Special low-odor phenol-free barium-zinc stabilizer for toy film and preparation method of barium-zinc stabilizer

A zinc stabilizer, low odor technology, applied in the field of low odor barium phenolate-free zinc stabilizer for toy film and its preparation field, which can solve the problem of "zinc burning", unsatisfactory application effect, poor stabilization effect of calcium zinc heat stabilizer, etc. problem, to achieve the effect of inhibiting zinc burning, improving mechanical and mechanical properties and weather resistance, and improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

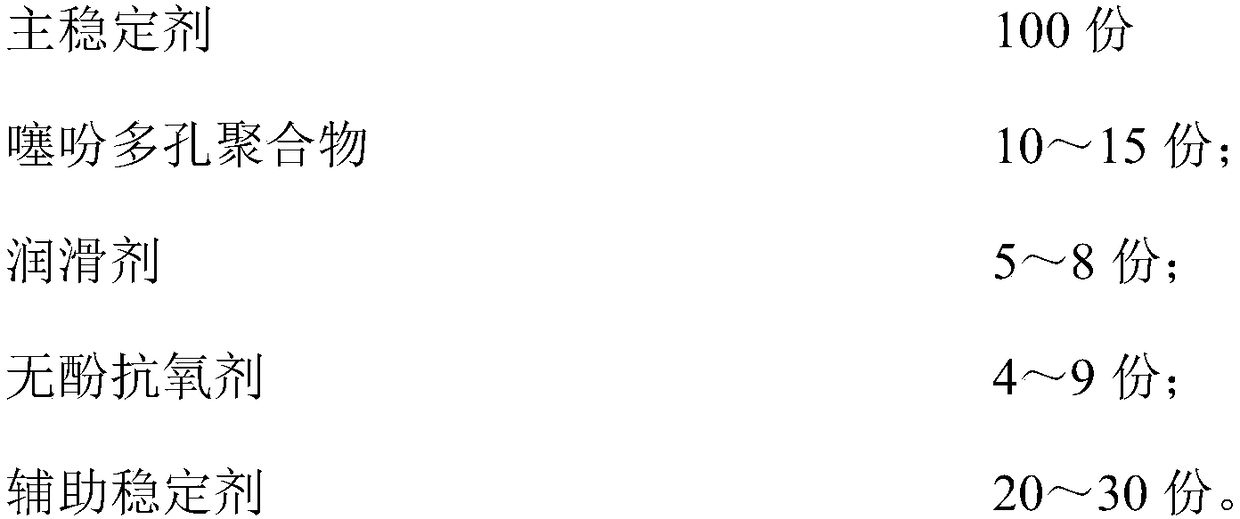

[0027] A special low-odor phenol-free barium-zinc stabilizer for toy films, comprising by weight:

[0028]

[0029] The main stabilizer described above is prepared by the following method:

[0030] Glycerin (purchased from Yangzhou Feiyang Chemical Co., Ltd.) and formic acid (purchased from Shanghai Zhanyun Chemical Co., Ltd.) were added into the stirred reactor at a molar ratio of 1:3, and reacted at normal pressure and 100°C for 10 hours to obtain glycerol formate; Add calcium oxide (purchased from Suzhou Bosheng Industry and Trade Co., Ltd.) and zinc oxide (purchased from Seoul International Trade (Shanghai) Co., Ltd.) that are equimolar to glycerin into glycerol formate and react at normal pressure and 160°C for 5 hours , lower the temperature to 100°C, add triglycidyl isocyanurate (purchased from Suzhou Fulu Biotechnology Co., Ltd.) with a molar ratio of 0.1:1 to glycerol, and continue the reaction for 1 hour. The obtained product is dried and crushed and passed throug...

Embodiment 2

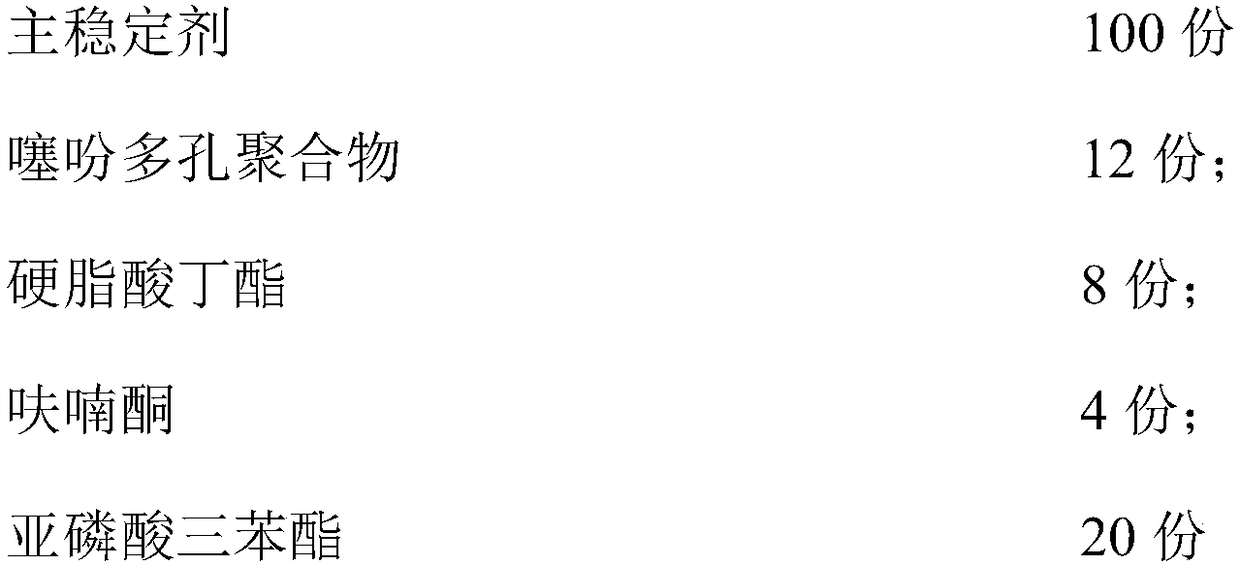

[0037] A special low-odor phenol-free barium-zinc stabilizer for toy films, comprising by weight:

[0038]

[0039] The main stabilizer described above is prepared by the following method:

[0040] Glycerin (purchased from Yangzhou Feiyang Chemical Co., Ltd.) and acetic acid (purchased from Shanghai Zhanyun Chemical Co., Ltd.) were added into the stirred reactor at a molar ratio of 1:1, and reacted at normal pressure and 110°C for 8 hours to obtain glycerol acetate; Add calcium oxide (purchased from Suzhou Bosheng Industry and Trade Co., Ltd.) and zinc oxide (purchased from Shouli International Trade (Shanghai) Co., Ltd.), which are equimolar to glycerin, into glycerol acetate and react at normal pressure and 160°C for 5 hours. , lower the temperature to 100°C, add triglycidyl isocyanurate (purchased from Suzhou Fulu Biotechnology Co., Ltd.) with a molar ratio of 0.3:1 to glycerin, and continue the reaction for 2 hours. The obtained product is dried and crushed and passed t...

Embodiment 3

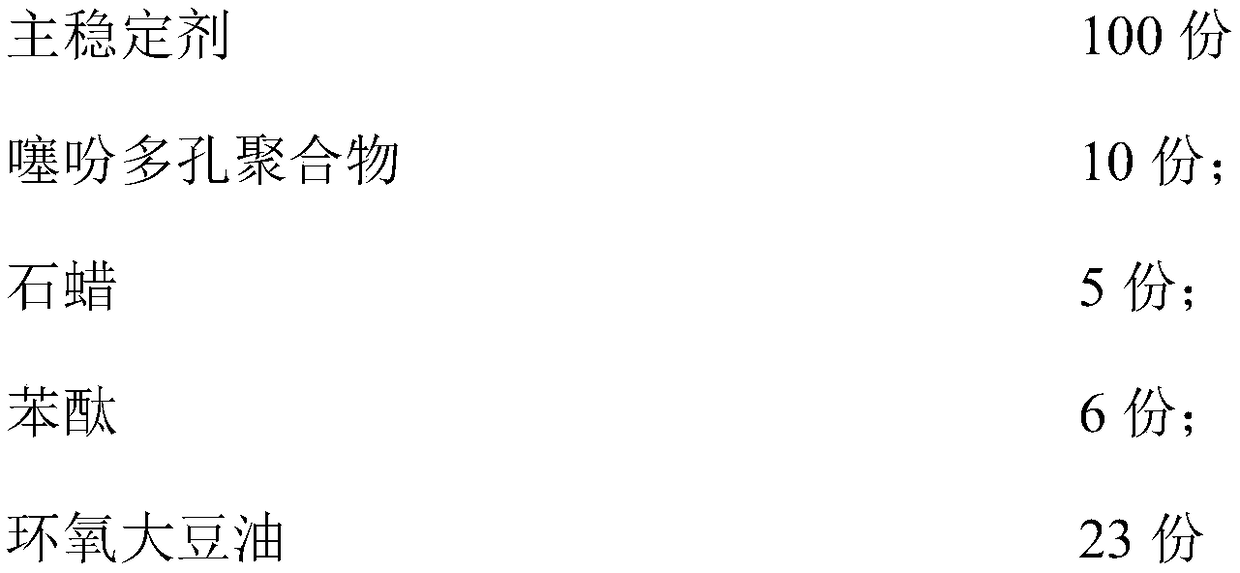

[0047] A special low-odor phenol-free barium-zinc stabilizer for toy films, comprising by weight:

[0048]

[0049]

[0050] The main stabilizer described above is prepared by the following method:

[0051] Add glycerin (purchased from Yangzhou Feiyang Chemical Co., Ltd.) and glutaconic acid (purchased from Hubei Jusheng Technology Co., Ltd.) into the stirred reactor at a molar ratio of 1:5, and react at normal pressure and 120°C for 6 hours to obtain glycerol pentene Diacyl ester; Calcium oxide (purchased from Suzhou Bosheng Industry and Trade Co., Ltd.) and zinc oxide (purchased from Shouli International Trade (Shanghai) Co., Ltd.) equimolar with glycerol were added to glycerol glutaric acid ester in normal Pressed at 170°C for 4 hours, cooled to 100°C, added triglycidyl isocyanurate (purchased from Suzhou Fulu Biotechnology Co., Ltd.) with a molar ratio of 0.5:1 to glycerin, and continued to react for 1 hour. The obtained product was dried, After crushing, pass throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap