Self-starting and stopping method of washing of rubber ball of condenser based on DCS

A condenser, self-start and stop technology, applied in the field of cooling water, can solve the problem of unable to meet the remote monitoring of the condenser, unable to directly monitor the cleaning effect of rubber balls, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

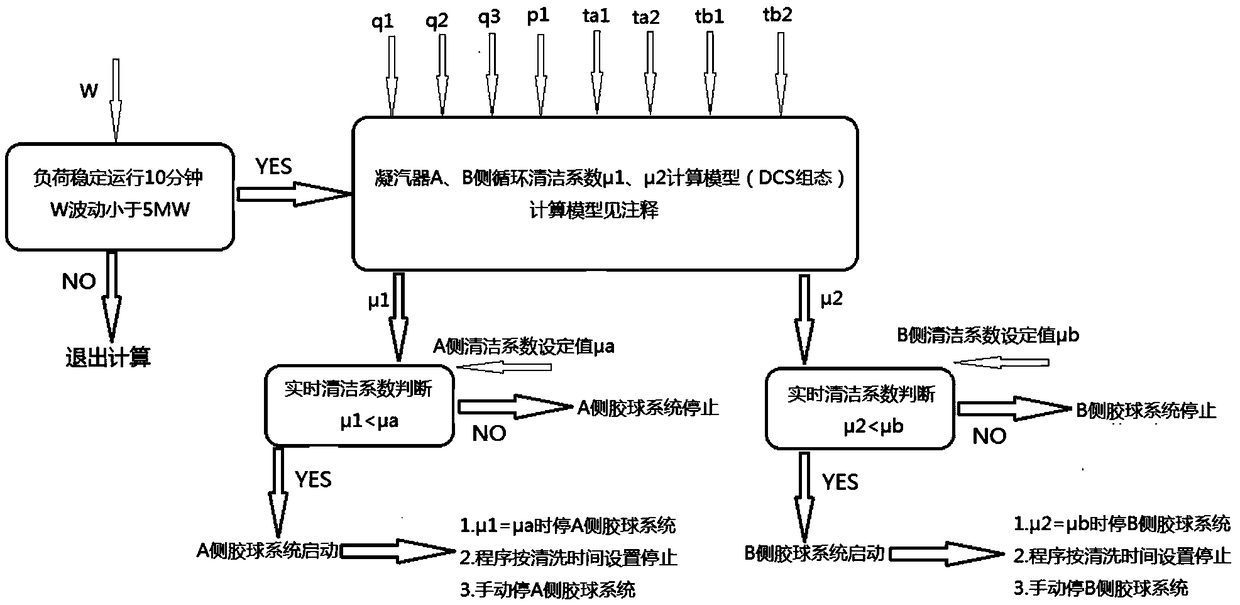

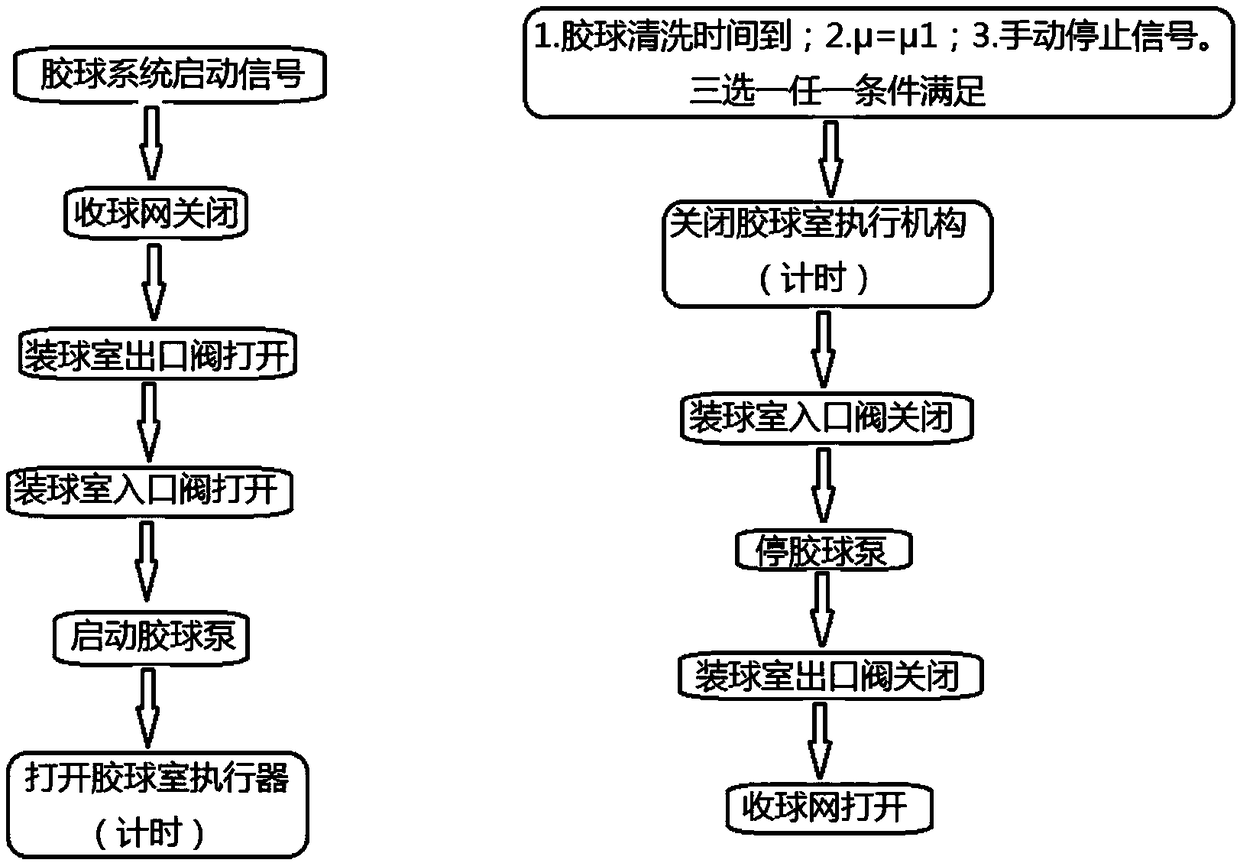

[0092] A DCS-based self-starting and stopping method for condenser rubber ball cleaning, comprising the following steps:

[0093] (1) Preset the cleaning coefficient μ of the water chamber on the side of condenser A in DCS a and the preset cleaning coefficient μ of the water chamber on the B side of the condenser b ;

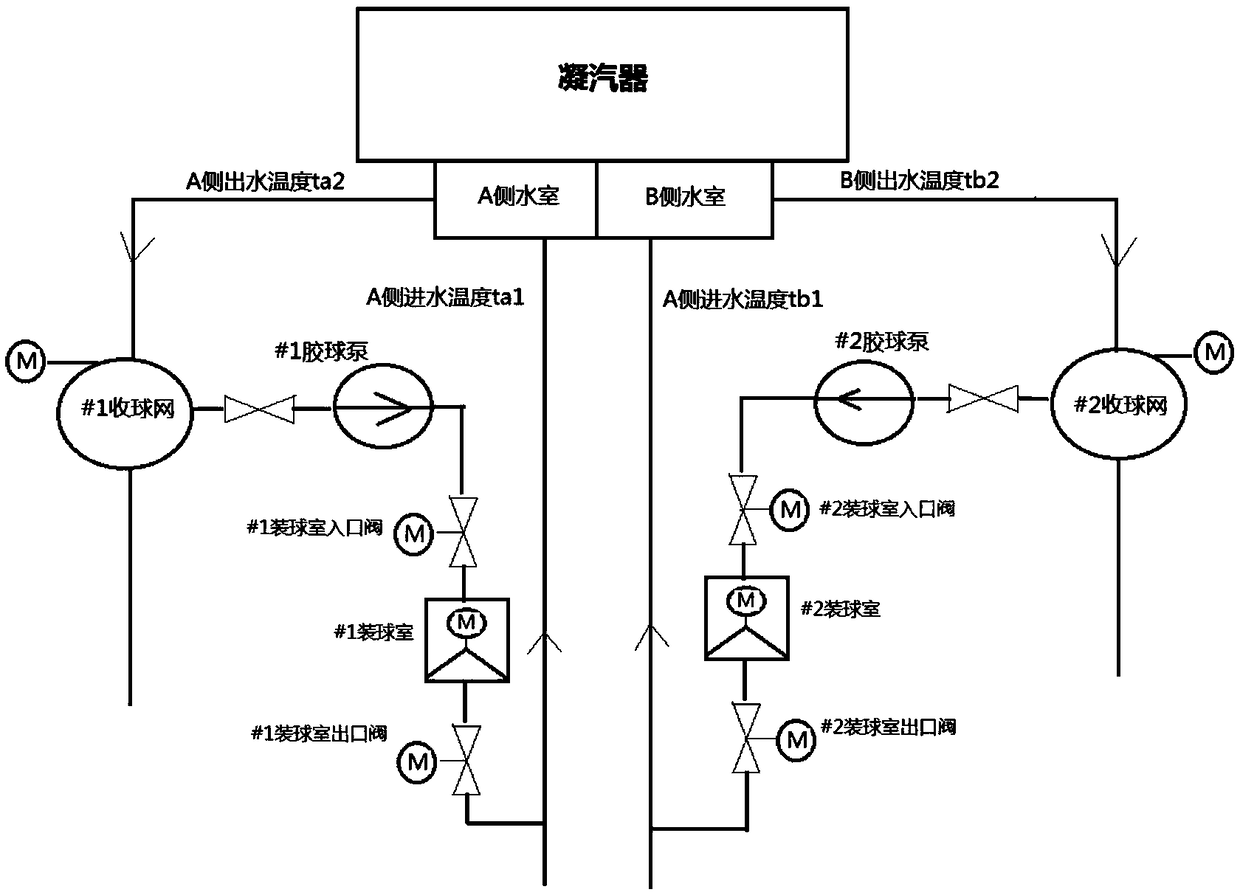

[0094] (2) Collect the working condition data of the condenser, including: high-pressure superheated steam flow q1, medium-pressure superheated steam flow q2, low-pressure superheated steam flow q3, condenser pressure p1, condenser circulating water A side inlet water temperature ta1, Condenser circulating water A side outlet temperature ta2, condenser circulating water B side inlet temperature tb1 and condenser circulating water B side outlet temperature tb2 data;

[0095] (3) Using the condenser working condition data collected in step (2), calculate the actual cleaning coefficient μ of the water chamber on the side A of the condenser circulating water throu...

Embodiment 2

[0167] A DCS-based self-starting and stopping method for condenser rubber ball cleaning, comprising the following steps:

[0168] (1) Preset the cleaning coefficient μ of the water chamber on the side of condenser A in DCS a and the preset cleaning coefficient μ of the water chamber on the B side of the condenser b ;

[0169] (2) Collect the working condition data of the condenser, including: high-pressure superheated steam flow q1, medium-pressure superheated steam flow q2, low-pressure superheated steam flow q3, condenser pressure p1, condenser circulating water A side inlet water temperature ta1, Condenser circulating water A side outlet temperature ta2, condenser circulating water B side inlet temperature tb1 and condenser circulating water B side outlet temperature tb2 data;

[0170] (3) Using the condenser working condition data collected in step (2), calculate the actual cleaning coefficient μ of the water chamber on the side A of the condenser circulating water throu...

Embodiment 3

[0178] A DCS-based self-starting and stopping method for condenser rubber ball cleaning, comprising the following steps:

[0179] (1) Preset the cleaning coefficient μ of the water chamber on the side of condenser A in DCS a and the preset cleaning coefficient μ of the water chamber on the B side of the condenser b ;

[0180] (2) When the condenser needs to run stably with load for more than 10 minutes and / or the load fluctuation of the unit is less than 5MW, collect the working condition data of the condenser, including: high-pressure superheated steam flow q1, medium-pressure superheated steam flow q2, low-pressure superheated steam flow q3 , condenser pressure p1, condenser circulating water A side inlet water temperature ta1, condenser circulating water A side outlet temperature ta2, condenser circulating water B side inlet temperature tb1 and condenser circulating water B side outlet water temperature tb2 data;

[0181] (3) Using the condenser working condition data co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com