Movable pipeline support for building construction and using method thereof

A kind of building construction and mobile technology, applied in the direction of buildings, building types, towers, etc., can solve the problems of being easily trampled, squeezed, unprotected, messy layout, etc., to facilitate transportation and circulation, and reduce damage. The probability of , the effect of easy to expand and collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

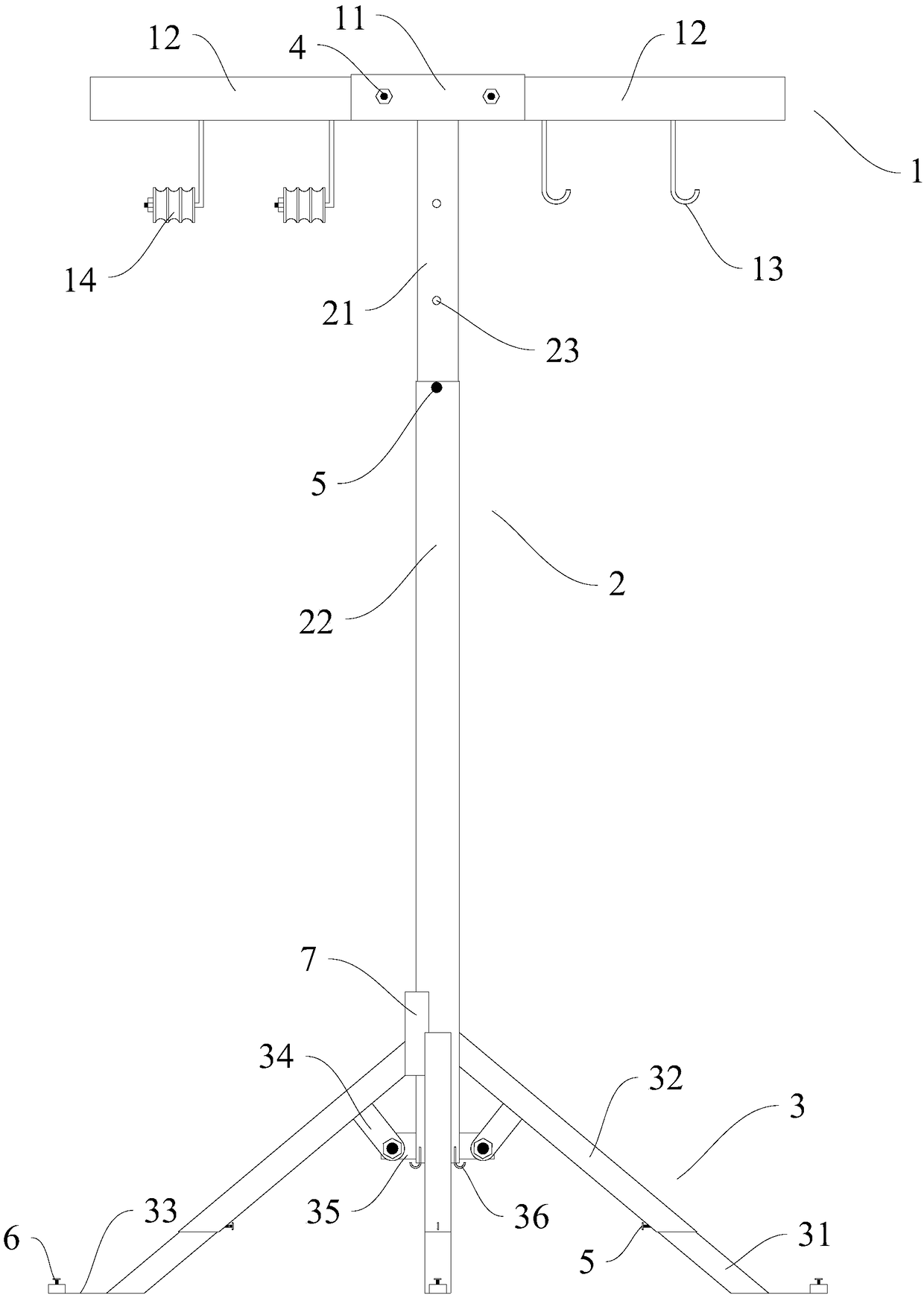

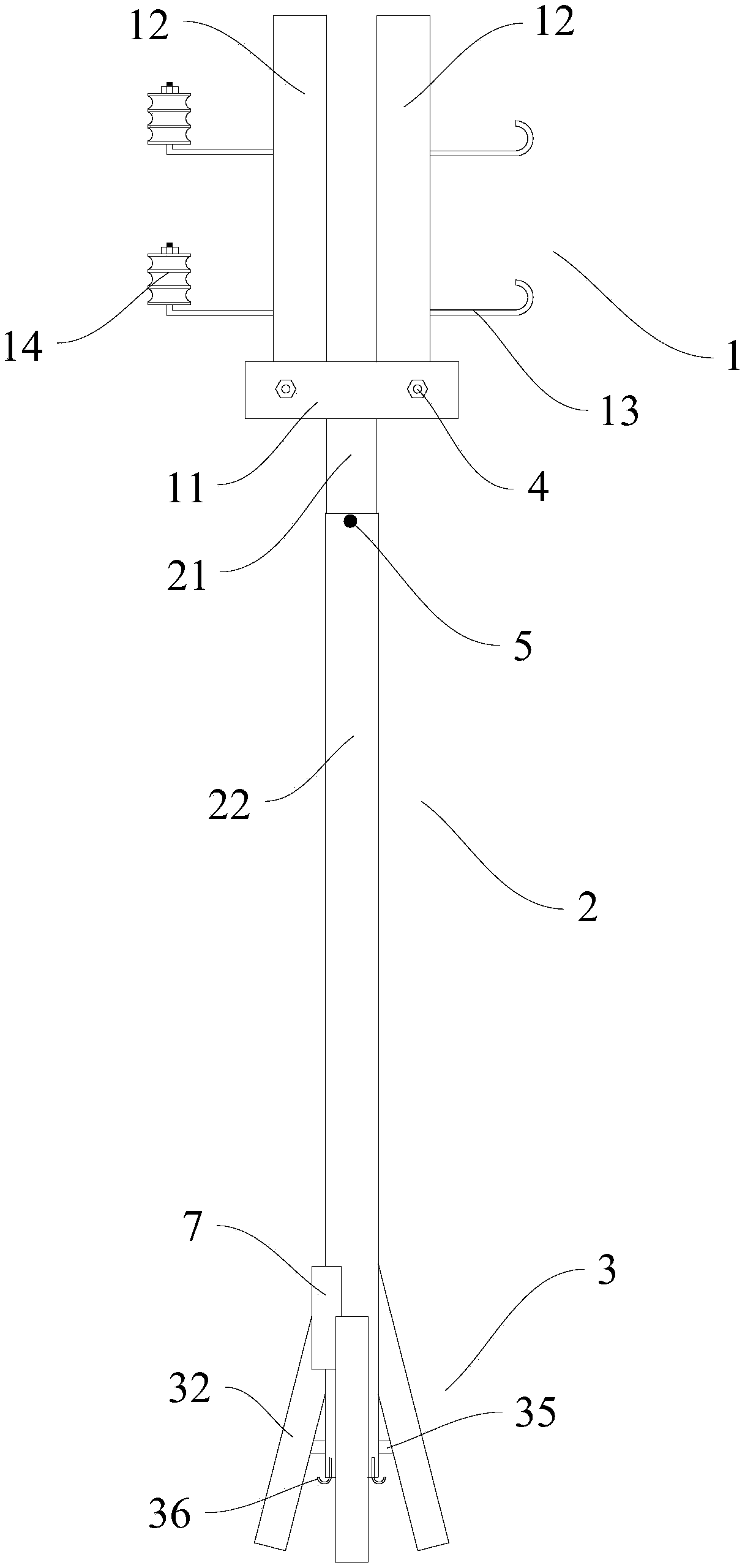

[0052] Such as Figure 1-Figure 2 As shown, a mobile pipeline support for building construction includes a foldable upper cross bar 1 , an adjustable column 2 and a foldable support foot 3 . in,

[0053] The foldable upper crossbar 1 includes a joist 11, the joist 11 adopts a channel steel structure, two ends of the joist 11 are hinged with two foldable rods 12, and the foldable rods 12 are connected by pins 4 fixed on the joist 11. Two installation hooks 13 are detachably mounted on one of the foldable rods 12 , and two hollow insulating rubber supporting wheels 14 are detachably mounted on the other foldable rod 12 .

[0054] The adjustable column 2 includes a telescopic tube 21 fixed on the lower part of the joist 11, and a sleeve 22 sleeved outside the telescopic tube 21, and the telescopic tube 21 can slide relative to the sleeve 22 to To achieve elongation or shortening, the adjustable height is about 40cm-80cm. Specifically, several mounting holes 23 are provided on...

Embodiment 2

[0060] A method for using a mobile pipeline support for building construction, comprising the following steps:

[0061] a: Expand the bracket

[0062] a1: extend the telescopic rod 31 from the sleeve rod 32, adjust the length of the telescopic rod 31, and fix it by tightening the bolt 5; adjust the sleeve rod 32 and the sleeve by turning the bolt 34 22 until the angle between the sleeve rod 32 and the sleeve 22 is about 45°;

[0063] a2: unfold the stable foot plate 33, and fix one end of the stable foot plate 33 on the ground through the bolt 6;

[0064] a3: unfolding the foldable rod 12;

[0065] a4: adjust the telescopic tube 21 up, and fix it on the casing 22 by tightening the bolt 5;

[0066] a5: place the cable pipeline on the installation hook 13 or the hollow insulating rubber supporting wheel 14;

[0067] b: Fold the stand

[0068] b1: Recover the cable pipeline at the installation hook 13 or the hollow insulating rubber supporting wheel 14;

[0069] b2: pull ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com