Grape grading device and method

A grading device and grape technology, which is applied in chemical instruments and methods, solid separation, wet separation, etc., can solve the problems of raw material differentiation, achieve the effects of fast grading speed, uniform sugar content in grapes, and low damage rate of grapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

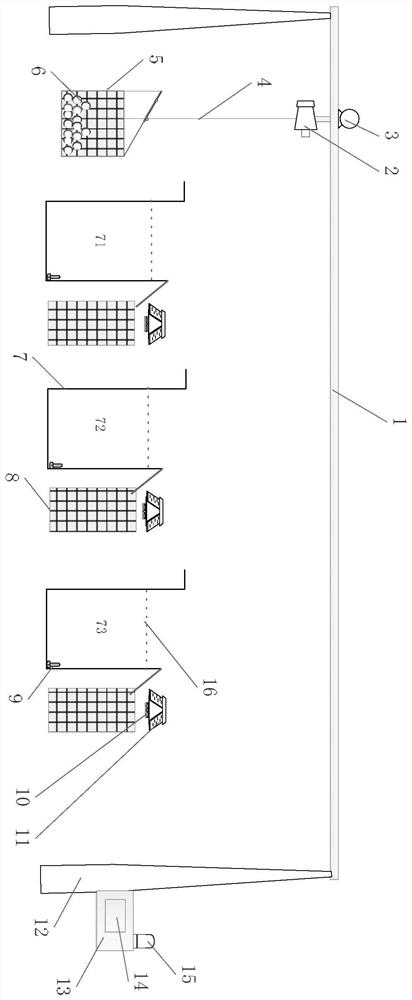

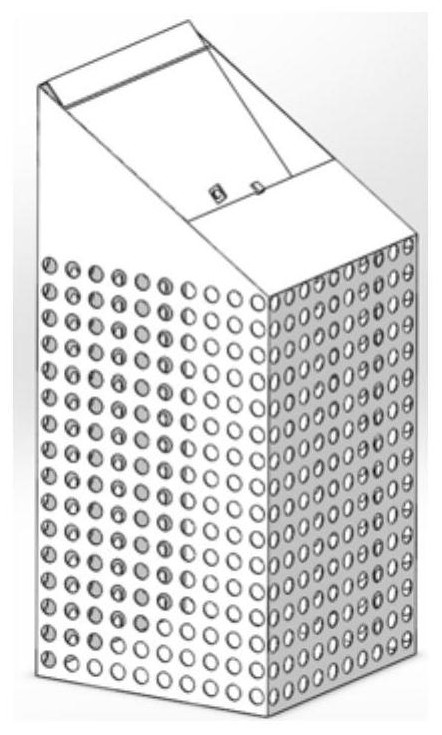

[0063] a) pick off the ripe grapes from the grapes, and remove impurities such as stems and leaves in the grape grains, and put them into the material frame 5;

[0064] b) Put the salt solution with a concentration of 100g / L, 130g / L, and 160g / L into the first suspension bucket 71, the second suspension bucket 72 and the third suspension bucket 73 respectively, and the density of the salt solution corresponds to 1069kg / m 3 , 1088kg / m 3 , 1100kg / m 3 ;

[0065] c) Start the grape separation device, according to the set program, the material box 5 is immersed in the first suspension bucket 71, the second suspension bucket 72 and the third suspension bucket 73 in turn, and the grape particles with low density float above the salt solution and are finally collected In the collection bucket 8;

[0066] d) After the separation process is completed, the main control unit is closed, the material frame 5 and the collection bucket 8 are opened, and the grapes after classification are t...

Embodiment 2

[0068] a) pick off the ripe grapes from the grapes, and remove impurities such as stems and leaves in the grape grains, and put them into the material frame 5;

[0069] b) Put the saline solution with a concentration of 130g / L, 160g / L, and 190g / L into the first suspension bucket 71, the second suspension bucket 72 and the third suspension bucket 73 respectively, and the density of the salt solution corresponds to 1088kg / m3 respectively 3 , 1100kg / m 3 , 1110kg / m 3 ;

[0070] c) Start the grape separation device, according to the set program, the material frame 5 is immersed in the first suspension bucket 71, the second suspension bucket 72 and the third suspension bucket 73 in sequence, and the grape particles with low density float above the salt solution and are finally collected into the corresponding collection bucket 8;

[0071] d) After the separation process is completed, the main control unit is closed, the material frame 5 and the collection bucket 8 are opened, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com