A kind of weaving method of hole interconnected double-layer warp knitted fabric

A warp knitted fabric and hole technology is applied in the field of weaving of double-layer warp knitted fabrics with interconnected holes, which can solve the problems of not novel appearance of warp knitted mesh fabric and inability to improve the efficiency of production process, and achieve novel appearance and novel and unique style. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention discloses a weaving method of a double-layer warp knitted fabric with interconnected holes, which includes the following steps:

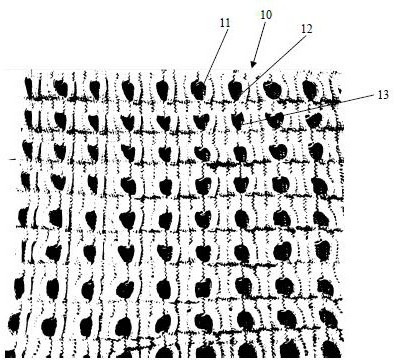

[0019] (1) With yarns and weaves, regular holes and vertical stripes are formed on the front of the fabric 10.

[0020] (2) Use the jacquard weave to selectively knit the front and back sides of the fabric 10 into loops to connect the front and back sides of the fabric 10. Specifically, where the holes are formed on the surface of the fabric 10, the longitudinal jacquard front and back sides of the hole edges are successively looped as the connecting layer, and the hole edges are not connected in the transverse direction, forming a hollow spacer wire effect of interconnecting holes.

[0021] (3) When the fabric 10 is forming holes and vertical strips, the yarn feeding amount of the knitting process is relaxed, so that the area where there is no jacquard weave connection will be raised to form holes during the subsequent shaping to smoo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com