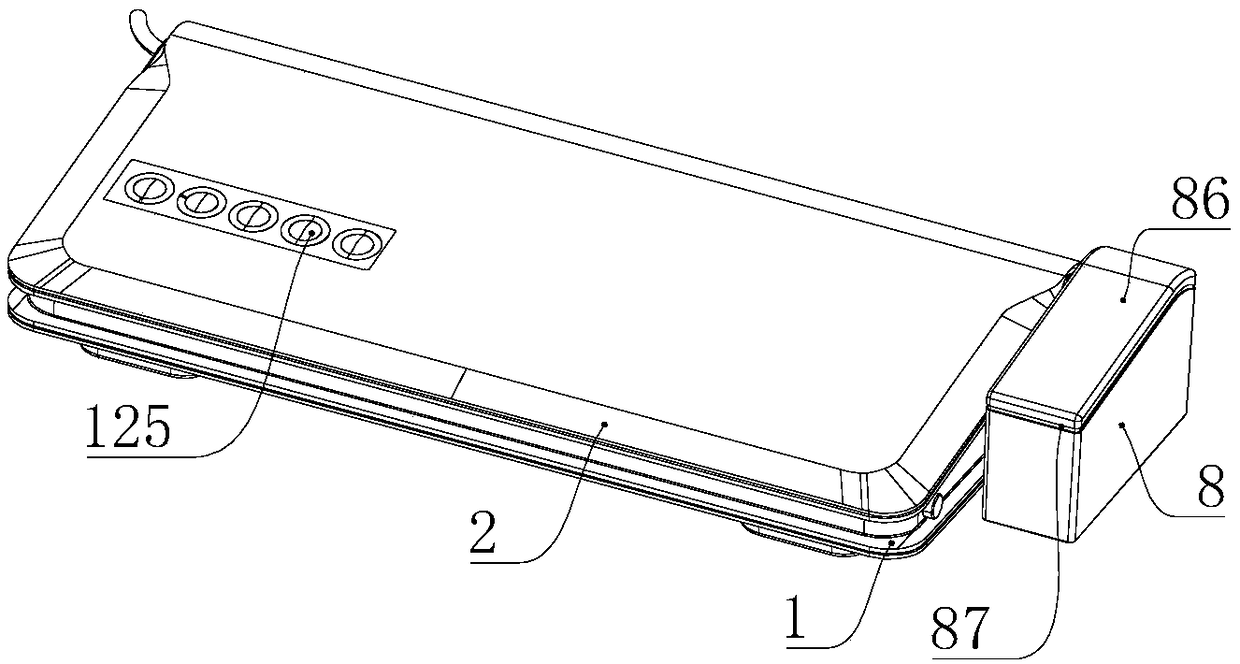

Vacuum sealing machine and sealing method thereof

A vacuum sealing and sealing technology, used in packaging sealing/fastening, external support, transportation packaging, etc., can solve the problems of slow sealing speed, sealing rupture, and long sealing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A sealing method for a vacuum sealing machine, comprising the following steps:

[0057] (1), the vacuum sealing machine is plugged in, and the vacuuming time is set through the control button 125 according to the bags of different thicknesses and materials;

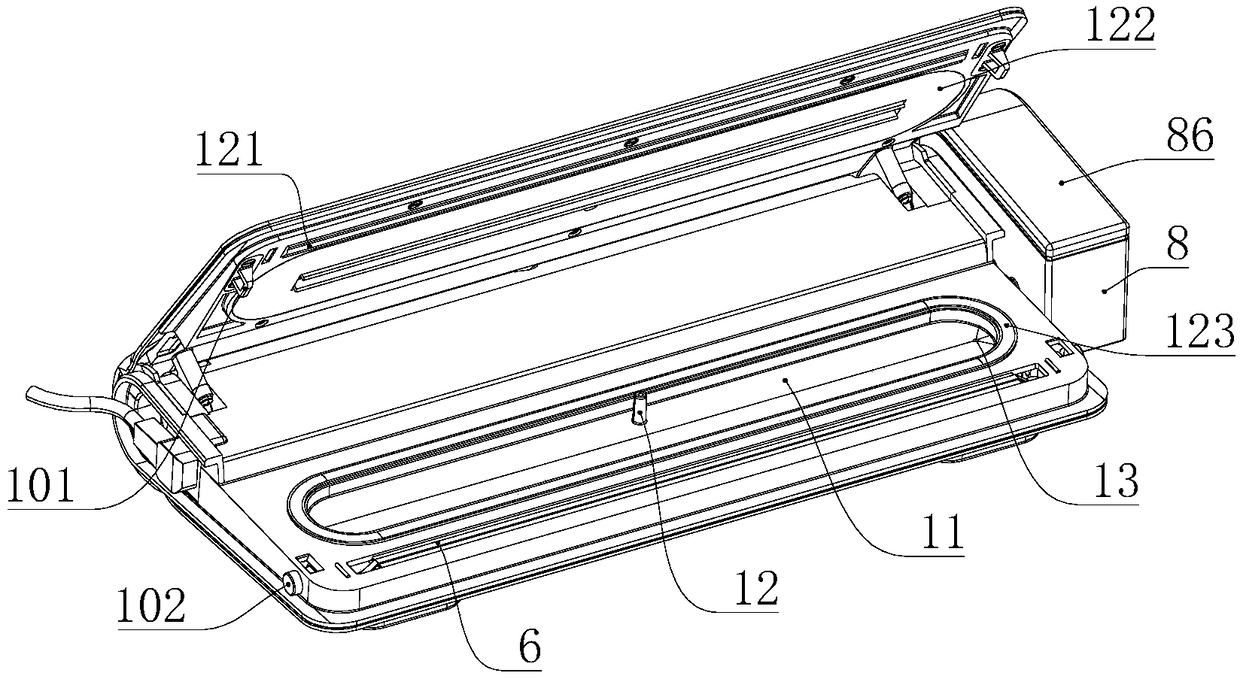

[0058] (2), lift the cover plate, put the mouth of the bag in the concave cavity 11;

[0059] (3), press down the cover plate 2 and lock it through the locking device 10;

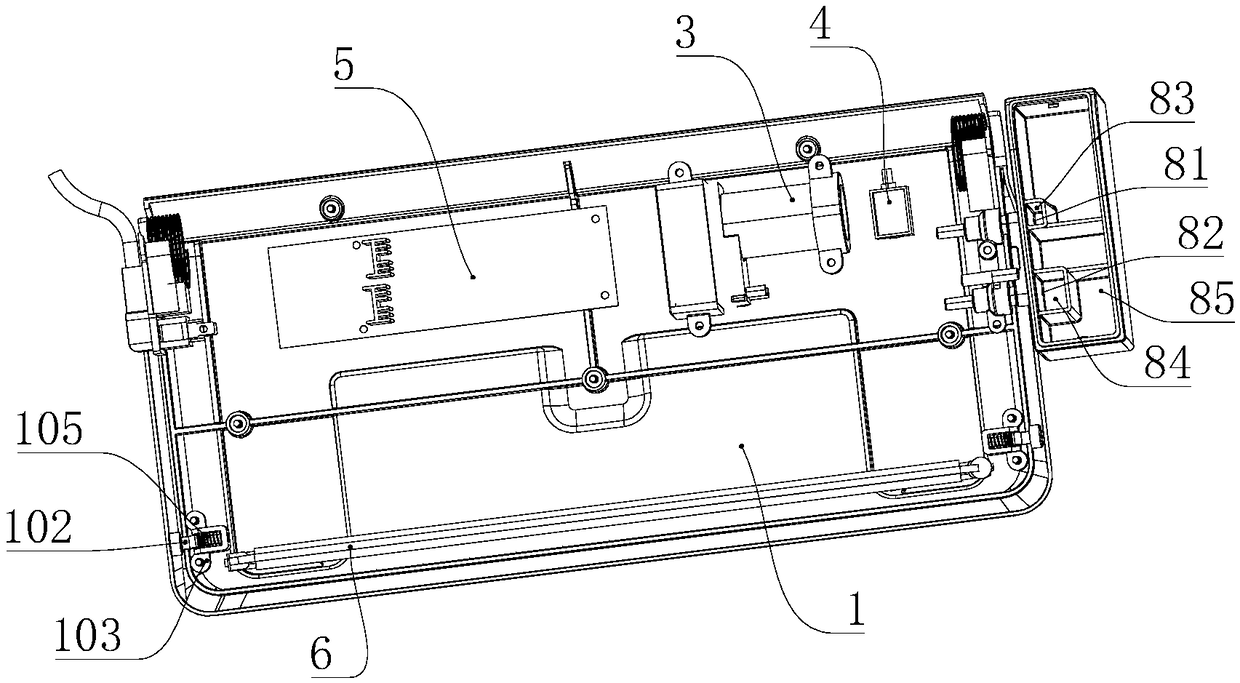

[0060] (4), press the control button 125, the sealing machine automatically pumps air, and the air pressure detector 9 automatically turns off the vacuum pump 3 after detecting the set air pressure;

[0061] (5), then, set the temperature of the temperature sensor 7 by the control button 125 according to the bags of different thicknesses and different materials, press the required control button 125, and the sealing ends;

[0062] (6), release the male buckle 101, lift the cover plate 2, the sealing is completed, and wait for the next sealing....

Embodiment 2

[0064] A sealing method for a vacuum sealing machine, comprising the following steps:

[0065] (1), the vacuum sealing machine is plugged in, and the vacuuming time is set through the control button 125 according to the bags of different thicknesses and materials, and the temperature of the temperature sensor 7 is set through the control button 125 according to the bags of different thicknesses and materials;

[0066] (2), lift the cover, put the mouth of the bag in the concave cavity 11, and place the sealing position in the heating area of the sealing machine, where the heating wire 6 is located;

[0067] (3), press down the cover plate 2 and lock it through the locking device 10;

[0068] (4), press the control button 125, the sealing machine automatically pumps air, and the heating wire 6 heats simultaneously, and the air pressure detector 9 detects the set air pressure and automatically turns off the vacuum pump 3, after the temperature sensor 7 detects the temperature ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap