Dust collecting device at vertical straining portion of air cushion

A dust collector, air cushion technology, applied in loading/unloading, transportation and packaging, conveyors, etc., to reduce production and installation costs and improve overall environmental performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

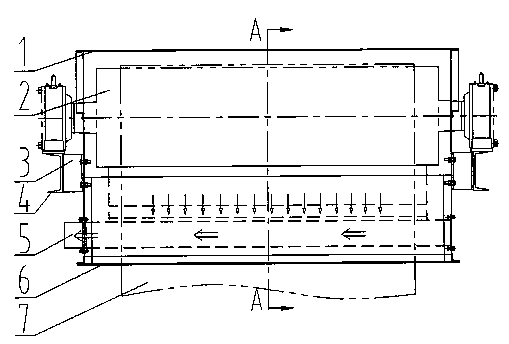

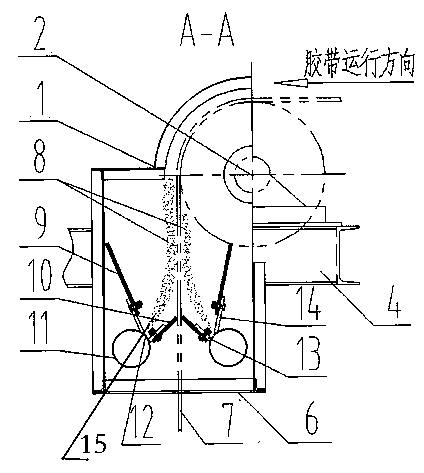

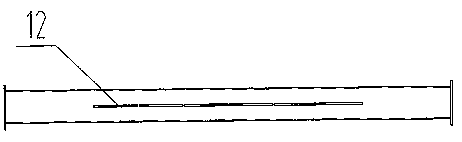

[0009] Specific examples figure 1 , figure 2 As shown, the box body 1 half surrounds the vertical pulling and redirecting drum 2, and the outer boxes on both sides of the box are connected to the connecting seat by bolts, and the connecting seat 3 is welded on the 4 sides inside the vertical pulling and redirecting drum base, and On the side wall of the box body, there are respectively fixed dust collection external pipes 11 on the front and rear belt surfaces of the conveyor belt 7. Each dust collection external pipe is proces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com