Hydrosilylation type high-temperature silicon resin catalytic inhibition system as well as preparation method and application thereof

A high-temperature catalysis and silicone resin technology, which is applied in the field of high-temperature catalysis suppression systems, can solve the problems of limited application, exposed catalyst active components, and difficult pulverization of coated catalysts, and achieves the effect of reducing the possibility of internal stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

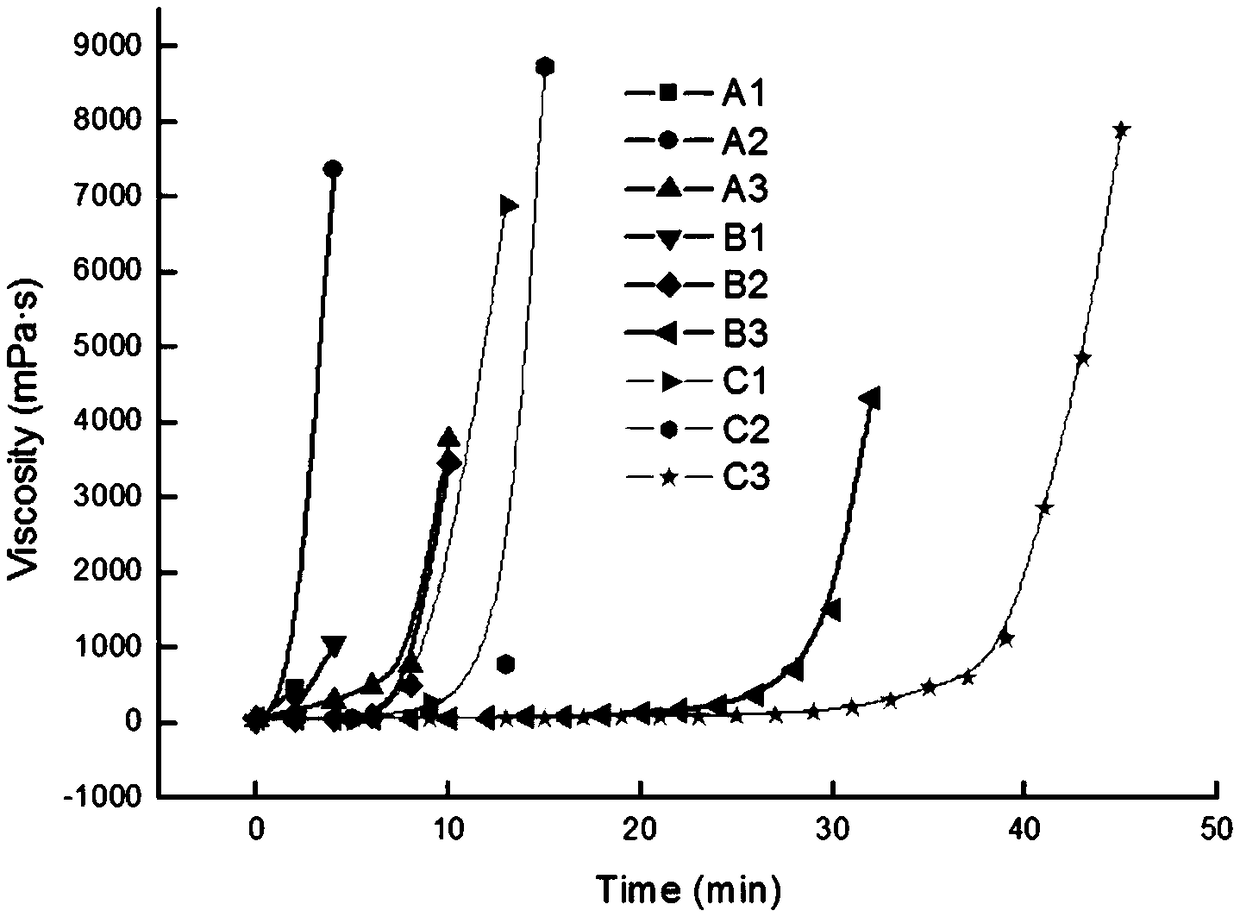

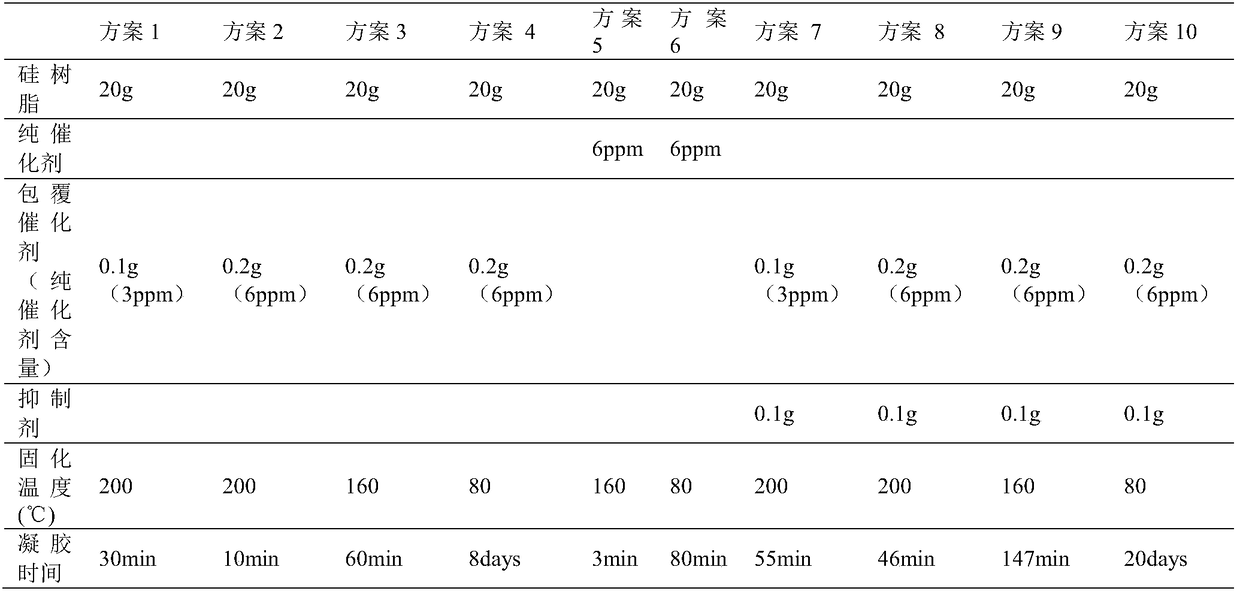

[0035] The invention relates to a method for preparing a hydrosilylation-type silicone resin high-temperature catalytic inhibitor system, including the preparation of an acetylenic alcohol-modified silane inhibitor and the preparation of a silicone-resin-coated platinum catalyst. The mass ratio of the silicone resin-coated platinum catalyst and the acetylenic alcohol-modified silane inhibitor is 1:1.

[0036] (1) The preparation method of acetylenic alcohol modified silane inhibitor:

[0037] a. In 80g toluene, add 25g 2-methyl-3-butyn-2-ol, 20g pyridine, and start stirring;

[0038] b. Slowly drop 15 g of phenyltrichlorosilane into the above solution, and complete the dropwise addition within 3 hours. After the dropwise addition, the temperature was raised to 120° C., and the stirring reaction was continued for 4 hours under reflux;

[0039] c. the above reactant is cooled to room temperature, and the solid generated by the reaction is filtered out with filter paper;

[00...

Embodiment 2

[0047] The invention relates to a method for preparing a hydrosilylation-type silicone resin high-temperature catalytic inhibitor system, including the preparation of an acetylenic alcohol-modified silane inhibitor and the preparation of a silicone-resin-coated platinum catalyst. The mass ratio of the silicone resin-coated platinum catalyst and the acetylenic alcohol-modified silane inhibitor is 1:1.

[0048] (1) The preparation method of acetylenic alcohol modified silane inhibitor:

[0049] a. In 80g toluene, add 5g 2-methyl-3-butyn-2-ol, 15g 2-phenyl-3-butyn-2-ol, 30g pyridine, and start stirring;

[0050] b. Slowly drop 27 g of phenyltrichlorosilane into the above solution, and complete the dropwise addition within 3 hours. After the dropwise addition, the temperature was raised to 120° C., and the stirring reaction was continued for 4 hours under reflux;

[0051] c. the above reactant is cooled to room temperature, and the solid generated by the reaction is filtered out...

Embodiment 3

[0059] The invention relates to a method for preparing a hydrosilylation-type silicone resin high-temperature catalytic inhibitor system, including the preparation of an acetylenic alcohol-modified silane inhibitor and the preparation of a silicone-resin-coated platinum catalyst. The mass ratio of the silicone resin-coated platinum catalyst and the acetylenic alcohol-modified silane inhibitor is 1:1.

[0060] (1) The preparation method of acetylenic alcohol modified silane inhibitor:

[0061] a. In 100g toluene, add 20g 2-methyl-3-butyn-2-ol, 5g 2-phenyl-3-butyn-2-ol, 10g3-methyl-4-pentyn-3- Alcohol, 30g pyridine, start stirring;

[0062] b. Slowly drop 31 g of phenyltrichlorosilane into the above solution, and complete the dropwise addition within 3 hours. After the dropwise addition, the temperature was raised to 120° C., and the stirring reaction was continued for 4 hours under reflux;

[0063] c. the above reactant is cooled to room temperature, and the solid generated ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com