Intelligent-classifying dry and wet garbage barrel

A trash can, dry and wet technology, applied in the direction of trash cans, garbage collection, household appliances, etc., can solve the problems of kitchen pollution, easy overflow, pollution of dry garbage, etc., achieve simple mechanism structure, avoid fermentation and stink, automation high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

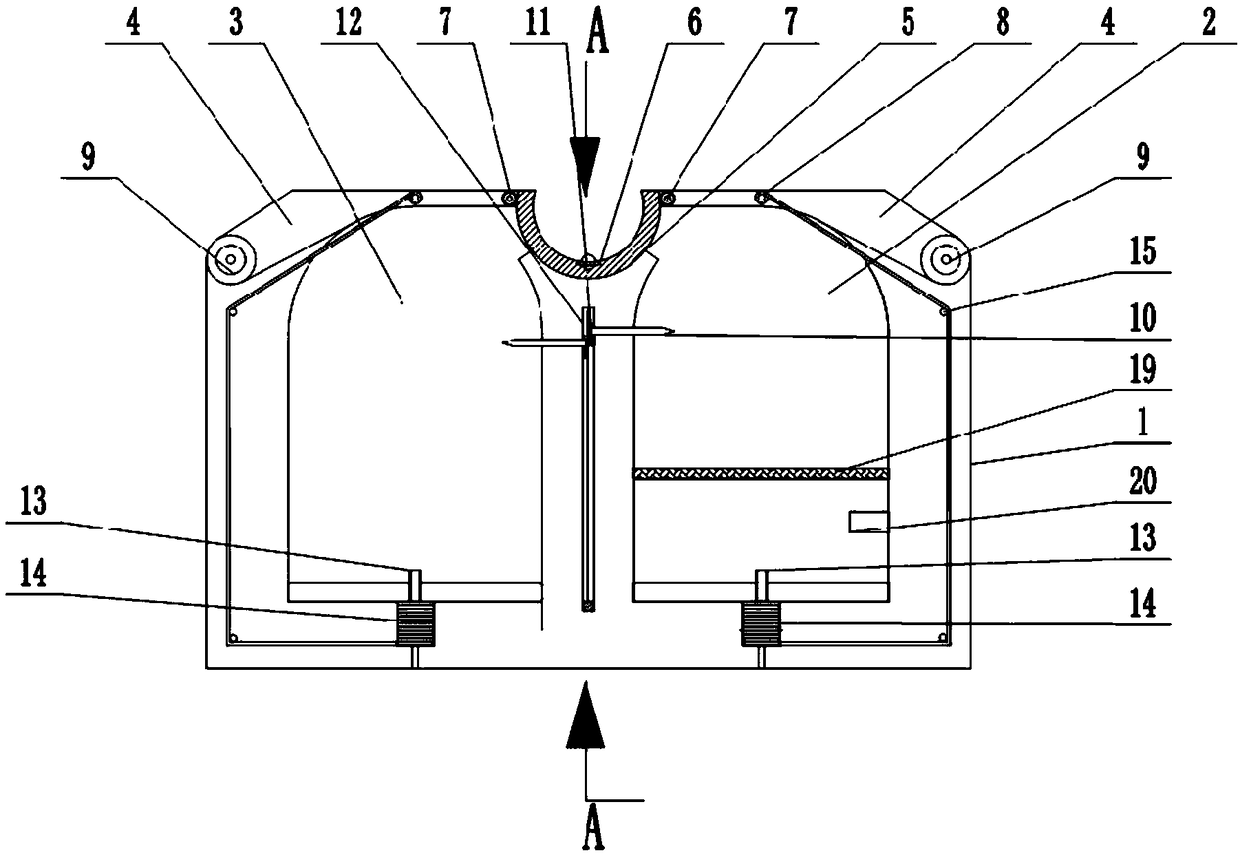

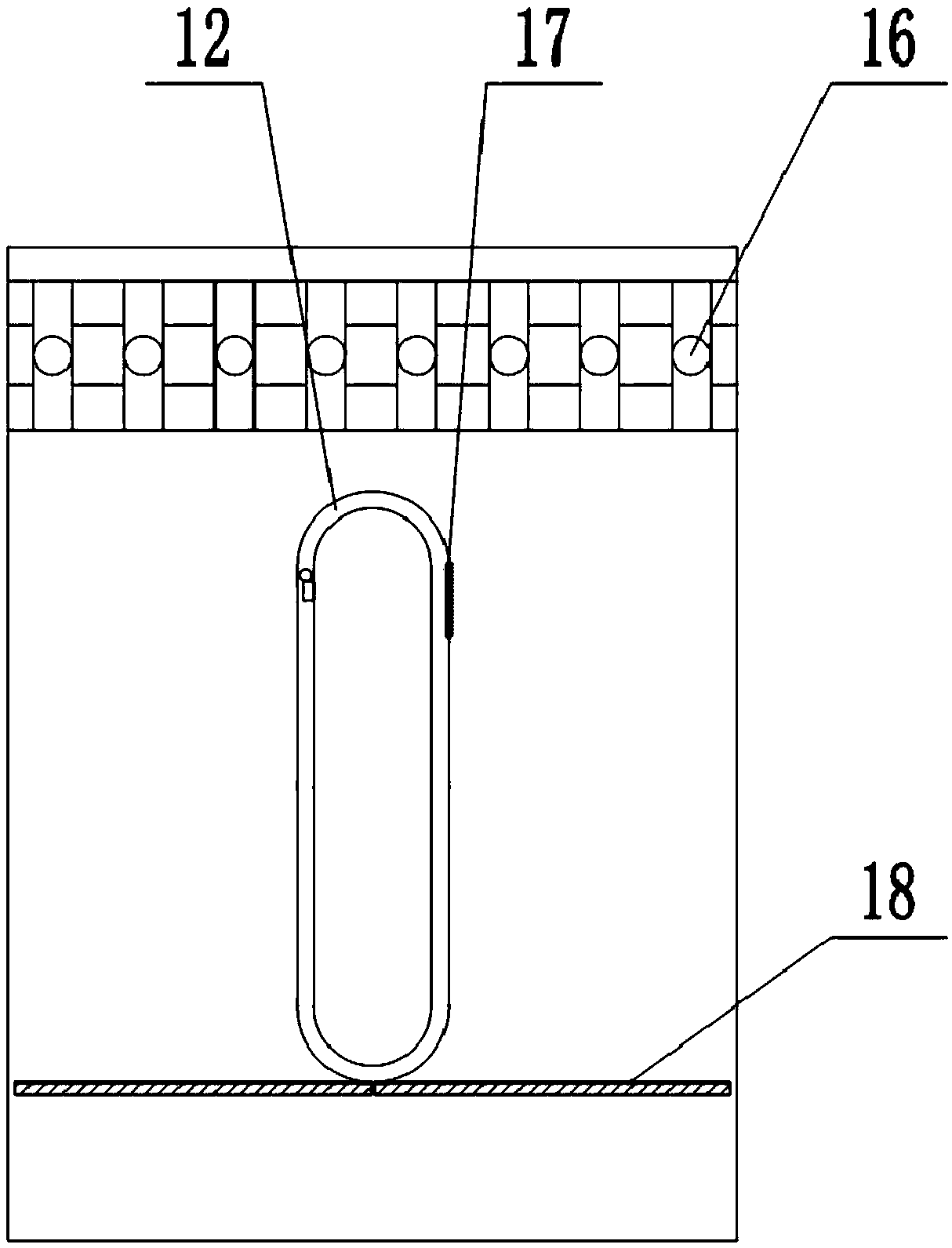

[0020] like figure 1 As shown, the dry and wet garbage bin of intelligent classification includes a power supply and an outer bucket 1. The outer bucket 1 is provided with an inner bucket 3 for dry objects and an inner bucket 2 for wet objects. A filter screen 19 and a dryer 20 are installed at the bottom of the inner bucket 2 for wet objects. There is a cavity between the inner drum 3 for dry objects and the inner drum 2 for wet objects, and the tops of the inner drum 3 for dry objects and the inner drum 2 for wet objects are provided with a lid 4 and a flip mechanism, and the side of the lid 4 away from the cavity is hinged to the outer drum 1, The other side is provided with a driving motor 9, the output shaft of the driving motor 9 is connected with a driving wheel 7, and a U-shaped pre-packing groove 5 is arranged between the two driving wheels 7, and the driving whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com