Self-dumping transport vehicle

A transport vehicle and self-unloading technology, which is applied in the field of transport vehicles, can solve problems such as increasing the angle, and achieve the effect of avoiding the weight of the vehicle body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

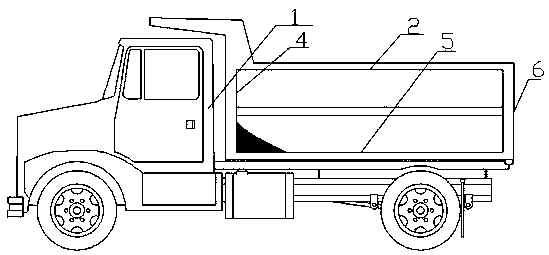

[0033] As a preferred embodiment of the application, refer to the attached Figure 1-3 , this example discloses:

[0034] Such as figure 1 As shown, the car body 2 of the existing engineering transport vehicle is made up of the bottom plate 5, the left side wall, the right side wall, the front side wall 4 and the rear side wall 6, and the rear side wall of the car body 2 rear flip transport vehicle 6. Both sides of the upper end are respectively hinged with the left side wall and the right side wall. When the bucket 2 is turned over, the rear side wall 6 is opened, and the material is formed between the rear side wall 6 and the bottom plate 5, the left side wall and the right side wall. Unloading at the opening, this method can conveniently tilt the material, but when this type of engineering transport vehicle is fully loaded, a large amount of material is accumulated in the body 2, if the transported material has a certain humidity or viscosity, such as clay or relatively I...

Embodiment 2

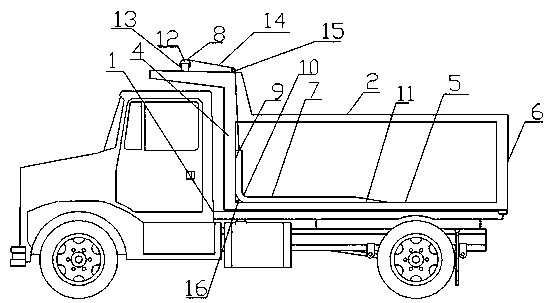

[0037] As another preferred embodiment of the present application, refer to the attached Figure 2-6 , this example discloses:

[0038] Such as figure 1 , figure 2 As shown, a self-unloading transport vehicle includes a car body 1, a car body 2 and a self-unloading driving device 3 for driving the car body 2 to turn backwards, and the car body 2 includes a front side wall 4, a bottom plate 5, a left side wall, the right side wall and the rear side wall 6, the rear end of the bucket 2 is hinged with the vehicle body 1; the dump driving device 3 is fixed on the vehicle body 1 and is located at the bottom of the bucket 2, The protruding end is hinged to the base plate 5; a stretching member 7 and a driving mechanism 8 for driving the movement of the stretching member 7 are arranged in the bucket 2, and the stretching member 7 includes a front side wall fitting portion 9, a curved part 10 and bottom plate connection part 11, the front side wall fitting part 9 of the stretching...

Embodiment 3

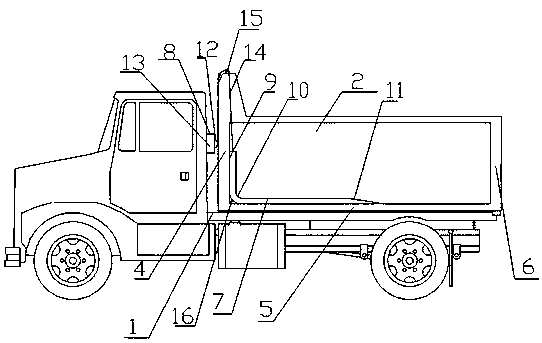

[0043] As another preferred embodiment of the present application, refer to the attached Figure 6 , this example discloses:

[0044] A self-unloading transport vehicle, comprising a car body 1, a car body 2 and a self-unloading driving device 3 for driving the car body 2 to turn backwards, the car body 2 includes a front side wall 4, a bottom plate 5, a left side wall, a right Side wall and rear side wall 6, the rear end of the vehicle bucket 2 is hinged with the vehicle body 1; It is hinged with the bottom plate 5; a stretching member 7 and a driving mechanism 8 for driving the movement of the stretching member 7 are arranged in the bucket 2, and the stretching member 7 includes a front side wall fitting part 9, a bending part 10 and a Bottom plate connecting portion 11, the front side wall fitting portion 9 of the stretching member 7 is attached to the front side wall 4, and moves along the front side wall 4 under the action of the driving mechanism 8; the bottom plate of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com