Operation and maintenance management system and method

An operation and maintenance management and operation and maintenance technology, applied in the power field, can solve the problems of increasing operation and maintenance lines, reducing the efficiency of operation and maintenance management, and lack of professional business knowledge, so as to reduce the loss of human, material and financial resources and avoid repetitive work. , The effect of solving the shortage of operation and maintenance staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

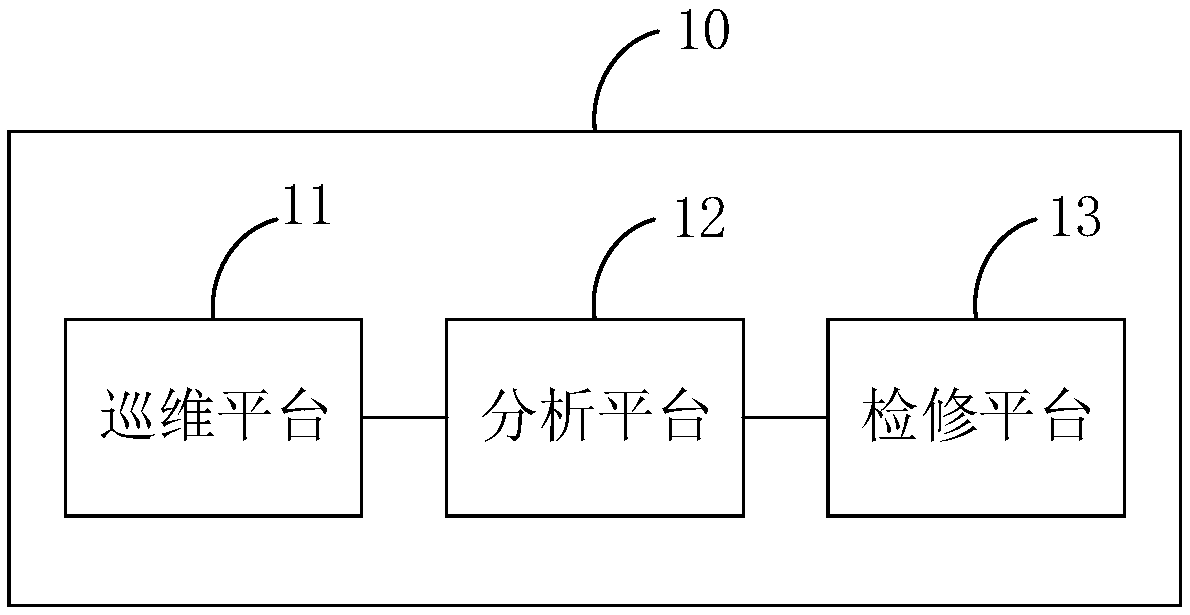

[0043] figure 1 It is a schematic structural diagram of an operation and maintenance management system proposed in the first embodiment of the present invention. The operation and maintenance management system 10 includes an inspection platform 11 , an analysis platform 12 and a maintenance platform 13 .

[0044] The inspection platform 11 is used to obtain the monitoring data of the line and send the monitoring data to the analysis platform 12 .

[0045] The inspection platform 11 acquires monitoring data in the transmission line through at least one connected monitoring device.

[0046] The monitoring equipment may include fixed-point monitoring equipment and / or mobile monitoring equipment, wherein the fixed-point monitoring equipment is monitoring equipment set at a predetermined position, and the mobile monitoring equipment is monitoring equipment carried by helicopters and / or drones.

[0047]The monitoring equipment may be a light radar rangefinder, an infrared thermome...

Embodiment 2

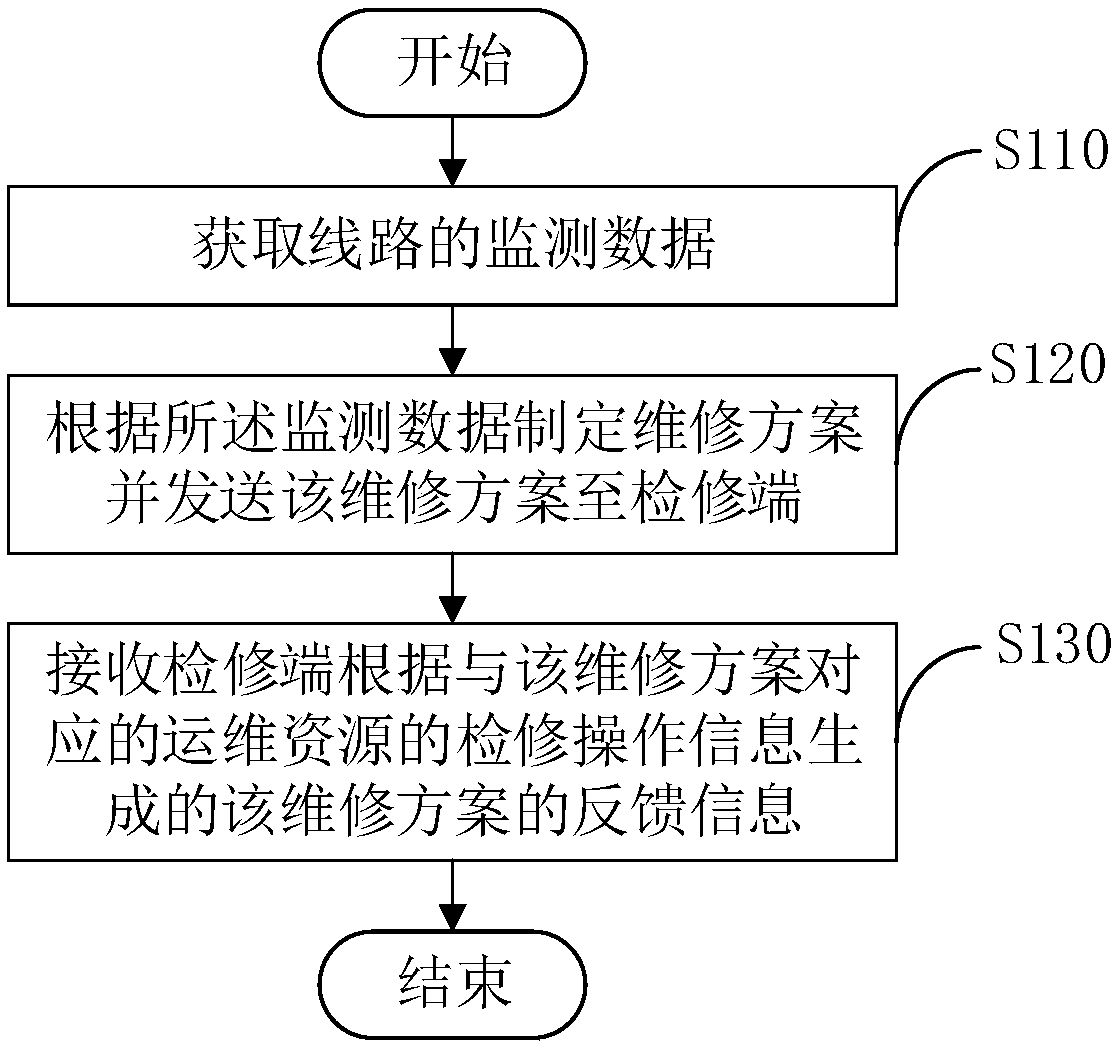

[0065] figure 2 It is a schematic flowchart of an operation and maintenance management method proposed in the first embodiment of the present invention.

[0066] Step S110, acquiring line monitoring data.

[0067] In this embodiment, the monitoring data of the line can be obtained through the monitoring equipment, and when the monitoring equipment cannot obtain the monitoring data of the relevant line or the confidence of the obtained monitoring data is lower than a predetermined value, a manual inspection command is issued to obtain the monitoring data of the relevant transmission line .

[0068] For example, the monitoring data can be acquired through monitoring equipment arranged at a predetermined location or carried by helicopters and / or unmanned aerial vehicles. In areas that cannot be inspected by monitoring equipment, the monitoring data obtained by manual inspection is obtained. In addition, the monitoring data obtained by the monitoring equipment can also be judg...

Embodiment 3

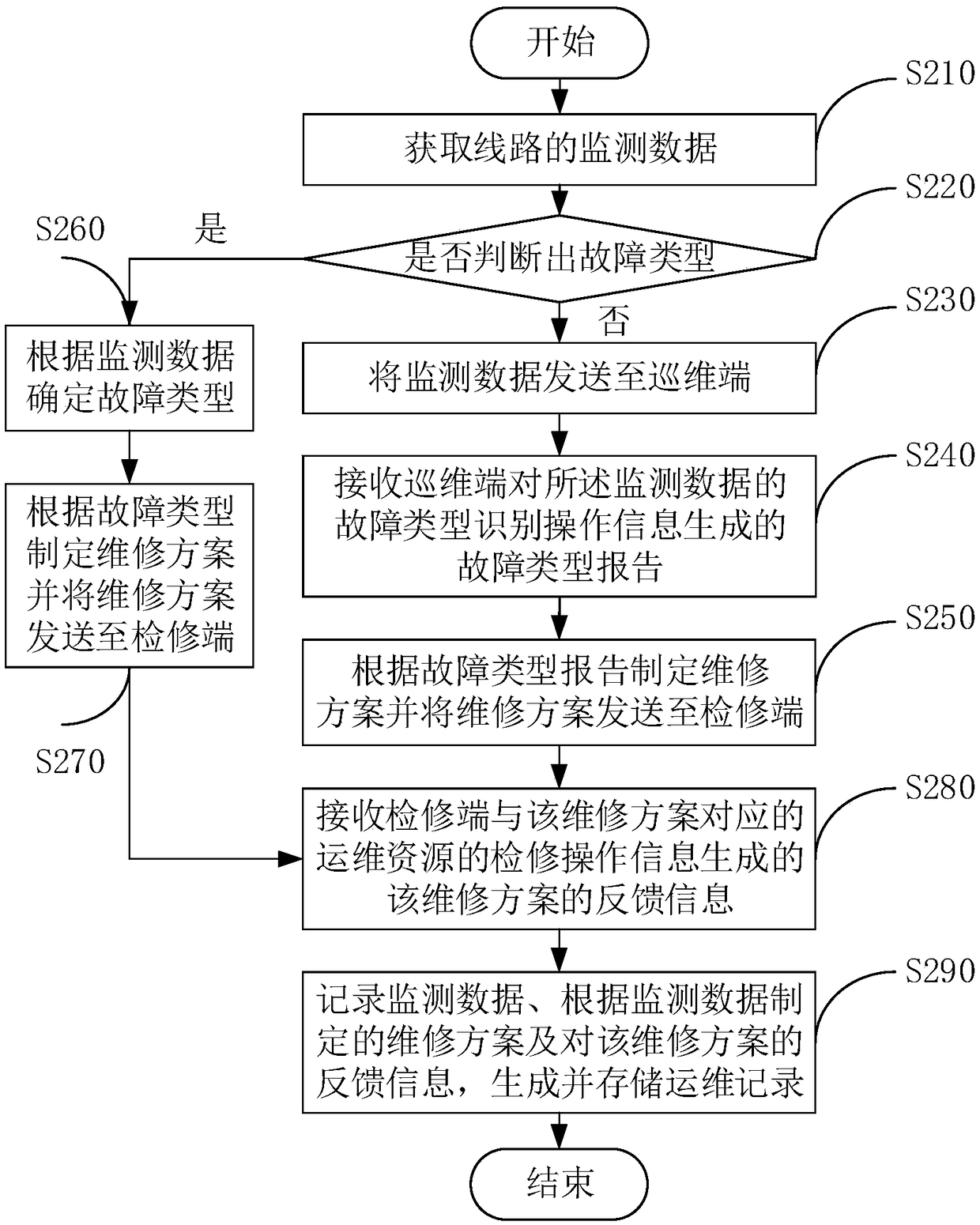

[0080] image 3 It is a schematic flowchart of an operation and maintenance management method proposed in the second embodiment of the present invention.

[0081] Step S210, acquiring line monitoring data.

[0082] Step S220, whether to determine the fault type.

[0083] The monitoring data is analyzed to determine whether the fault type corresponding to the monitoring data can be identified. For example, if the temperature value in the monitoring data increases significantly and exceeds the safe range, it is determined that the fault type is a defect caused by wildfire.

[0084] If the fault type of the monitoring data cannot be identified, proceed to step S230; otherwise, proceed to step S260.

[0085] Step S230, sending the monitoring data to the inspection terminal.

[0086] Step S240, receiving the fault type report generated by the inspection terminal for the fault type identification operation information of the monitoring data.

[0087] Receive the identification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com