Sliding member and production method therefor

A sliding member, manufacturing method technology, applied in the direction of anti-centrifugal rotating parts, bearing components, mechanical equipment, etc., can solve the problems of loss of lubrication, worry about durability, price increase, etc., achieve burn inhibition, reduce friction, and improve activity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1、1-2

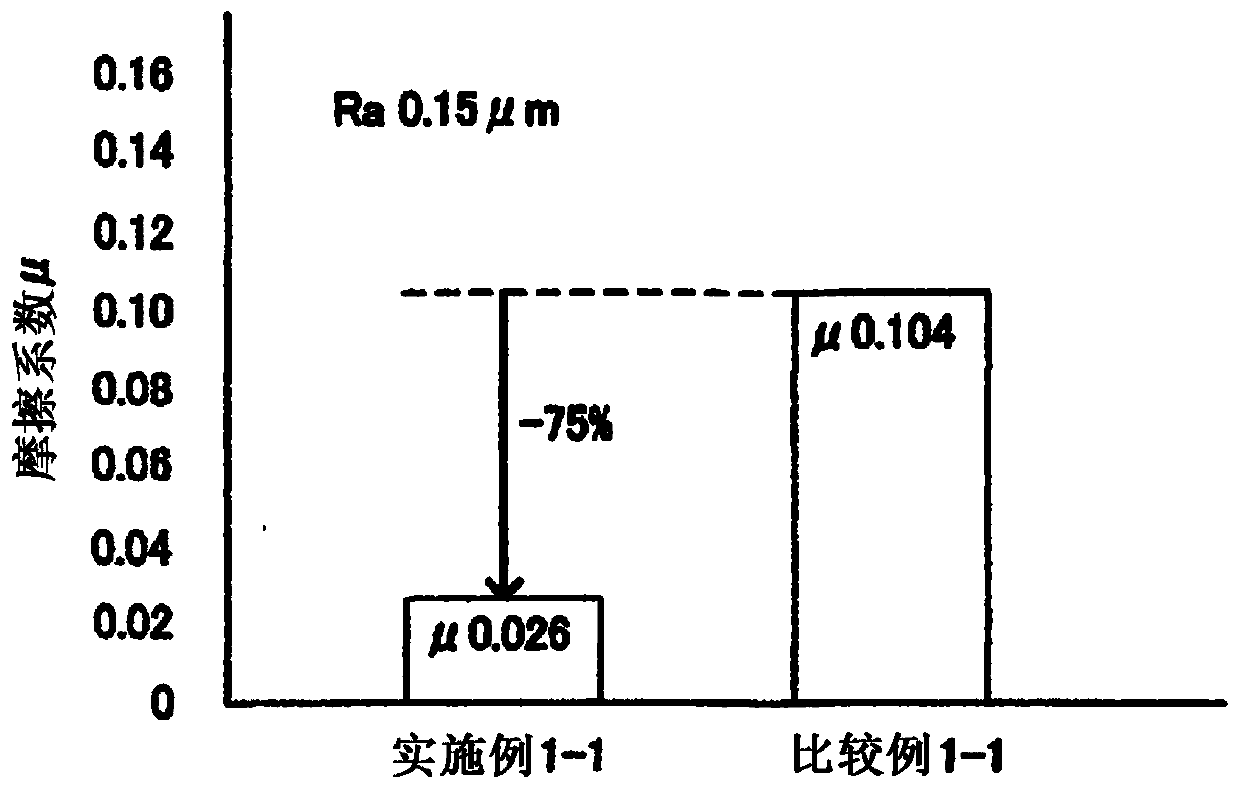

[0049] (Example 1-1, 1-2, Comparative Example 1-1, 1-2)

[0050] As Examples 1-1 and 1-2, disc-shaped test pieces made of bearing steel (SUJ2) were prepared, and wet shot blasting was performed using a shot material containing 15% by mass to 30% by mass of Cr. At this time, the surface roughness Ra was adjusted by changing the air pressure, and the surface roughness Ra of Example 1-1 was set to 0.15 μm, and the surface roughness Ra of Example 1-2 was set to 0.3 μm. A ball-on-disc friction test was performed on the shot-peened test piece in MoDTC lubricating oil containing 200 ppm of the Mo component. The counterpart material is bearing steel (SUJ2). The temperature of the lubricating oil was kept constant at 80° C., the load was 10 N, and the sliding speed was 0.5 m / s, and the friction coefficient after stabilization was measured.

[0051] As Comparative Examples 1-1 and 1-2, the same test pieces as in Examples 1-1 and 1-2 were prepared, except that the projection material w...

Embodiment 2

[0056] In the same manner as in Examples 1-1 and 1-2, the test piece was shot-peened, and the coefficient of friction was measured. At this time, the surface roughness Ra was adjusted by changing the conditions by changing the air pressure to 0.05 MPa to 0.5 MPa, and the relationship between the surface roughness Ra and the coefficient of friction was investigated. The result obtained is as Figure 6 shown. Such as Figure 6 As shown, it can be seen that it is preferable to set the surface roughness Ra within the range of 0.03 μm to 0.4 μm, and it is more preferable to set it within the range of 0.04 μm to 0.3 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap