Fruit grade selecting and packing weighing device and system and treatment method

A weighing device and fruit technology, applied in packaging fruit/vegetables, packaging, packaging food, etc., can solve the problems of easy damage of high-quality fruit, inability to accurately control grading equipment, and many labors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

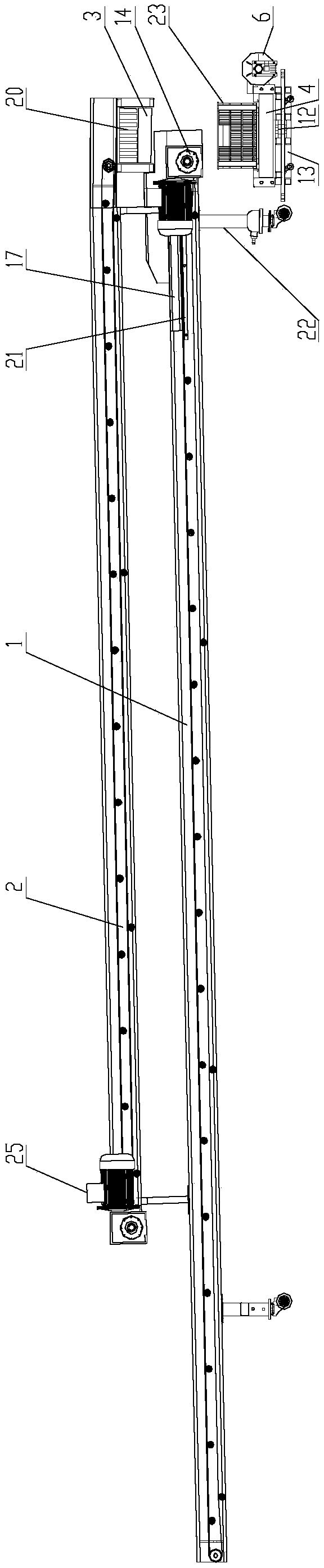

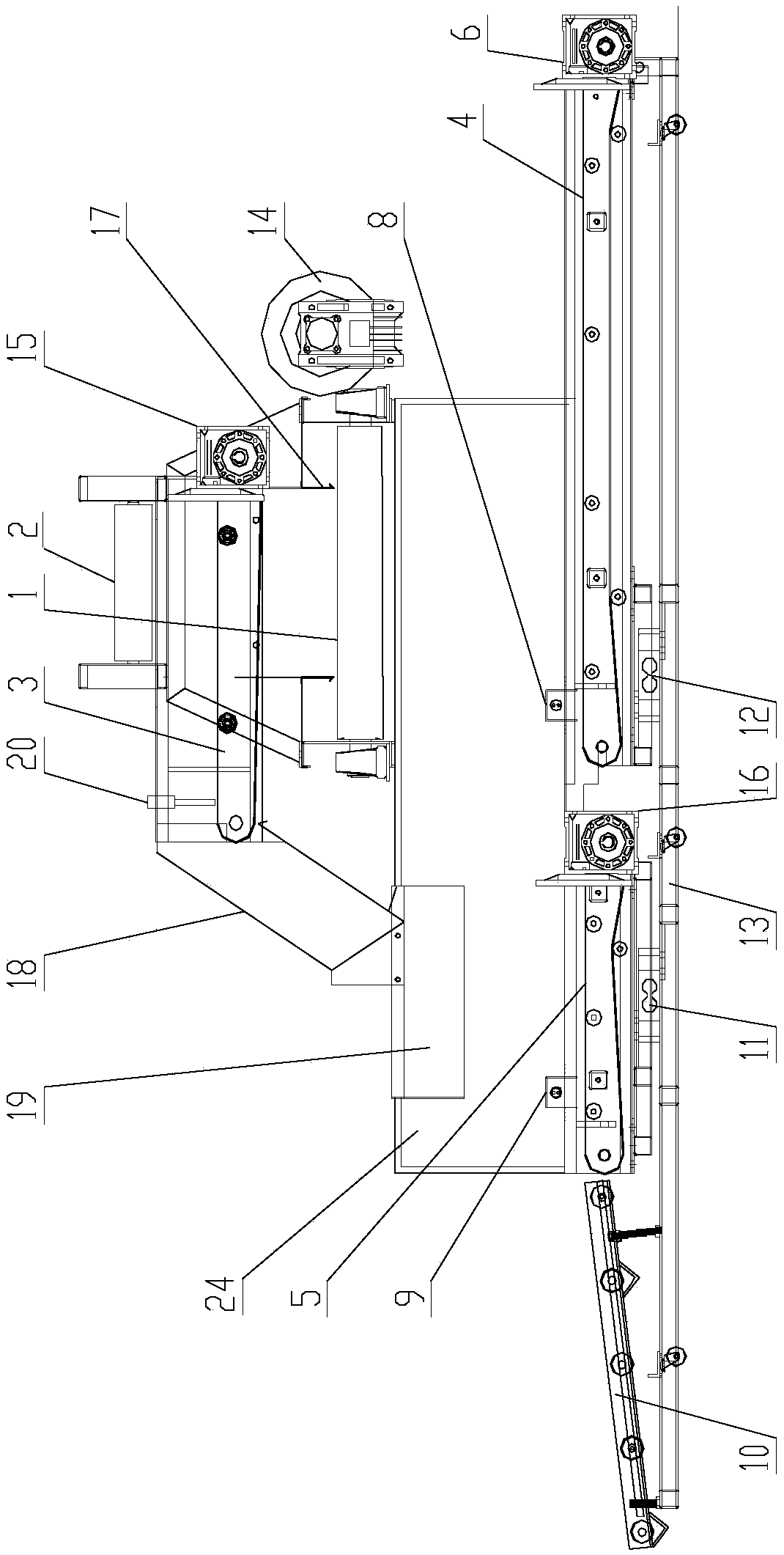

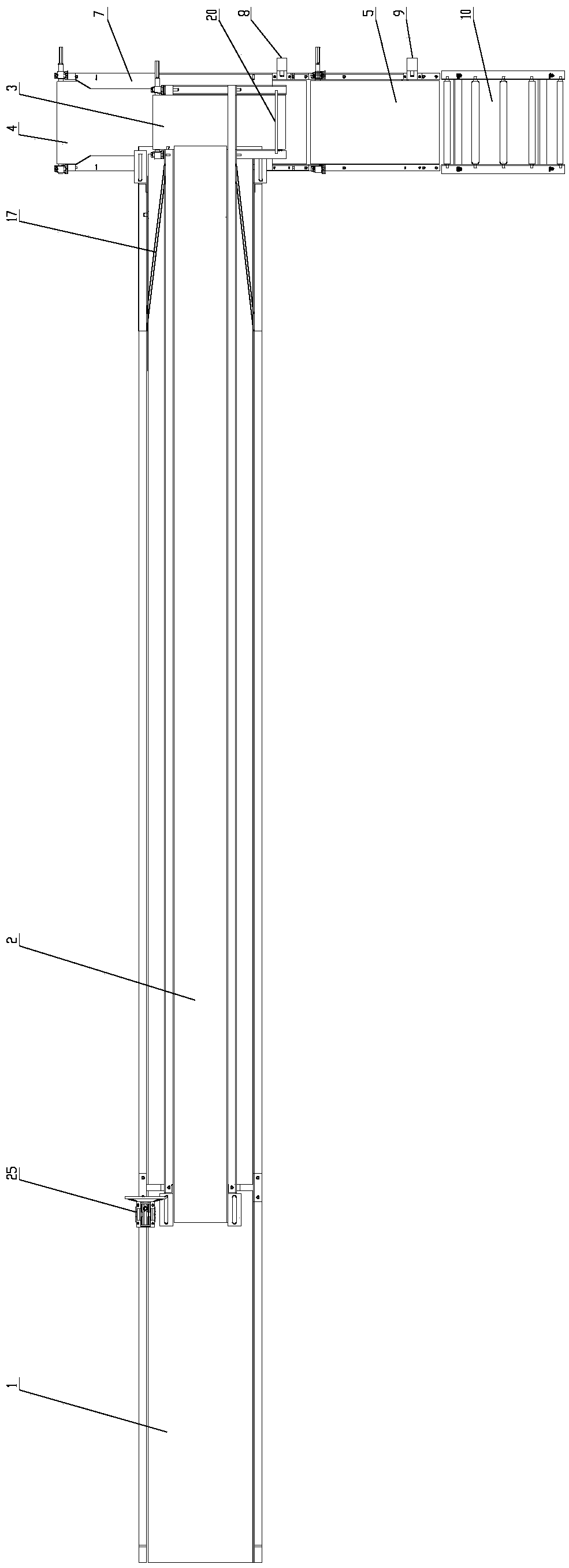

[0041] see Figure 1-6 , Embodiment 1 provides a fruit grading and packing weighing device, which includes a sorting part, a basket loading part and a control part. In the present embodiment, one side of the feeding and emptying fruit basket is defined as the beginning, and the other end is accordingly the end.

[0042] Wherein, the sorting part includes the fruit conveyor belt 1, the high-quality fruit conveyor belt 2 directly above the fruit conveyor belt 1, and the transfer conveyor belt 3 below the end of the high-quality fruit conveyor belt 2, etc. Wherein, the fruit delivery conveyor belt 1 protrudes relative to the high-quality fruit conveyor belt 2 on one or both sides (front and rear sides) for manual sorting, that is, the front and / or rear sides of the fruit delivery conveyor belt 1 are exposed for sorting. Specifically, the fruit delivery conveyor belt 1 is parallel to the high-quality fruit conveyor belt 2 and the centerline is located on the same vertical plane, ...

Embodiment 2

[0054] Embodiment 2 provides a fruit grading and packing weighing system, the system includes a grading device and at least one fruit grading and packing weighing device provided in Embodiment 1. Usually only need several fruit receiving structures 32 in the middle of the grading device to be provided with corresponding fruit grading and packing weighing devices.

[0055] Among them, see Figure 7 and 8 , the grading device includes a frame 26, a drive structure on the frame 26, a feed structure 31 on the front side of the frame 26, a pitch-variable drive shaft 27 with a spiral groove 29 on the left and right sides of the frame 26 top, and the frame 26 A plurality of fruit-receiving structures 32 arranged at intervals in the lower part and a plurality of grading rollers 28 arranged between two pitch-variable drive shafts 27 along the left and right direction. Wherein, the drive structure drives the variable-pitch drive shaft 27 to rotate (and further drives the classification ...

Embodiment 3

[0060] Embodiment 3 provides a kind of processing method of fruit grading and packing and weighing, and this method adopts the system that embodiment 2 provides, and this method comprises:

[0061] Adjust the fruit guide plate 33 of the grading device so that fruits of different sizes fall onto the corresponding fruit receiving structure 32, and the fruit receiving structure 32 sends the fruit to the fruit delivery conveyor belt 1 of the fruit grading and packing weighing device through or without the conveyor belt .

[0062] During the process of conveying the fruit by the fruit conveyor belt 1, the workers passing through one or both sides of the fruit (high-quality fruit) will select the fruit (high-quality fruit) that meets the requirements of high-quality fruit (such as better shape, no collision, better color or plump, etc.) Place on the high-quality fruit conveyor belt 2. The high-quality fruit conveyor belt 2 and the transfer conveyor belt 3 deliver the high-quality f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com