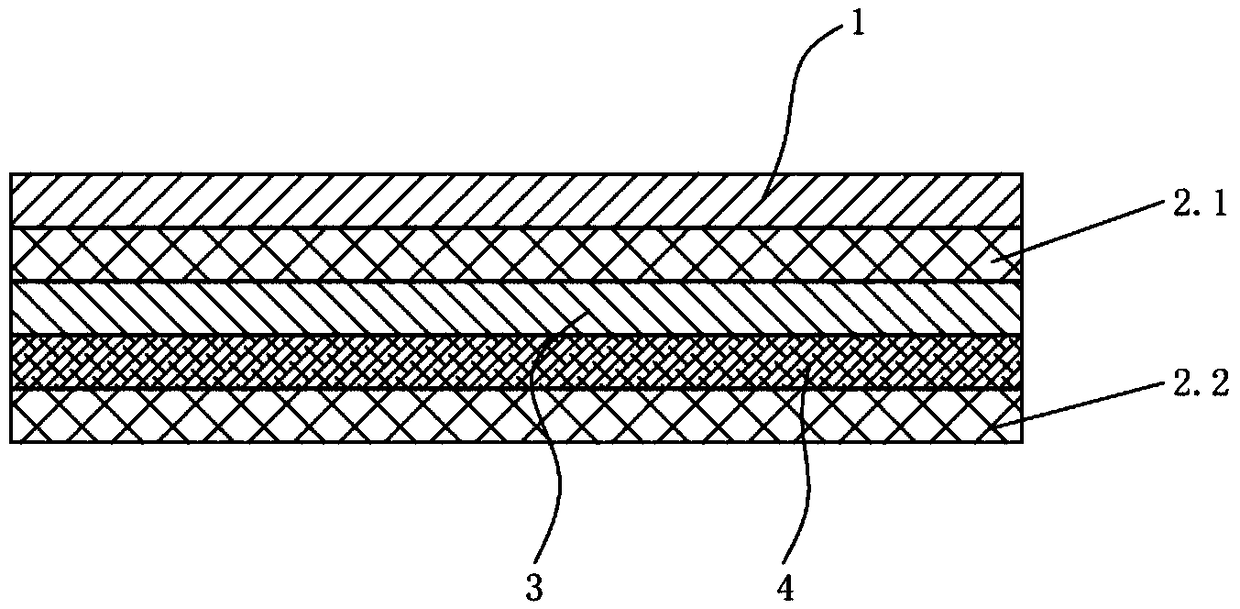

[0032] Such as figure 2 As shown, the 3D printing backing plate is applied to an aluminum-based printing hot bed, and consists of a surface layer 1, a double-sided adhesive layer 2.1, a ferromagnetic metal plate 3, a magnetic rubber sheet 4, and a double-sided adhesive layer 2.2. The surface layer 1, the double-sided adhesive layer 2.1 and the ferromagnetic metal plate 3 constitute the printing part, and the magnetic rubber sheet 4 and the double-sided adhesive layer 2.2 constitute the fixing part.

Embodiment 2

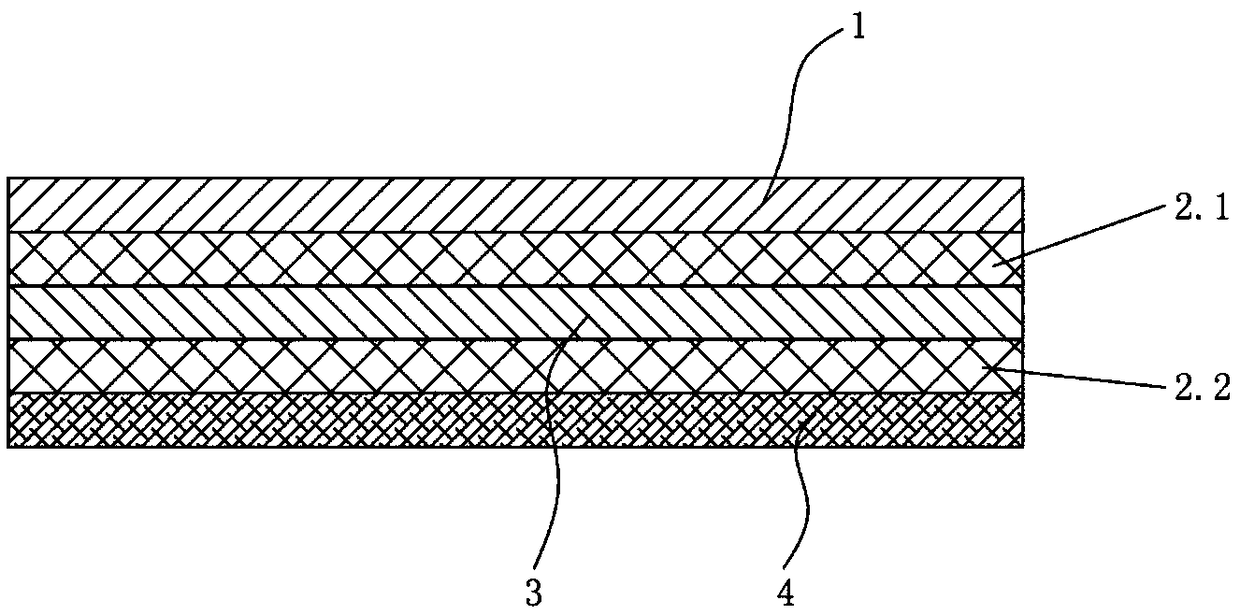

[0034] Such as image 3 As shown, the 3D printing backing plate is applied to the iron-based printing hot bed, and the printing part is composed of the surface layer 1, the double-sided adhesive layer 2.1, the ferromagnetic metal plate 3, the double-sided adhesive layer 2.2 and the magnetic rubber sheet 4.

Embodiment 3

[0036] Such as Figure 4 As shown, the 3D printing backing plate is applied to the aluminum-based printing hot bed, consisting of surface layer 1, double-sided adhesive layer 2.1, ferromagnetic metal plate 3.1, double-sided adhesive layer 2.2, magnetic rubber sheet 4, ferromagnetic metal plate 3.2 and double-sided The surface glue layer 2.3 is composed. The surface layer 1, the double-sided adhesive layer 2.1, the ferromagnetic metal plate 3.1, the double-sided adhesive layer 2.2 and the magnetic rubber sheet 4 form the printing part, and the ferromagnetic metal plate 3.2 and the double-sided adhesive layer 2.3 form the fixing part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com