Cantilever crane of rigid rail

A cantilever crane and rigid technology, which is applied in portable hoisting devices, hoisting devices, cranes, etc., can solve problems such as difficulty in accessing ring chains, inconvenient operation, etc., and achieve the effects of reducing self-weight, reducing consumption, and reducing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

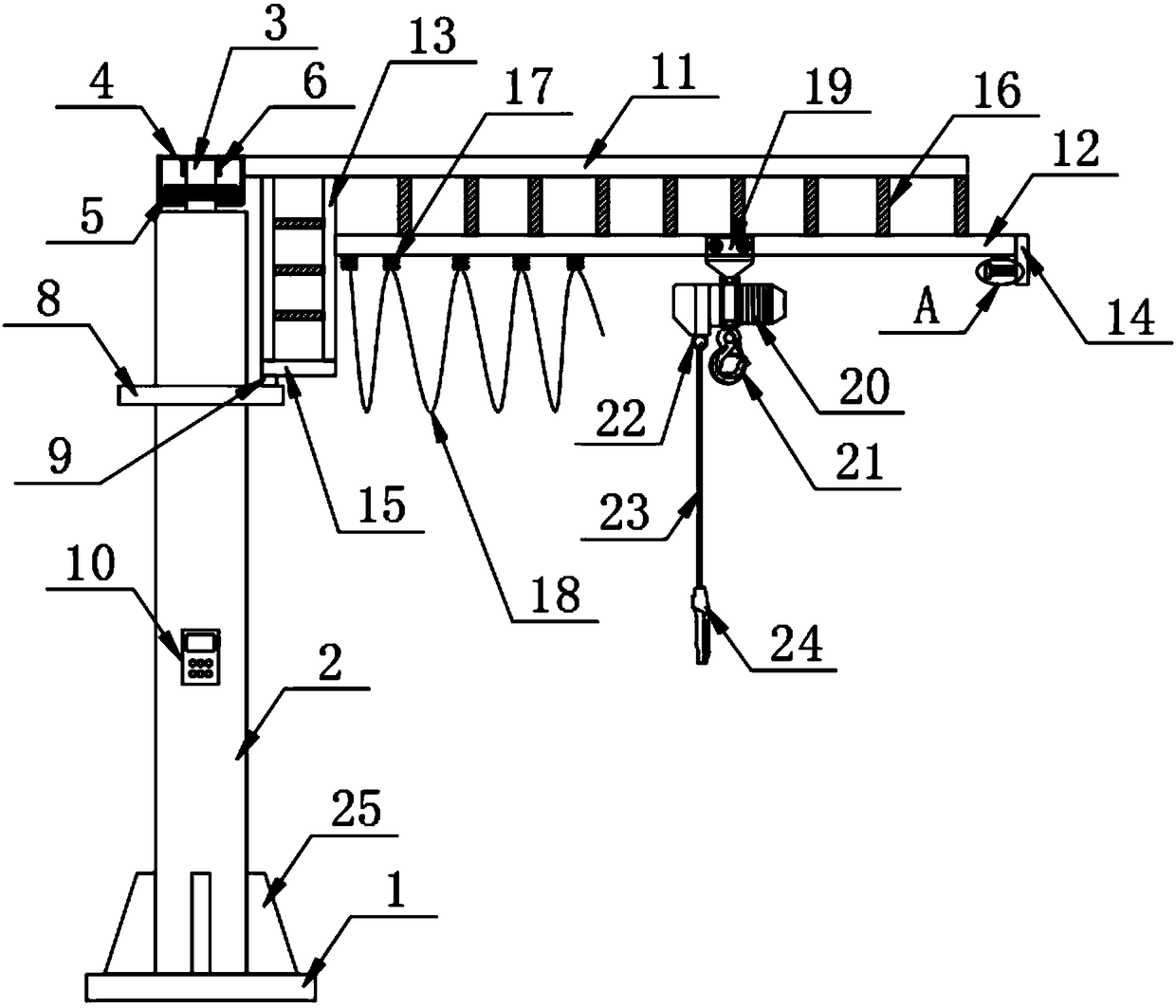

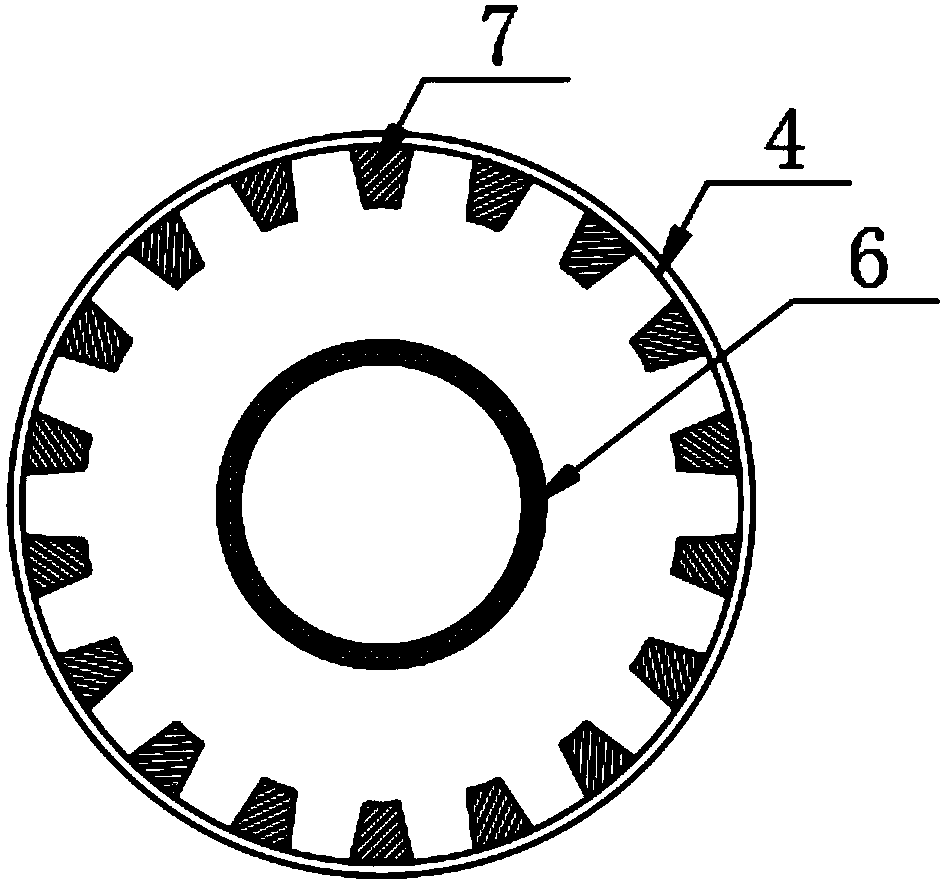

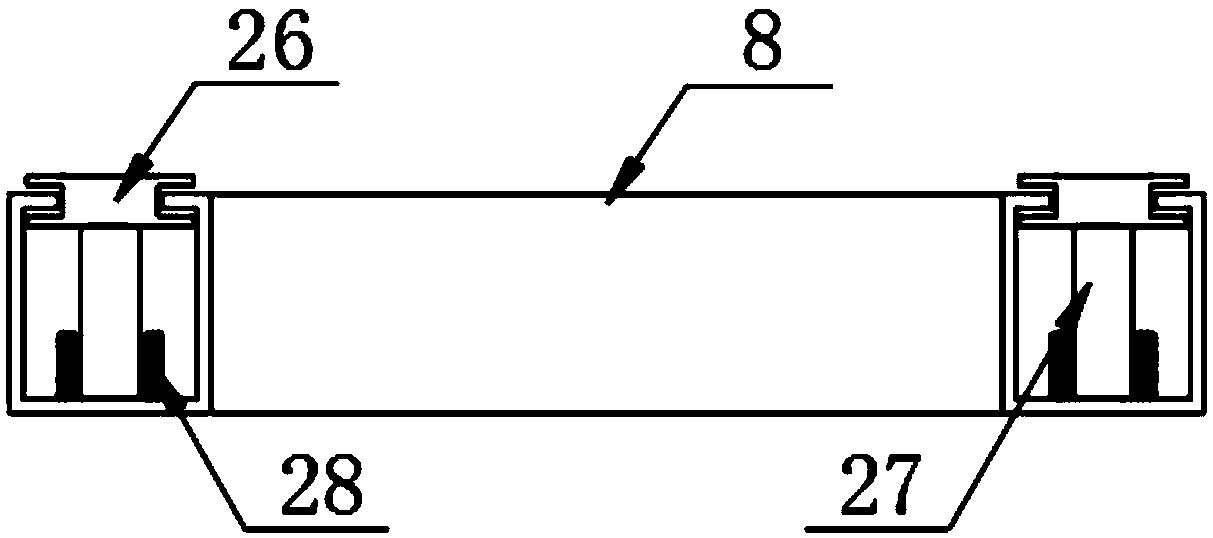

[0024] The present invention provides such as Figure 1-4 A rigid rail cantilever crane shown includes an installation base 1, a column 2 is vertically provided on the top of the installation base 1, and a first guide rod 3 is vertically provided on the top of the column 2, and the first guide rod 3 A first guide cylinder 4 is sheathed on the outside, a second guide cylinder 8 is sleeved on the column 2, a controller 10 is provided on the surface of the column 2, and a cross bar 11 is fixed on one side of the first guide cylinder 4 , the bottom of the cross bar 11 is provided with a guide rail 12, one end of the guide rail 12 is provided with a vertical bar assembly 13 and the other end is provided with a limiting plate 14, the bottom end of the vertical bar assembly 13 is provided with a connecting rod 15, the guide rail 12 A wire fixing clip 17 and an electric trolley 19 are arranged on the top, and a wire 18 is fixed on the wire fixing clip 17. The electric trolley 19 is ar...

Embodiment 2

[0030] Further, in the technical solution of Embodiment 1, the vertical rod assembly 13 is composed of two vertical rods arranged parallel to each other, and a reinforcing rod 16 is fixed between the two vertical rods, and the horizontal rod 11 and the guide rail 12 is also provided with reinforcement rods 16, the number of the number of reinforcement rods 16 is set multiple, can form a plurality of cavities between the two vertical rods and the cross rod 11 and the guide rail 12, so that while ensuring the strength of the cantilever crane itself At the same time, the consumption of materials is reduced, the production cost is saved, and the self-weight of the cantilever crane can be greatly reduced.

[0031] Further, in the technical solution of Example 1, the top of the installation base 1 is welded with a fixed plate 25, and the number of the fixed plates 25 is provided in multiples, and is evenly distributed on the surface of the column 2. The fixed plate 25 and the Weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com