High-flux soft-stamping-type vacuum interface valve

A soft-flushing, high-throughput technology, applied to valve details, diaphragm valves, valve devices, etc., can solve the problems of inability to meet absolute sealing effect, inability to obtain speed response control, short service life, etc., and achieve convenient speed response control Reliable, simple structure and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

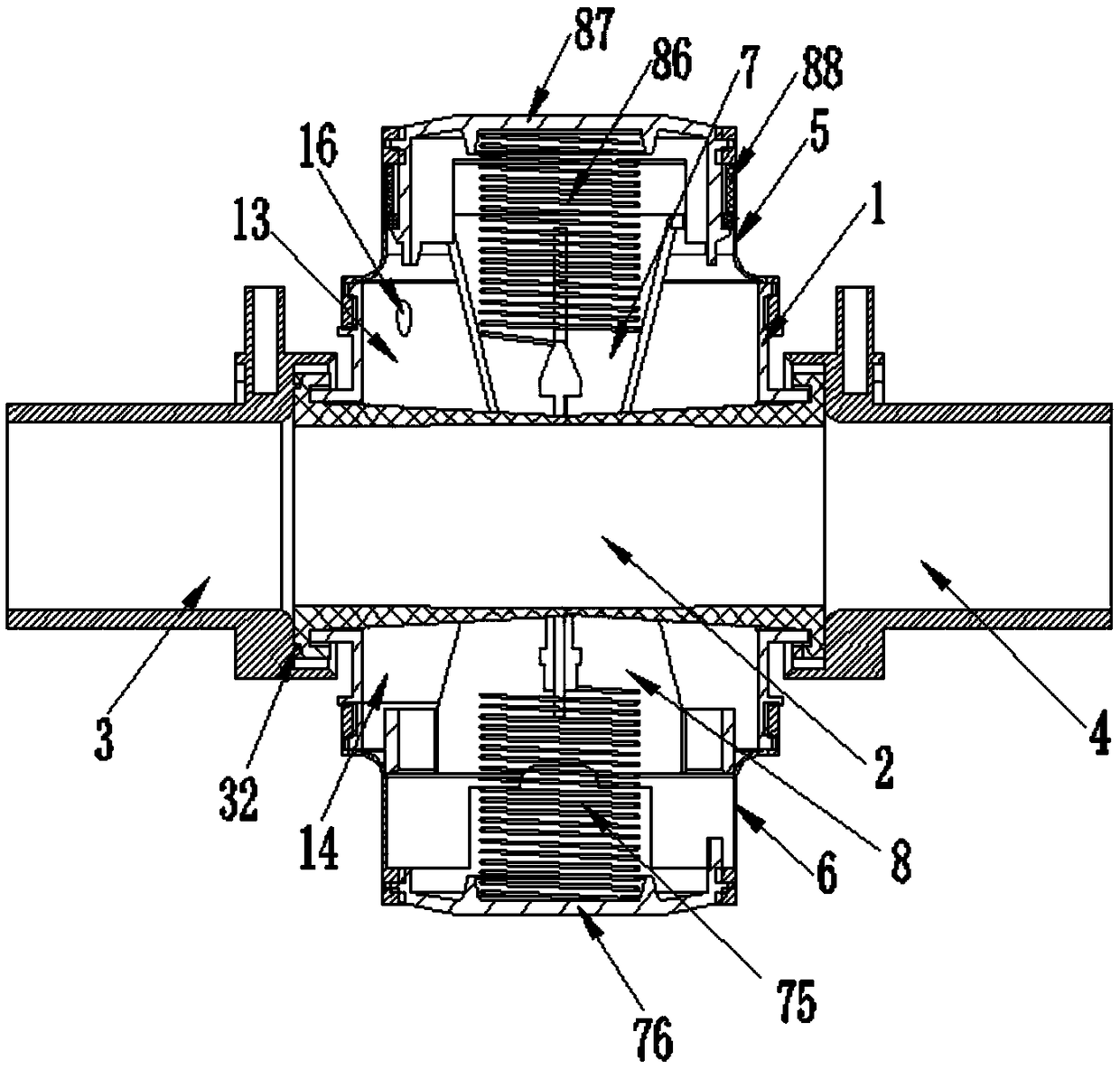

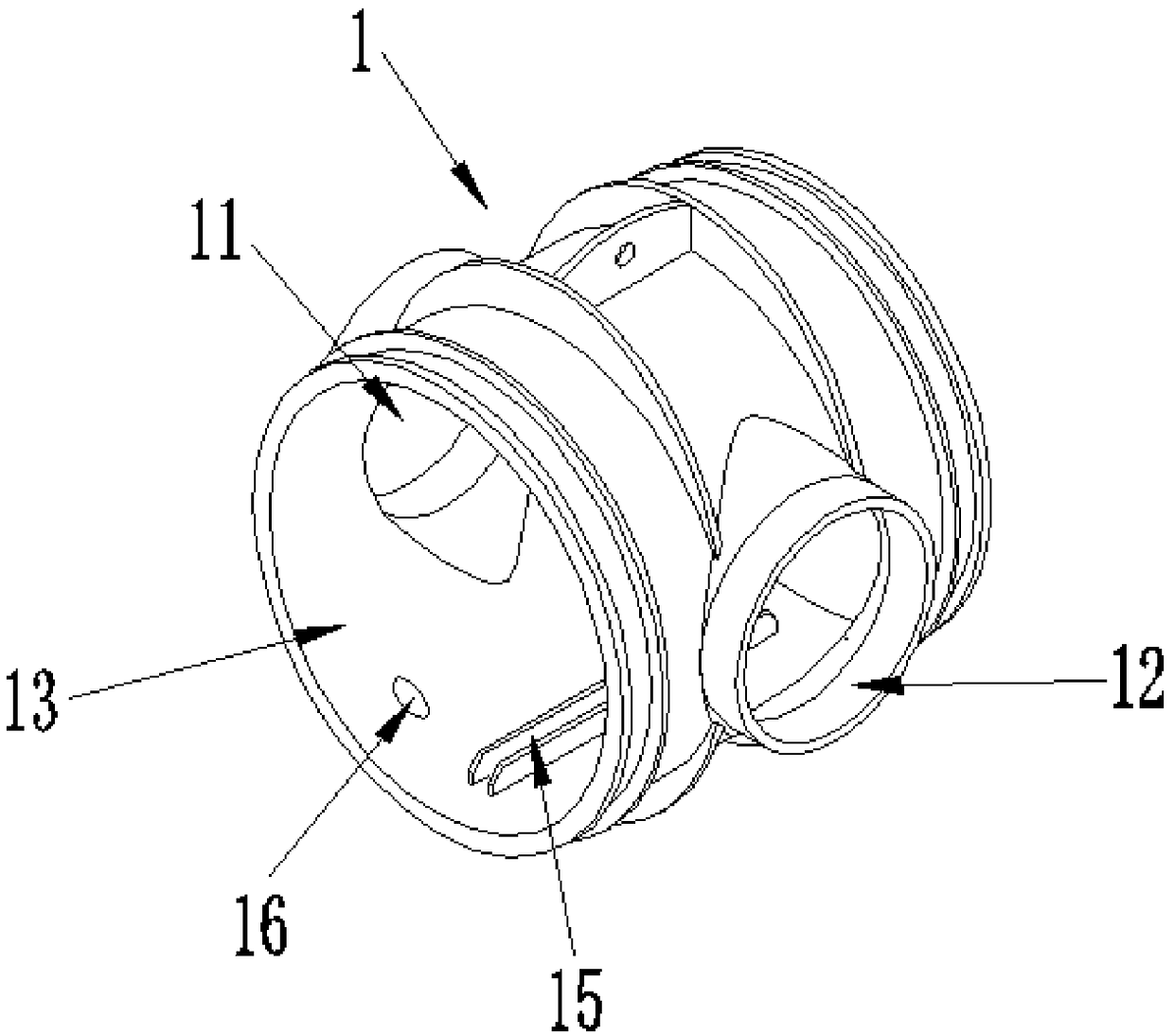

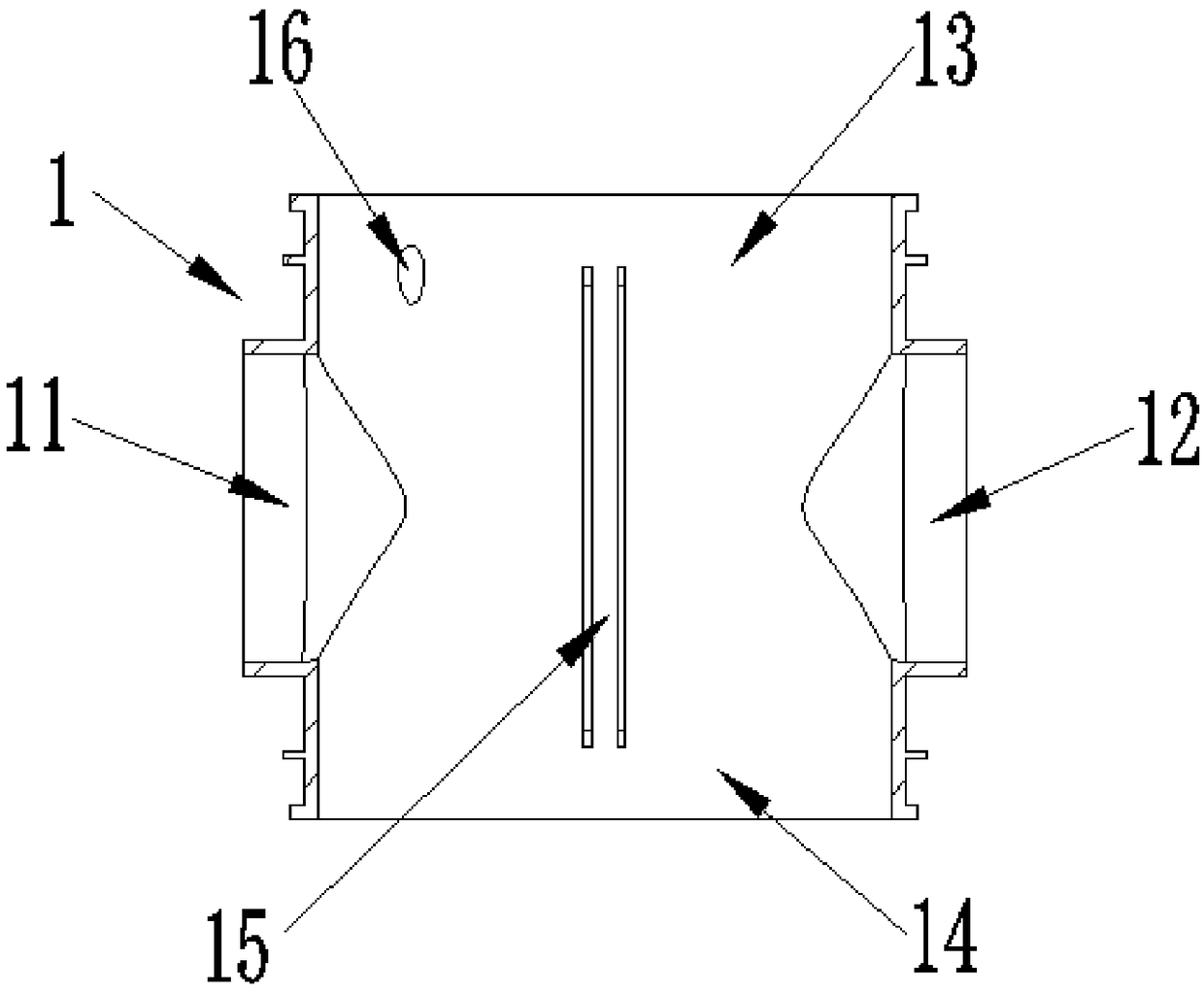

[0021] refer to Figure 1-Figure 9 , a high-throughput soft flush vacuum interface valve of the present invention, including a cross-connector 1, a hose 2, a water inlet pipe 3, a water outlet pipe 4, an upper diaphragm pressure plate 7, a lower diaphragm pressure plate 8, an upper gland 87 and a lower edge 9. A hose 2 is sleeved between the water inlet 11 and the outlet 12 of the cross 1; the outer end of the water inlet 11 of the cross 1 is provided with a water inlet 3, and the The outer end of the outlet pipe 12 is provided with a water outlet pipe 4; the cross channel 1 is provided with an upper diaphragm pressing plate 7 and a lower diaphragm pressing plate 8, and the inner sliding protrusion 82 of the lower diaphragm pressing plate 8 passes through the sliding length of the upper diaphragm pressing plate 7. In the gap 71, the upper pressure plate 72 at the lower end of the upper diaphragm pressure plate 7 and the lower pressure plate 83 of the lower diaphragm pressure p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com