Method for manufacturing high-transmittance curved cover plate

A technology with high transmittance and manufacturing method, applied in the field of touch screen and terminal, can solve the problems of low efficiency of silk screen printing ink, easy to be contaminated by ink, low transmittance of visual area, etc., so as to improve the quality and production efficiency. , to avoid pollution and improve the effect of transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

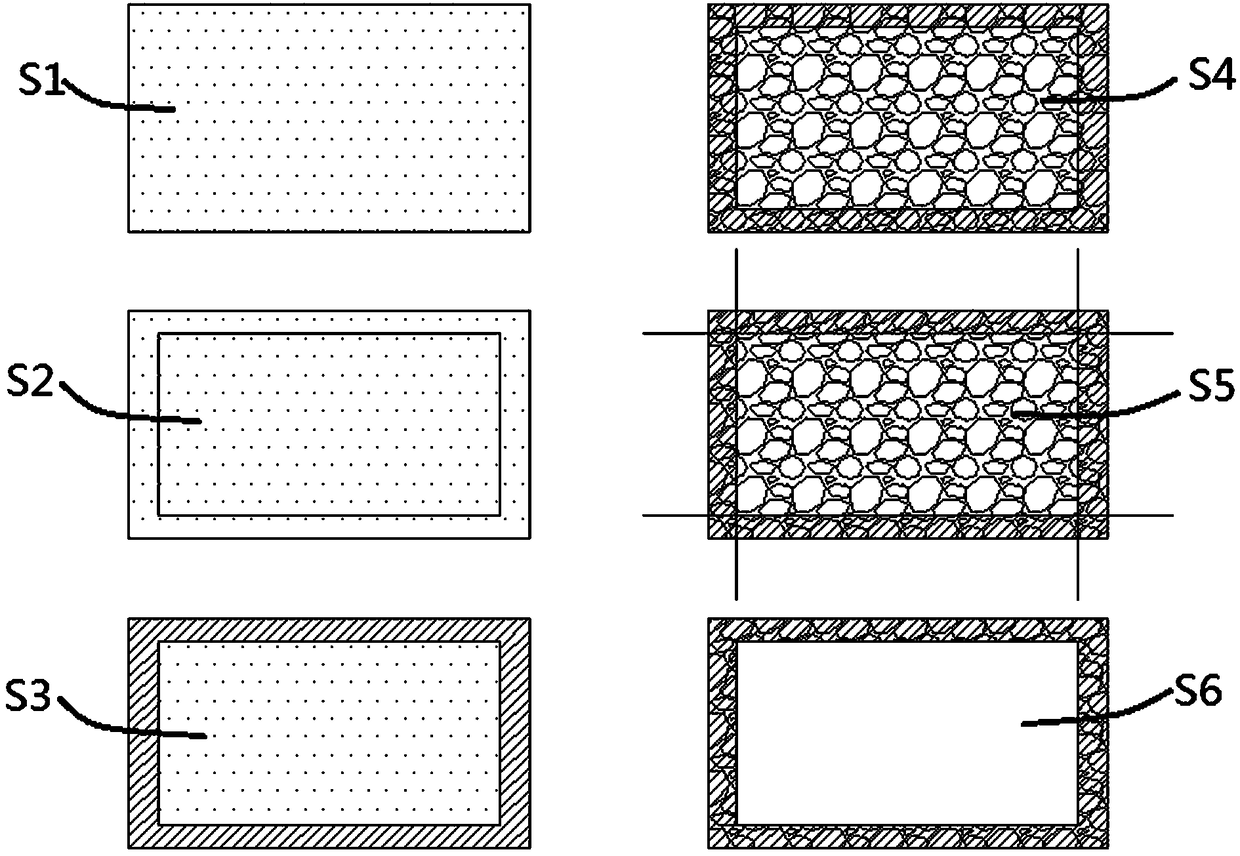

[0045] Such as figure 1 As shown, the method for manufacturing a high-transmittance curved cover plate provided in this embodiment is characterized in that it includes the following steps:

[0046] S1: Prepare a PET decorative film, and cut the decorative film to have the same surface area as the curved cover;

[0047] S2: Determine the position and size of the viewing area on the PET decorative film according to the viewing area position and size of the cover plate;

[0048] S3: Screen printing ink on the PET decorative film outside the viewing area to obtain a PET decorative film with silk screen printing ink outside the viewing area;

[0049] S4: OCA is fully bonded to the surface of the PET decorative film screen printing ink side;

[0050] S5: Use a laser die to cut off the viewing area of the PET decorative film to obtain a frame-shaped hollow screen printing ink PET decorative film;

[0051] S6: The frame-shaped hollow screen printing ink PET decorative film obtain...

Embodiment 2

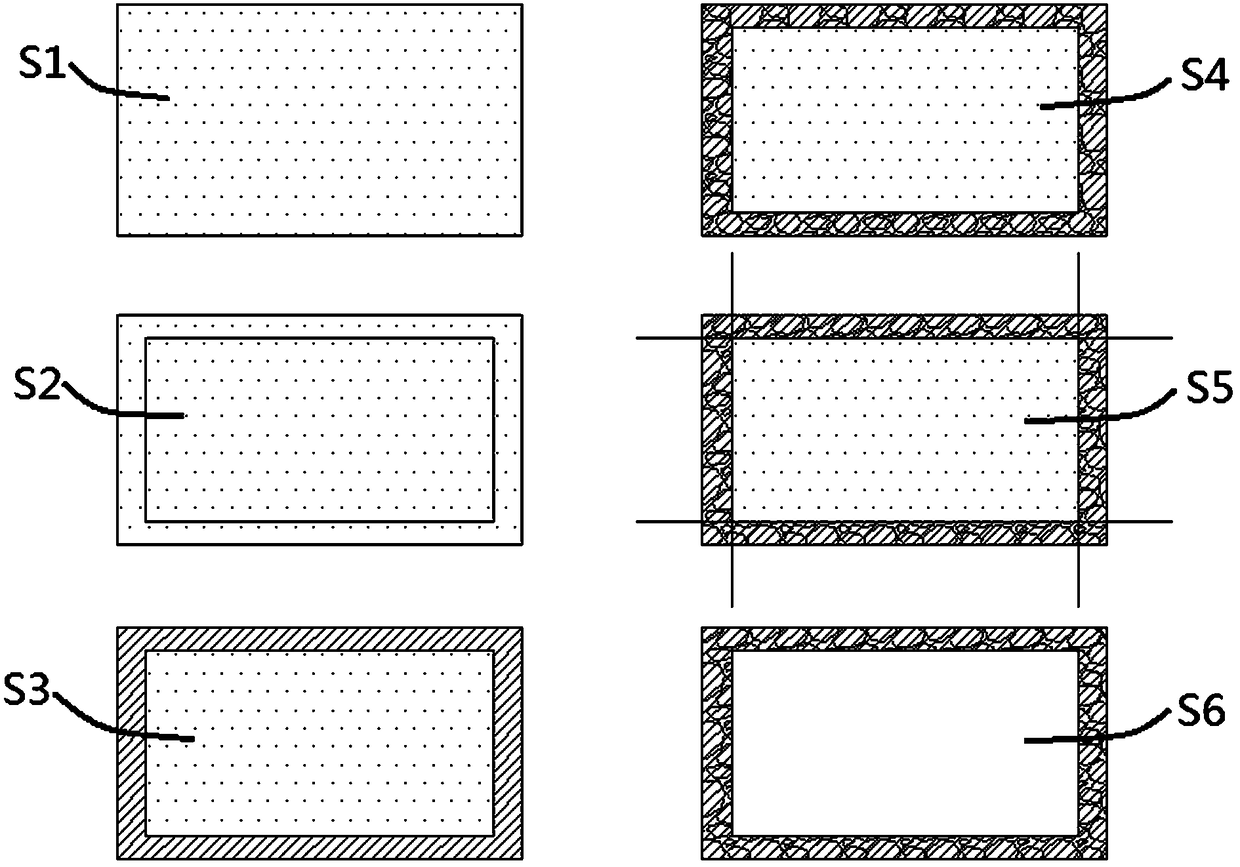

[0054] Such as figure 2 As shown, the method for manufacturing a high-transmittance curved cover plate provided in this embodiment is characterized in that it includes the following steps:

[0055] S1: Prepare a PC decorative film, and cut the decorative film to have the same surface area as the curved cover;

[0056] S2: Determine the position and size of the viewing area on the PC decorative film according to the viewing area position and size of the cover plate;

[0057] S3: screen printing ink on the area outside the viewing area of the PC decorative film to obtain a PC decorative film with silk screen printing ink outside the viewing area;

[0058] S4: Attach OCA to the surface of the screen printing ink side of the PC decorative film; where the OCA is attached only to the area outside the viewing area on the PC decorative film;

[0059] S5: Use a laser die to cut off the viewing area of the PC decorative film to obtain a frame-shaped hollow screen printing ink PC ...

Embodiment 3

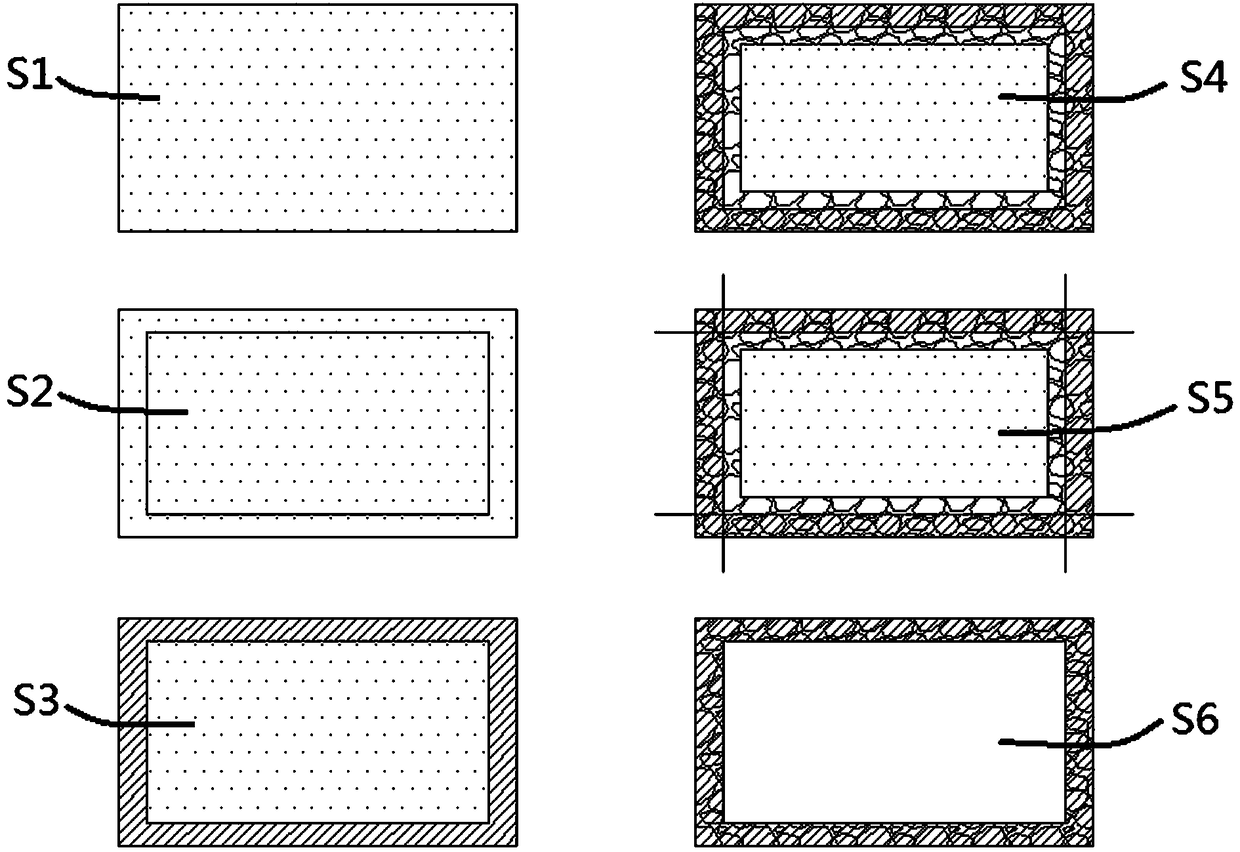

[0063] Such as image 3 As shown, the method for manufacturing a high-transmittance curved cover plate provided in this embodiment is characterized in that it includes the following steps:

[0064] S1: Prepare a COC decorative film, and cut the decorative film to have the same surface area as the curved cover;

[0065] S2: Determine the position and size of the viewing area on the COC decorative film according to the viewing area position and size of the cover plate;

[0066] S3: silk screen printing ink on the area outside the viewing area of the COC decorative film to obtain a COC decorative film with silk screen printing ink outside the viewing area;

[0067] S4: Attach OCA to the surface of the silk screen ink side of the COC decorative film; wherein, the OCA lamination is for the screen printing ink area and the 5mm extension from the edge of the screen printing ink area to the viewing area area;

[0068] S5: Use a laser die to punch out the viewing area of the COC ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com