Hand-operated locking mechanism

A manual locking and handle technology, applied in building structures, building fastening devices, and wing fan fastening devices, etc., can solve problems such as affecting user power transmission, affecting operation time, and long opening time, which is not easy to achieve. The effect of failure and loosening, simple structure, convenient opening and locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

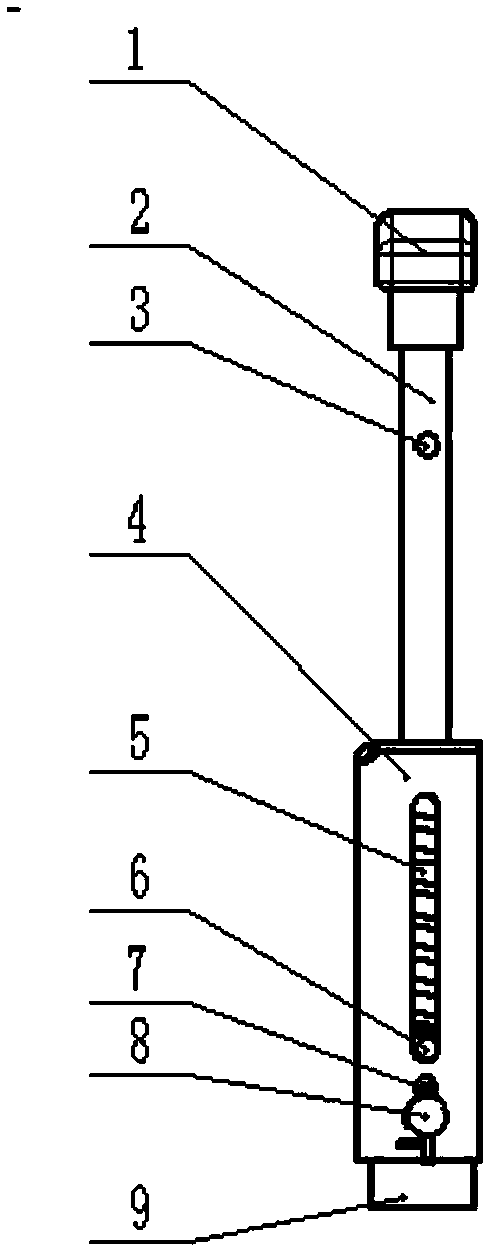

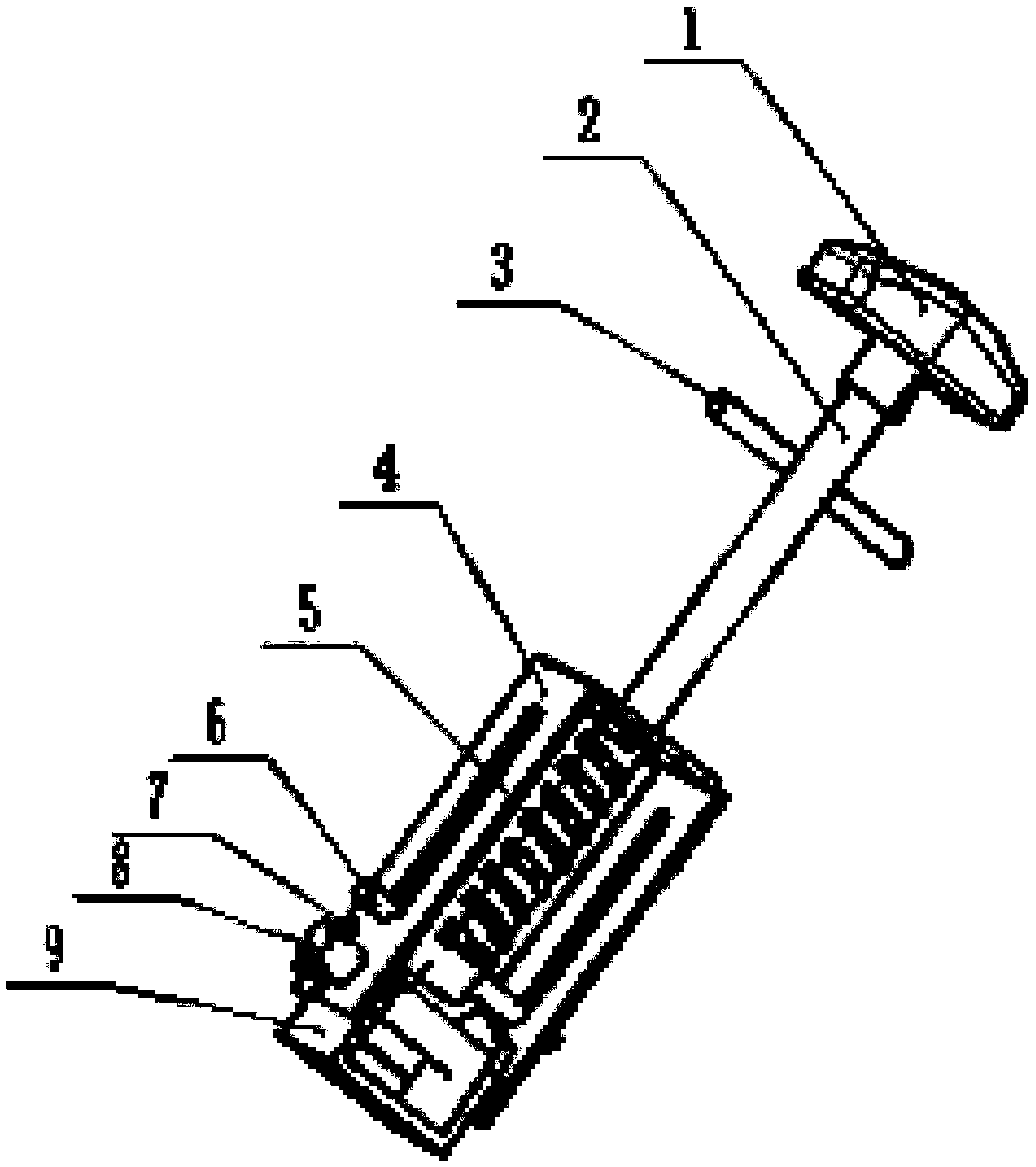

[0019] The present invention will be described in detail below in conjunction with accompanying drawing, as figure 1 , 2 , 3 shows: the present embodiment includes the handle 1 inlaid on the cylinder 2, the upper and lower positions of the cylinder 2 respectively have an upper stop pin 3 and a lower stop pin 6, and the cylinder 2 passes through the guide rail bracket 4 The round hole of the plane is inserted into the spring 5 again, and the lower stop pin 6 penetrates into the cylinder 2 and is in the oblong hole on the side plane of the guide rail bracket 4; there is a fixed bracket 9 below the guide rail bracket 4, and the pin shaft 8 passes through it. Through the holes of the guide rail bracket 4 and the fixed bracket 9, use the cotter pin 7 to penetrate the 8 holes of the pin shaft and lock it; by pulling the handle 1, the linkage cylinder 2 moves up and down in the direction of the oblong hole of the guide rail bracket to lock.

[0020] The handle 1 is made of rubber ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com