Fingerprint module station height measuring mechanism and station height measuring method

A fingerprint module and measuring mechanism technology, applied to measuring devices, instruments, etc., can solve the problems of small lifting and driving impact force, easy generation of lateral force, machining errors of mechanical parts, etc., achieving simple and practical structure, convenient production and installation, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

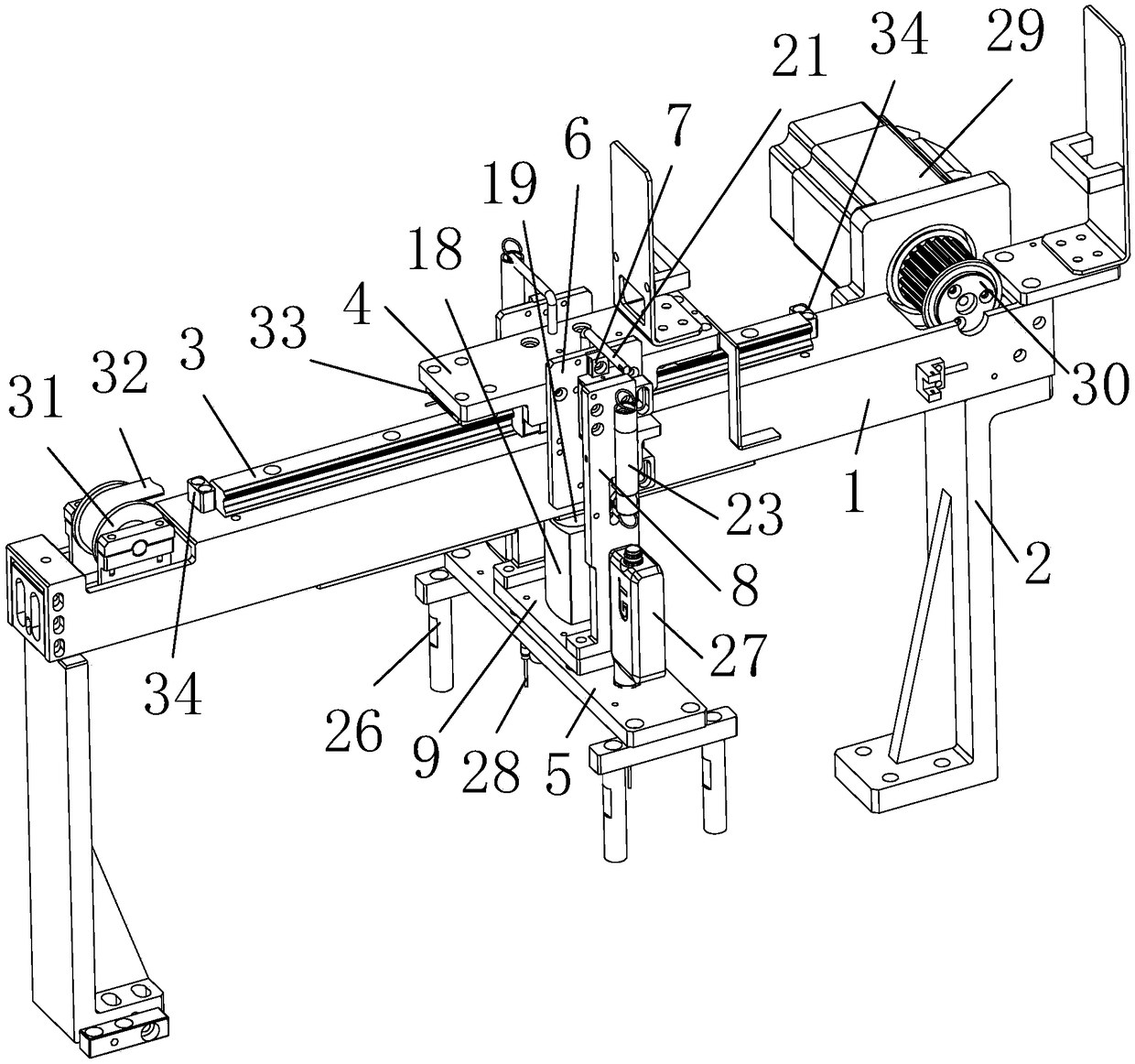

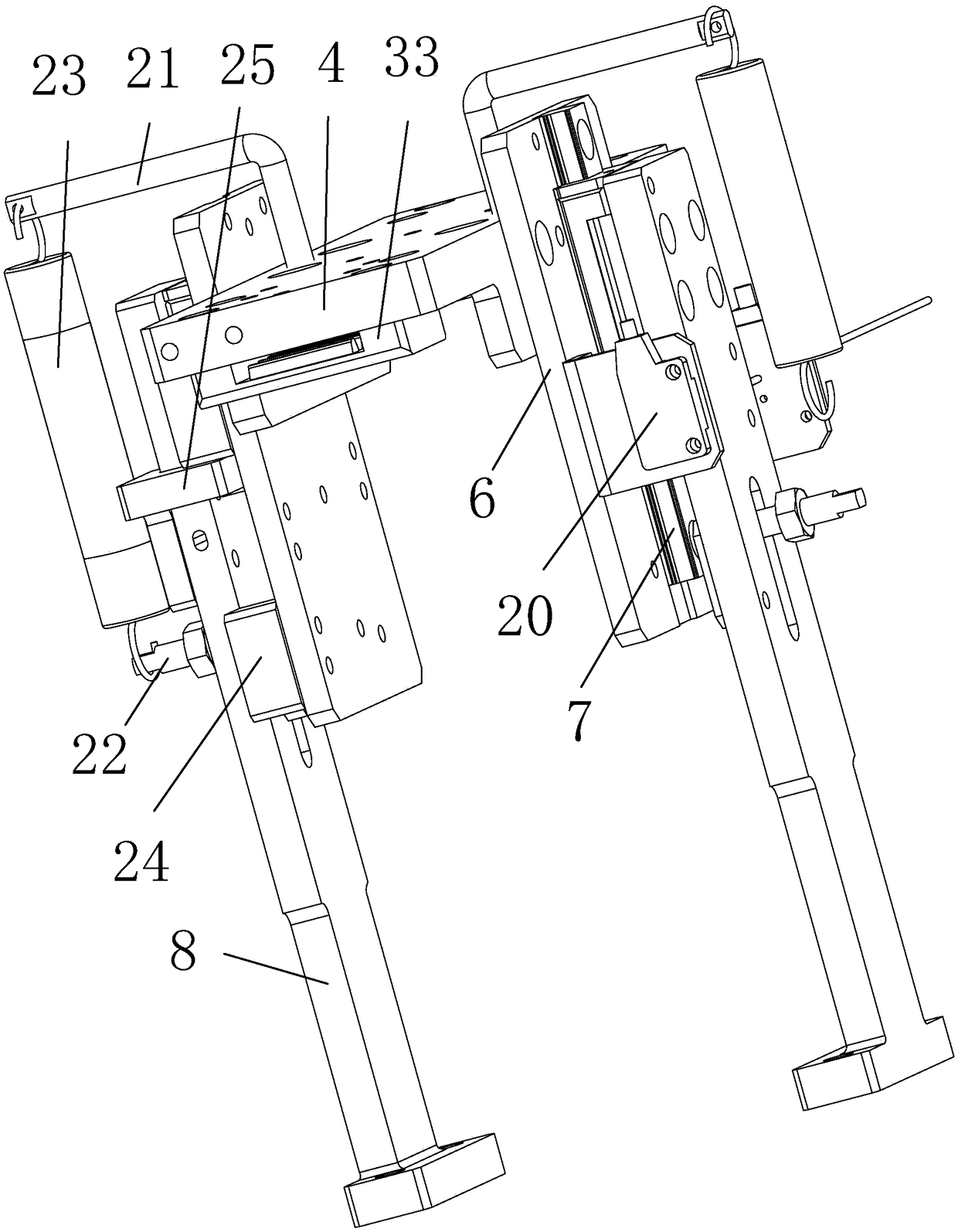

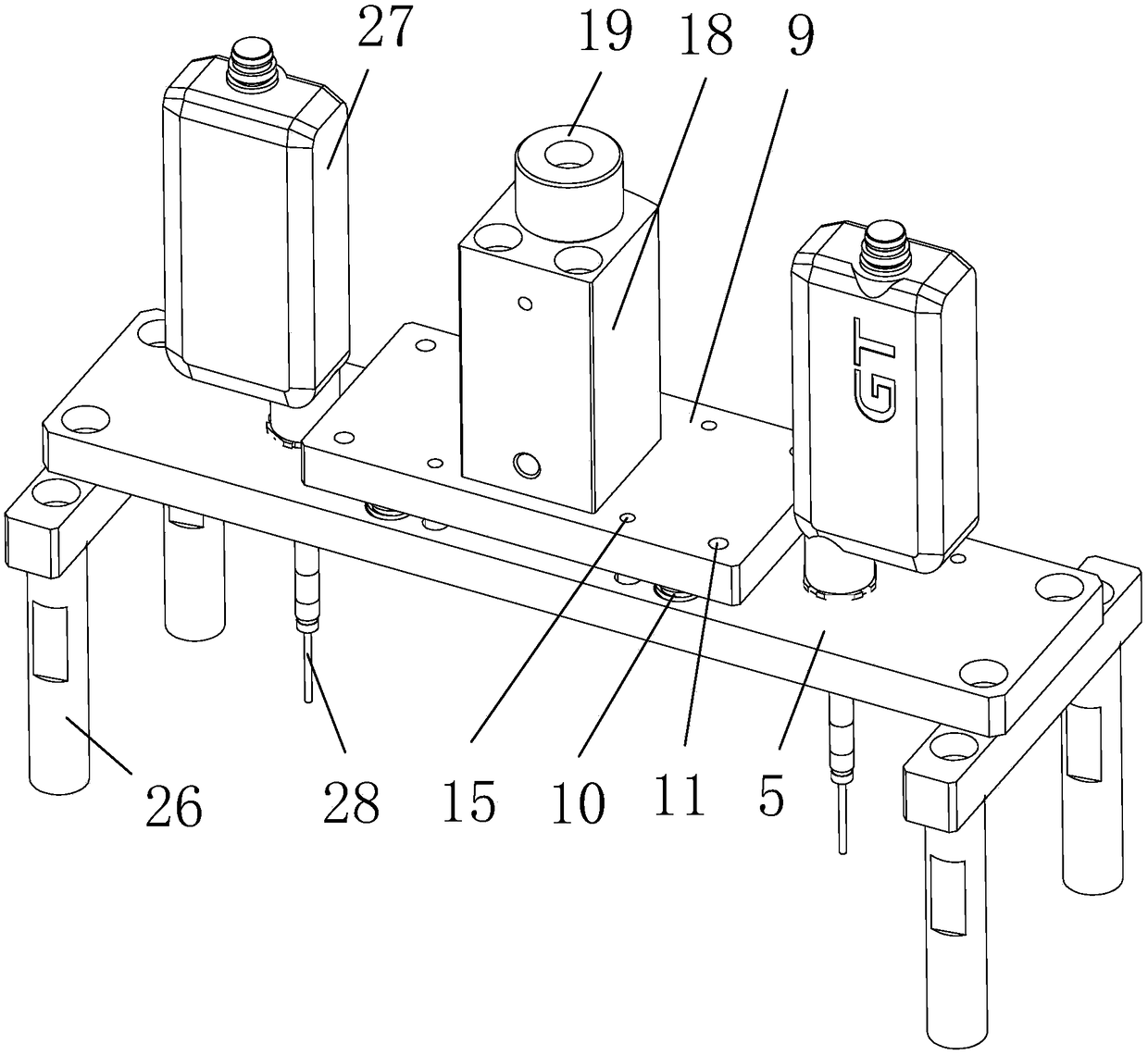

[0018] as attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 Shown: a fingerprint module station height measurement mechanism, including: a bracket 2 provided with a beam 1, a moving linear guide rail 3 arranged on the upper end of the beam 1, a moving seat 4 screwed to the slider of the moving linear guide rail 3, and moving Driving device, two lifting assemblies corresponding to the two sides of the mobile seat 4 one by one, are provided with a station height measuring device positioned at the mounting seat 5 on the lower side of the lifting assembly, and a lifting device; The connected base plate 6 is connected to the lifting plate 8 slidingly connected with the base plate 6 through the vertical linear guide rail 7; a floating assembly is arranged between the lower end of the lifting plate 8 and the mounting seat 5.

[0019] The floa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com