Special-shaped energy dissipation caisson and breakwater

A technology of energy dissipation and caisson, which is applied in coastal engineering and port fields, can solve the problems of increased wave force of caisson, poor wave dissipation effect, and easy scour of seabed, so as to reduce wave energy, improve free exchange capacity, and reduce structural stress. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

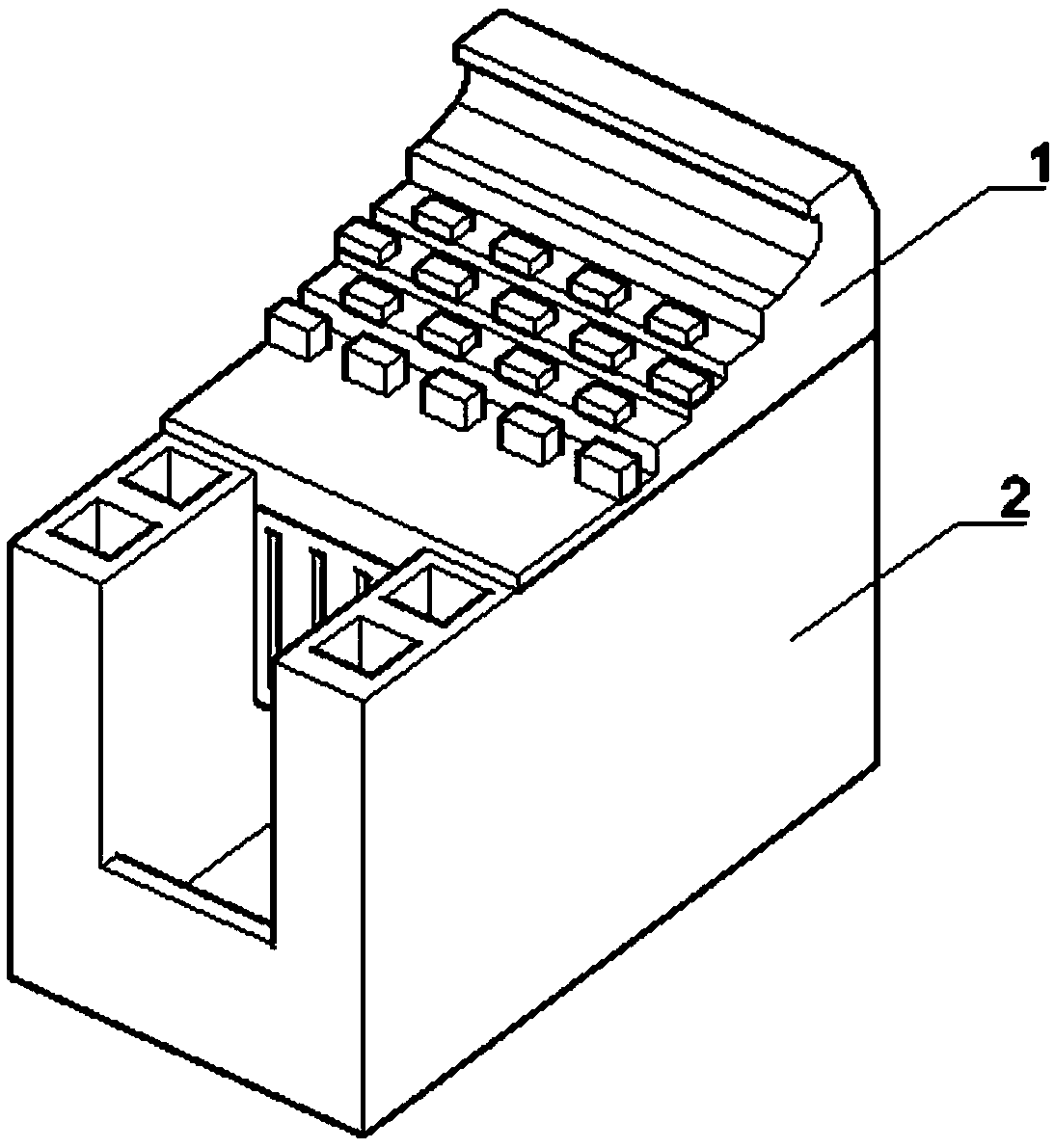

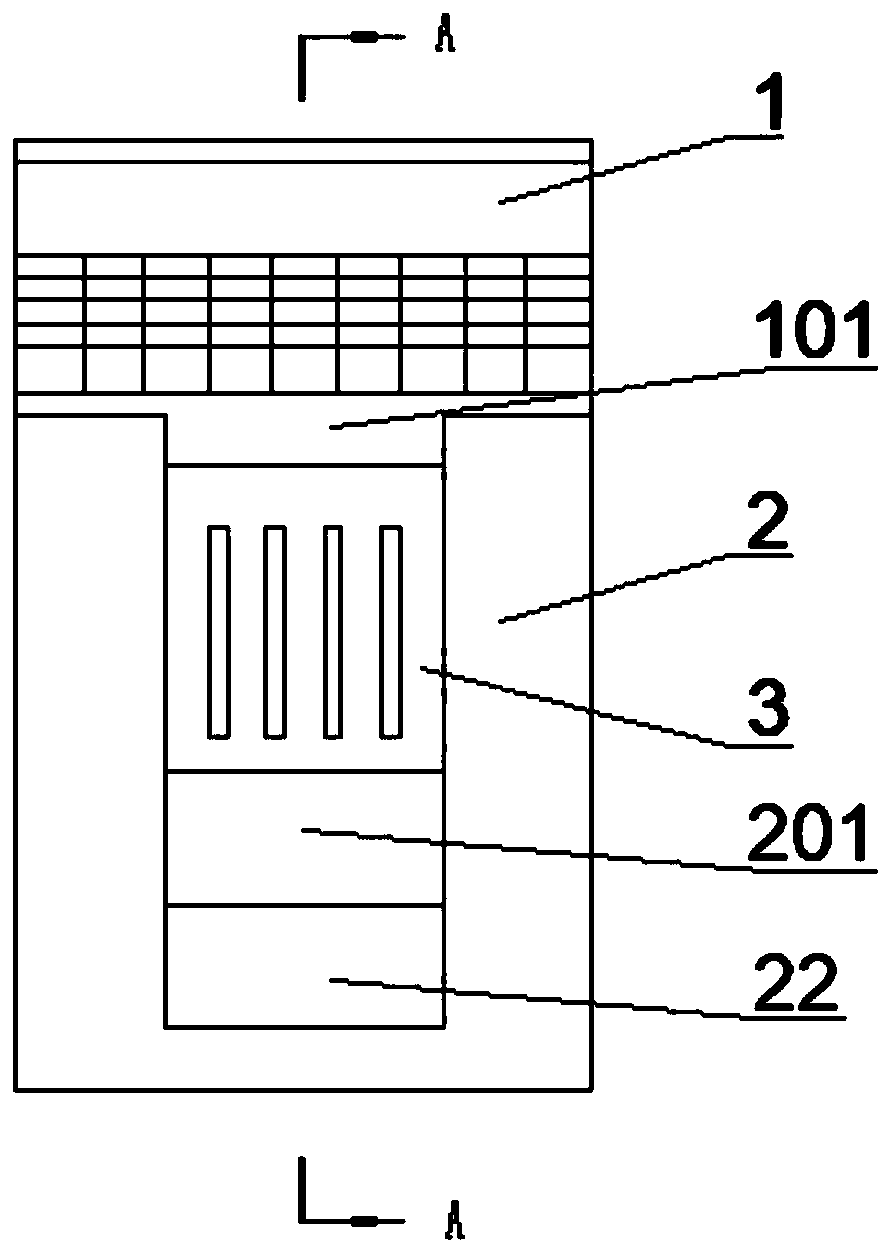

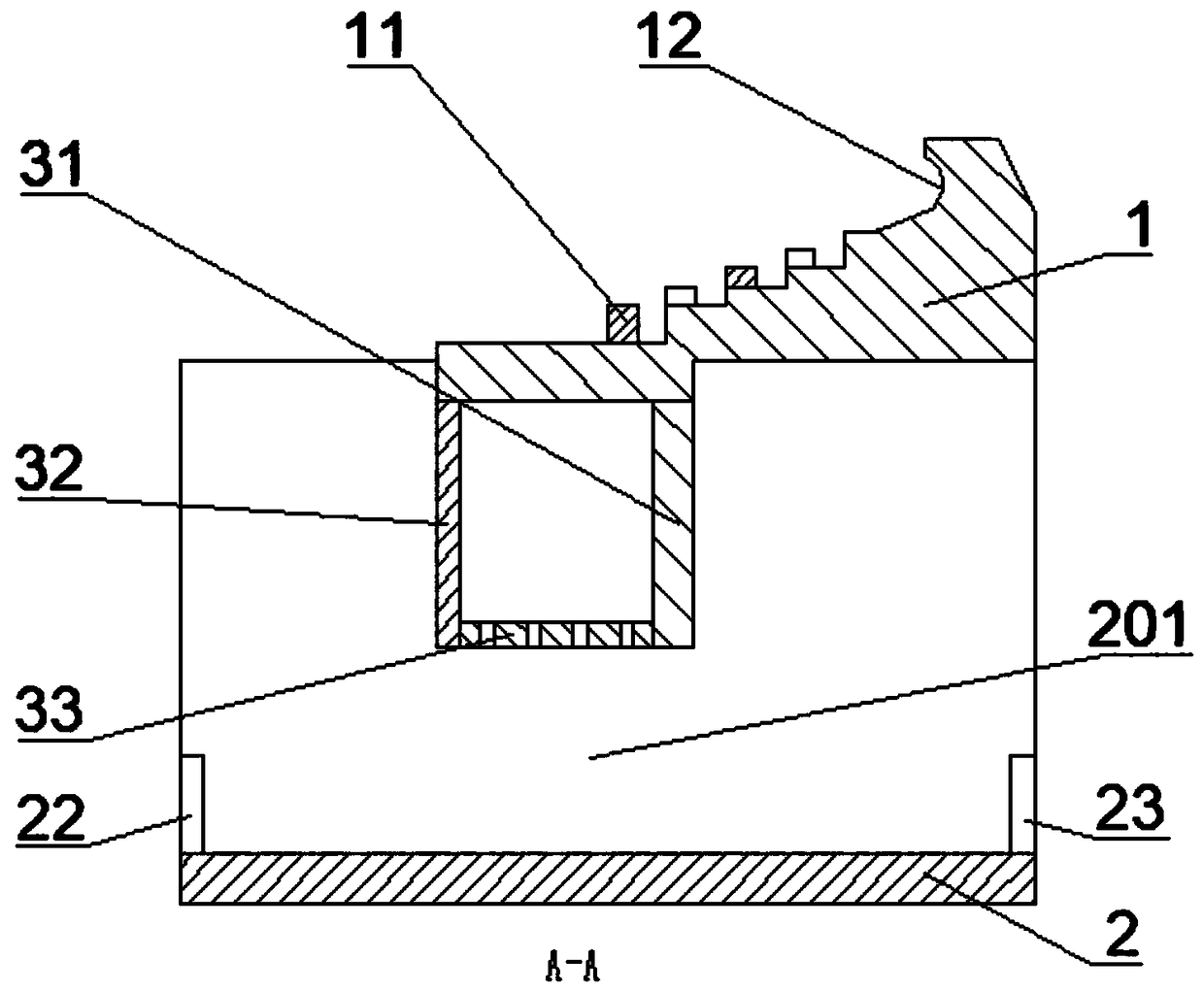

[0035] Such as figure 1 As shown, different from the existing square caisson, the special-shaped energy-dissipating caisson of this embodiment includes a box body 2, and the side of the box body 2 is suitable for assembling the structure to be assembled. Such as figure 2 As shown, the front side shown is the wave-facing side of the special-shaped energy-dissipating caisson, that is, the front side. The box body 2 includes a left wall, a right wall and a bottom wall. The left and right walls of the box body 2, that is, the two side walls, reserve a through-hole area running through the front and back.

[0036] The upper surface of the bottom wall is below the hollow area, and the lower surface of the fixing block 101 is above the hollow area. In this embodiment, the hollow area is a straight hole, but it may actually have a certain bend. Before actual manufacturing, the hydrological data of the place of use should be referred to, and the overall stability of the structure ...

Embodiment 2

[0055] Such as Figure 8 As shown, multiple embodiments 1 are arranged side by side to form a breakwater, and the compartment 21 is filled with gravel as a counterweight. The breast wall 1 on the upper part is integrally cast on site, and the bottom surface is joined with the top surface of the box body 2 .

Embodiment 3

[0057] The front of the box 2 is a U-shape, including a bottom wall and two caissons. When multiple U-shaped boxes 2 are juxtaposed, the sides of the adjacent caissons are attached, and the fit between the caissons makes the overall stability of the structure better. Wherein the strip-shaped holes of the vertical perforated plate 32 are horizontal, and the strip-shaped holes of the horizontal perforated plate 33 are longitudinal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com