Warehouse goods efficient carrying facility

A technology for handling equipment and goods, applied in the field of efficient handling equipment for warehousing goods, can solve the problems of easy shaking of goods, insufficient protection of goods, scattering, etc., to avoid shaking and scattering, improve fixing effect, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

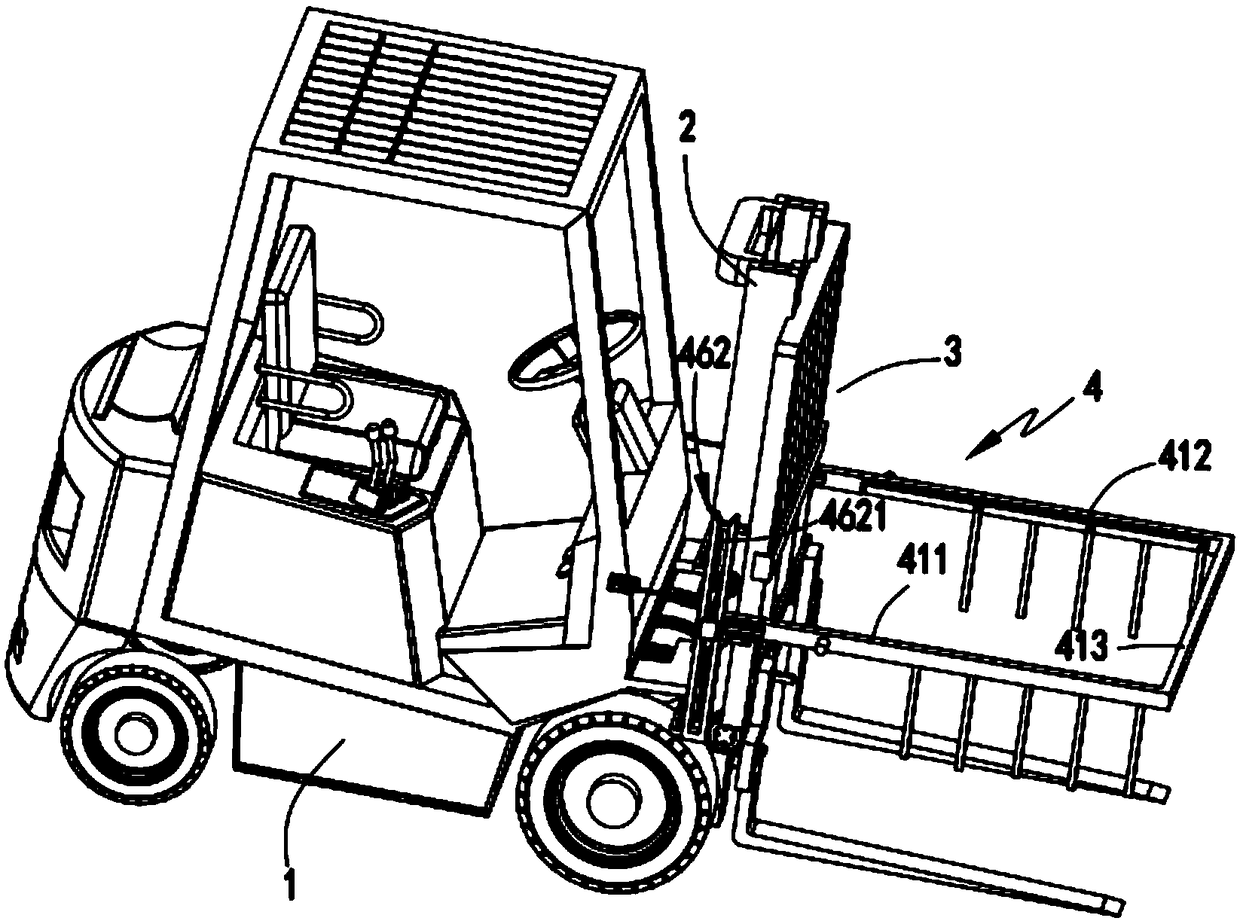

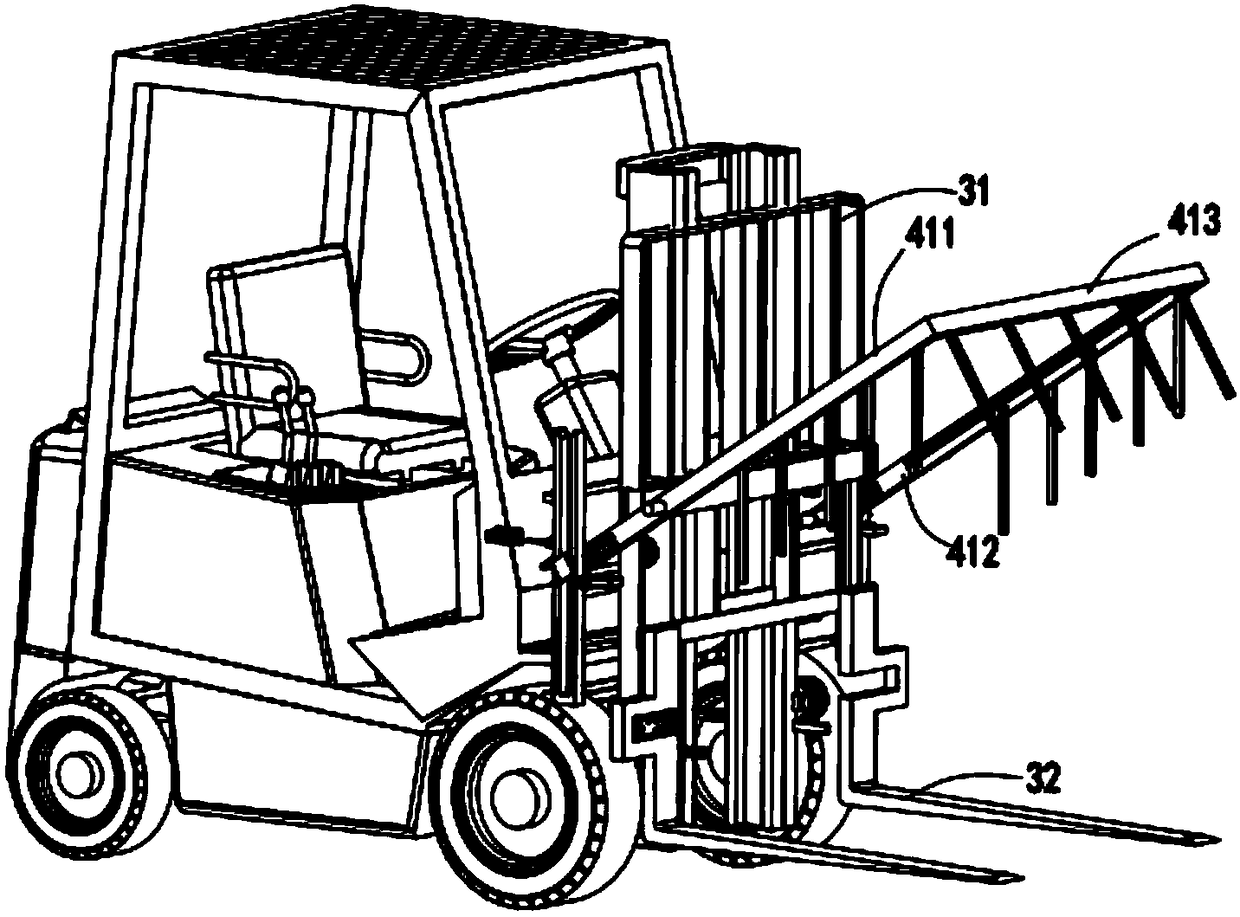

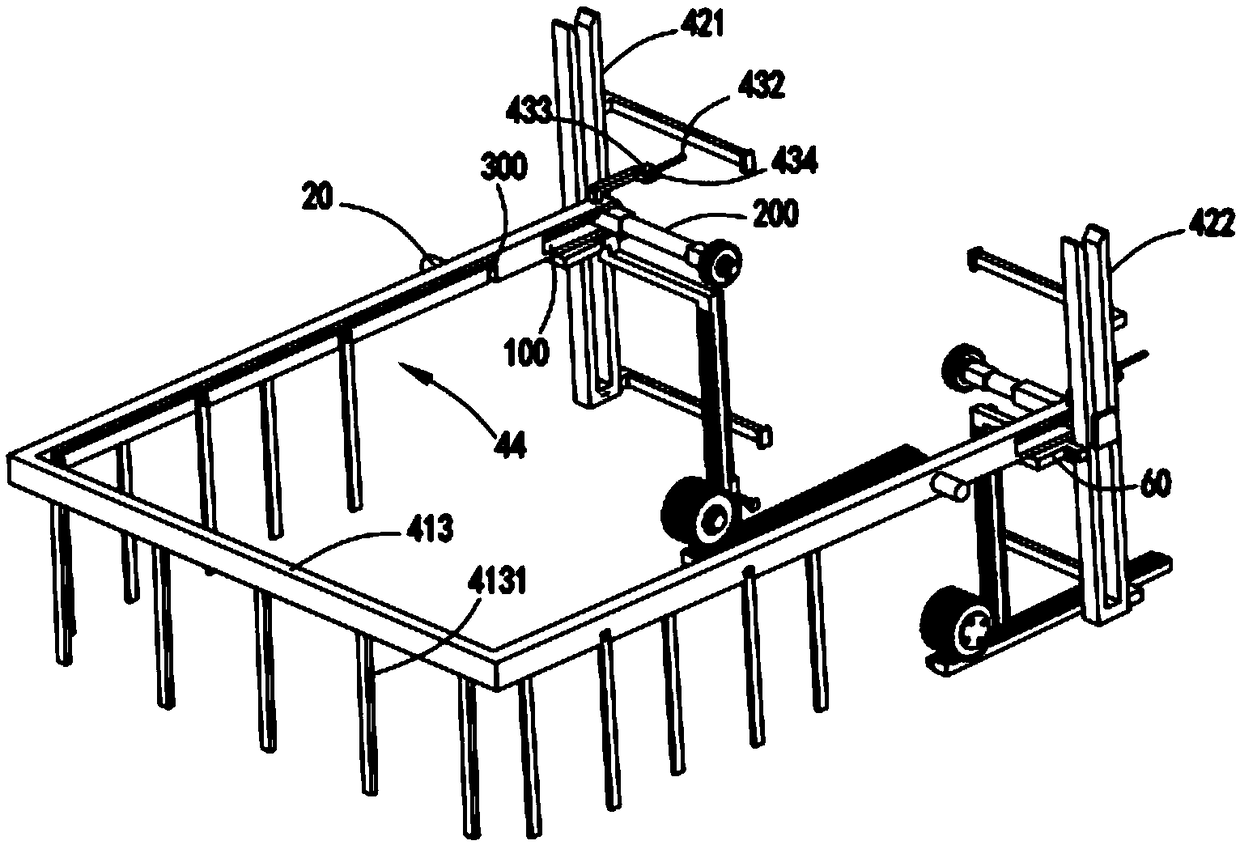

[0043] Such as Figure 1 to Figure 9As shown, a kind of high-efficiency handling equipment for stored goods includes a truck body 1, a door frame 2 arranged at the front of the truck body 1, a shelf 3 that moves up and down along the door frame 2, and a protective device 4. The protective device 4 includes a protective frame 41, a guide mechanism 42, a tightening mechanism 43, a clamping mechanism 44, a lifting mechanism 45, and a turning mechanism 46, and the tightening mechanism 43, the clamping mechanism 44, the lifting mechanism 45, and the turning mechanism 46 are all symmetrical There are two settings;

[0044] The protective frame 41 is used to prevent the goods on the shelf 3 from being scattered; the guide mechanism 42 is arranged on the side of the protective frame 41, and it is used to guide and limit the protective frame 41; the tightening mechanism 43 is arranged on the transport On the vehicle body 1, it is used to drive the protective frame 41 to move toward th...

Embodiment 2

[0063] Such as Figure 4 with Image 6 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between the second embodiment and the first embodiment is: further, the limit assembly 461 includes a third gear 4611 rotatably arranged on the side of the door frame 2 and fixed on the outer end surface of the third gear 4611 The limiting member 4612, the limiting member 4612 is provided with a card slot 4613, and correspondingly, at the end of the slider part 201 of the connecting part 200 opposite to the slider part 202, a card slot 4613 is provided. The limit block a4614, when the limit block a4614 is completely engaged in the slot 4613, the slider part 202 and the third gear 4611 are coaxial;

[0064] The turning assembly 462 includes a third rack ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com