Multilayer ceramic capacitor and preparation method thereof

A multi-layer ceramic and capacitor technology, applied in the direction of multilayer capacitors, fixed capacitor electrodes, fixed capacitor dielectrics, etc., can solve the problems of incomplete removal of adhesives, decreased density and uniformity of ceramic bodies, etc., to achieve good consistency , good density and good dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

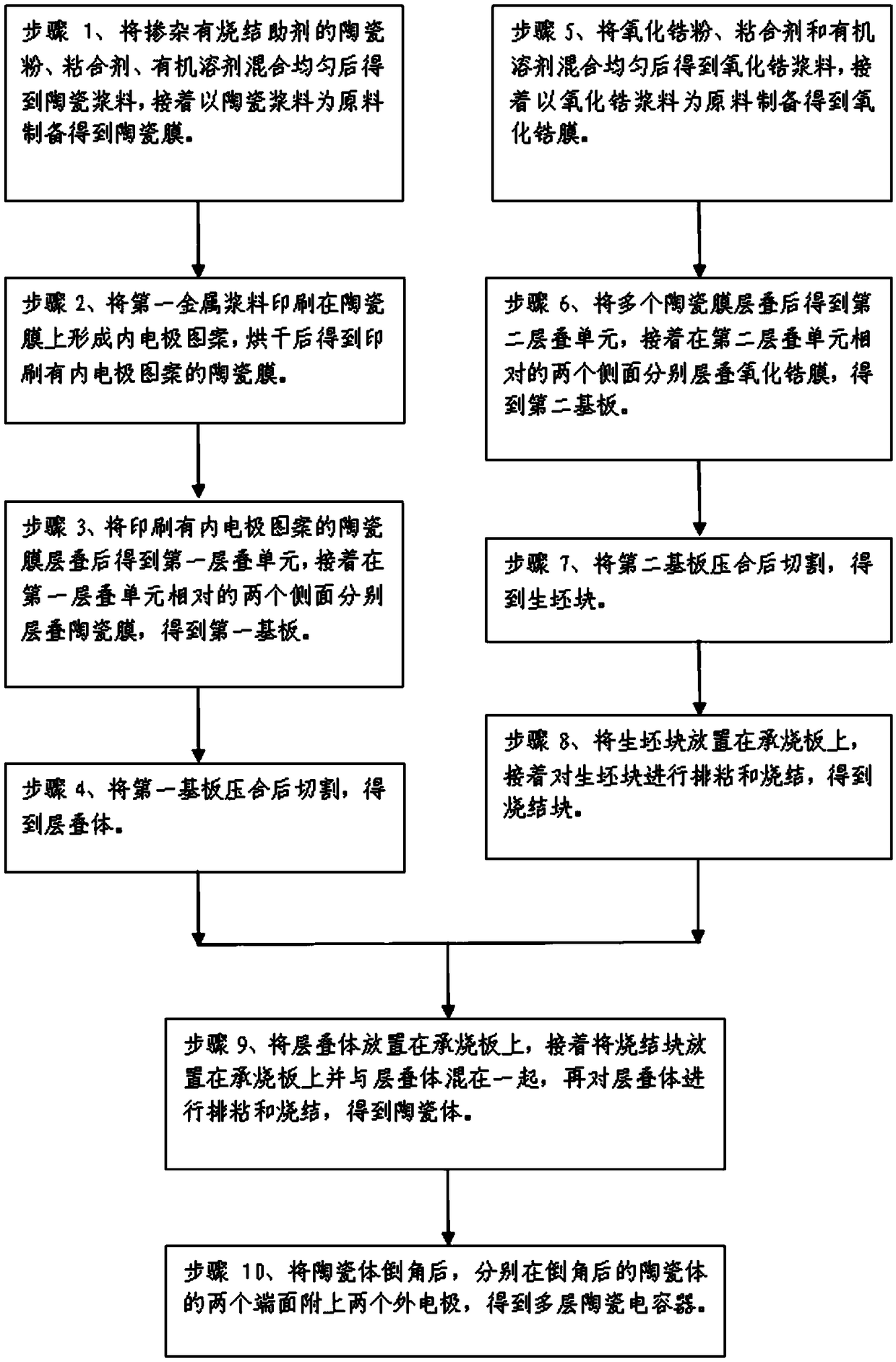

[0060] An embodiment of the multilayer ceramic capacitor of the present invention, combined with figure 1 , the multilayer ceramic capacitor described in this embodiment is prepared by the following method:

[0061] Step 1: Mix ceramic powder doped with sintering aid, binder, and organic solvent uniformly to obtain a ceramic slurry, and then use the ceramic slurry as a raw material to prepare a ceramic film.

[0062] In this embodiment, the operation of uniformly mixing the ceramic powder doped with sintering aid, the binder, and the organic solvent is as follows: the ceramic powder doped with the sintering aid, the adhesive, and the organic solvent are uniformly mixed by ball milling , The ball milling time can be 10h ~ 16h.

[0063] In the ceramic slurry, the mass ratio of the ceramic powder doped with the sintering aid, the binder and the organic solvent is 10:(3-5):(6-9).

[0064] In this embodiment, in the ceramic powder doped with the sintering aid, the mass percentage...

no. 2 approach

[0106] An embodiment of the multilayer ceramic capacitor of the present invention, the multilayer ceramic capacitor described in this embodiment is prepared by the following method:

[0107] Steps 1 to 5 are the same as those in the first embodiment.

[0108] Step 6: Laminate the zirconia film to obtain the second laminated unit, then laminate a plurality of ceramic films on the opposite sides of the second laminated unit to obtain the third laminated unit, and then respectively laminate the two opposite sides of the third laminated unit Zirconia films were laminated to obtain a second substrate.

[0109] Step 7: Pressing the second substrate and cutting it to obtain a green body.

[0110] Step 7 may specifically be: pressing the second substrate together by isostatic pressing to closely bond the film layers in the second substrate; then cutting the second substrate vertically and horizontally according to a predetermined size to obtain multiple green blocks.

[0111] The gr...

no. 3 approach

[0120] An embodiment of the multilayer ceramic capacitor of the present invention, the multilayer ceramic capacitor described in this embodiment is prepared by the following method:

[0121] Steps 1 to 5 are the same as those in the first embodiment.

[0122] Step 6: Print nickel paste on the ceramic film obtained in step 1 to form an additional layer, laminate the ceramic film printed with the additional layer to obtain a second laminate unit, and then laminate zirconia on the two opposite sides of the second laminate unit film to obtain a second substrate.

[0123] In the operation of printing nickel paste on the ceramic film to form an additional layer, the screen printing process is selected for printing. The thickness of the additional layer may be 2-5 μm.

[0124] Generally, the second lamination unit can be obtained by laminating 4 to 38 ceramic films printed with additional layers, and the number of zirconia films laminated on two opposite sides of the second laminat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap