Electromagnet coil skeleton

A technology of electromagnet coils and coil frames, which is applied in the direction of circuits, magnets, magnetic objects, etc., can solve problems such as troublesome winding of electromagnet coil frames, potential safety hazards, and paralysis of hydraulic systems, so as to avoid accidents and reduce safety Hidden dangers, the effect of improving the protection level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

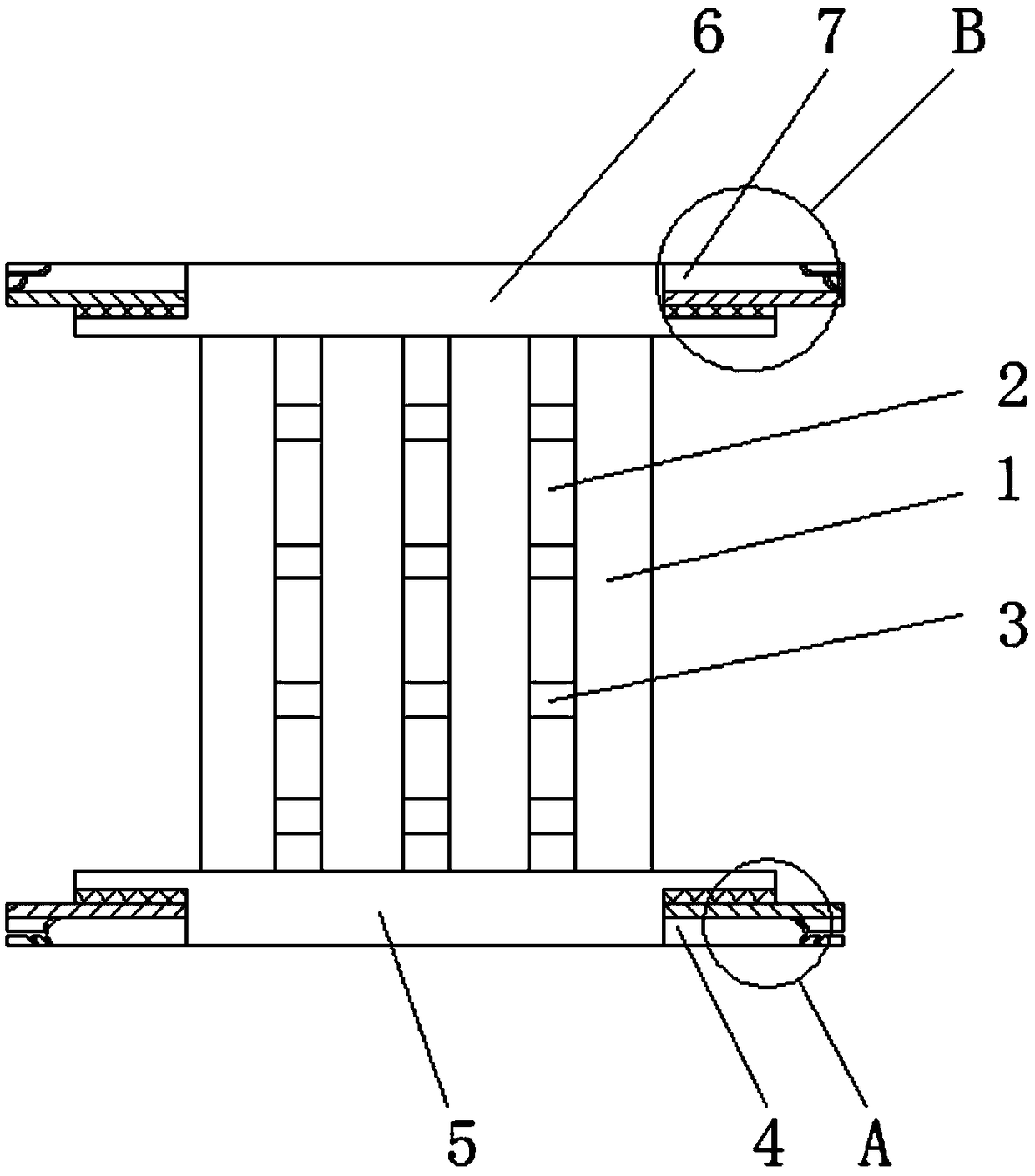

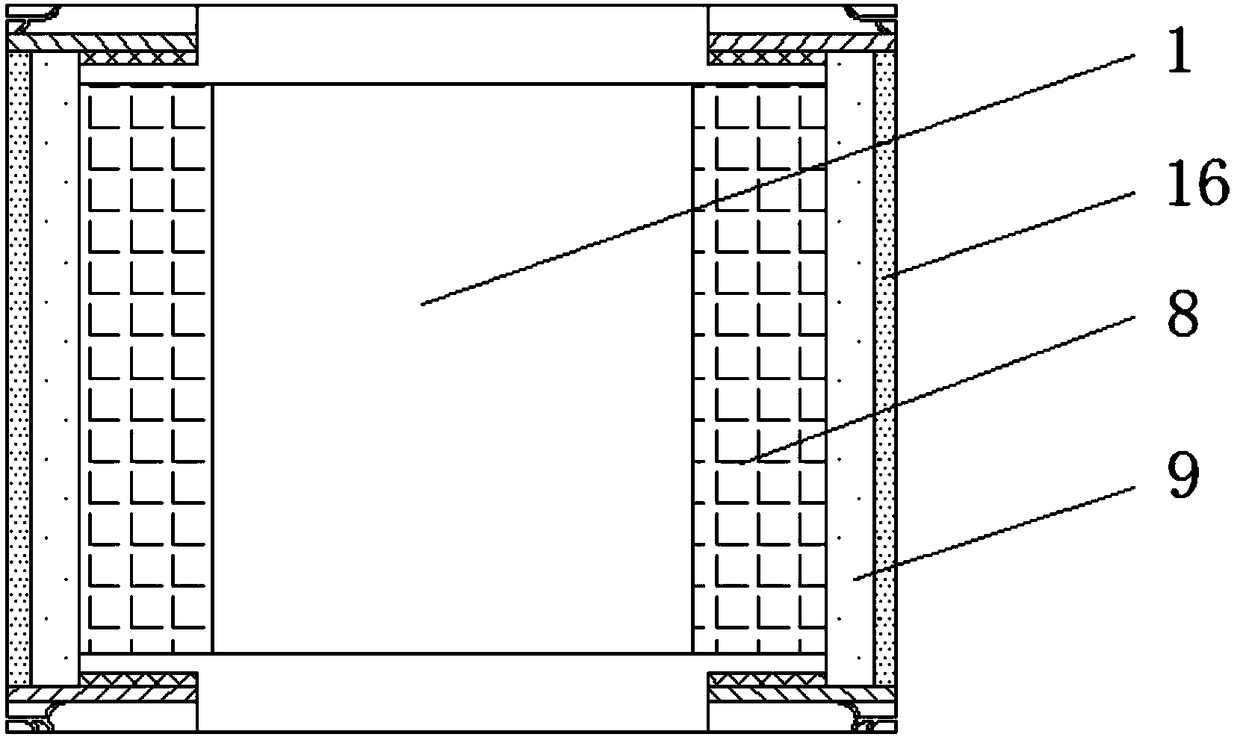

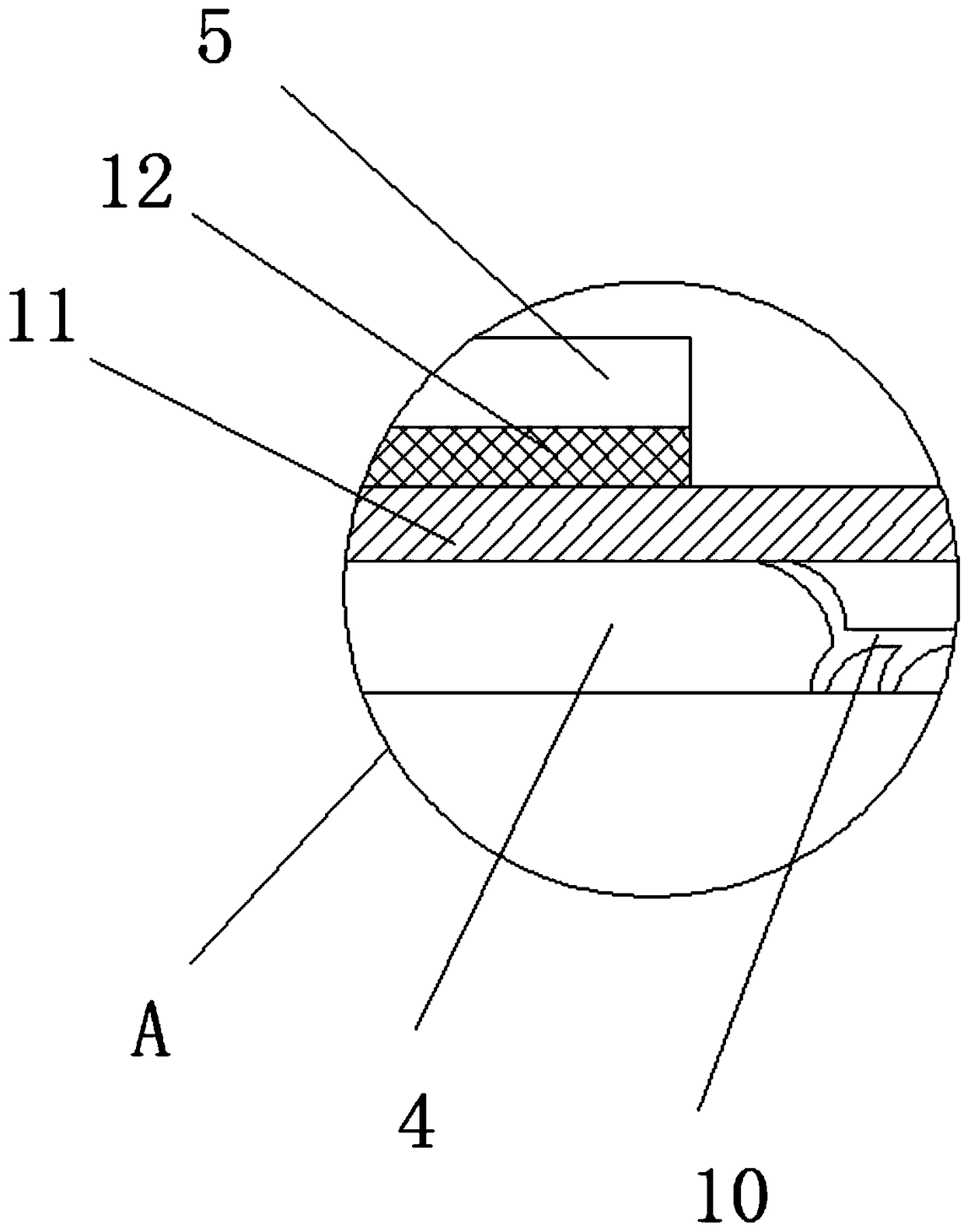

[0021] refer to Figure 1-4 , an electromagnet coil bobbin, comprising a coil bobbin main body 1, the shape and structure of the coil bobbin main body 1 is set as a cylindrical structure, the outer surface of the coil bobbin main body 1 is longitudinally uniformly fixed and connected with a plurality of strips 2, and a plurality of strips 2 A plurality of winding openings 3 are evenly opened on the surface of the coil bobbin main body 1. The lower surface of the coil bobbin main body 1 is fixedly connected with a bottom connecting plate 5, and the side wall of the bottom connecting plate 5 is fixedly connected with two first fixing plates 4, and the two first The ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com