A fin-based ionic wind cooling device

A technology of heat dissipation device and ionized wind, which is applied to the cooling/heating device of lighting device, lighting device, cooling/ventilation/heating renovation, etc. Avoid local backflow, improve heat exchange efficiency, and increase the effect of heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments, but it is not used as a basis for any limitation of the present invention.

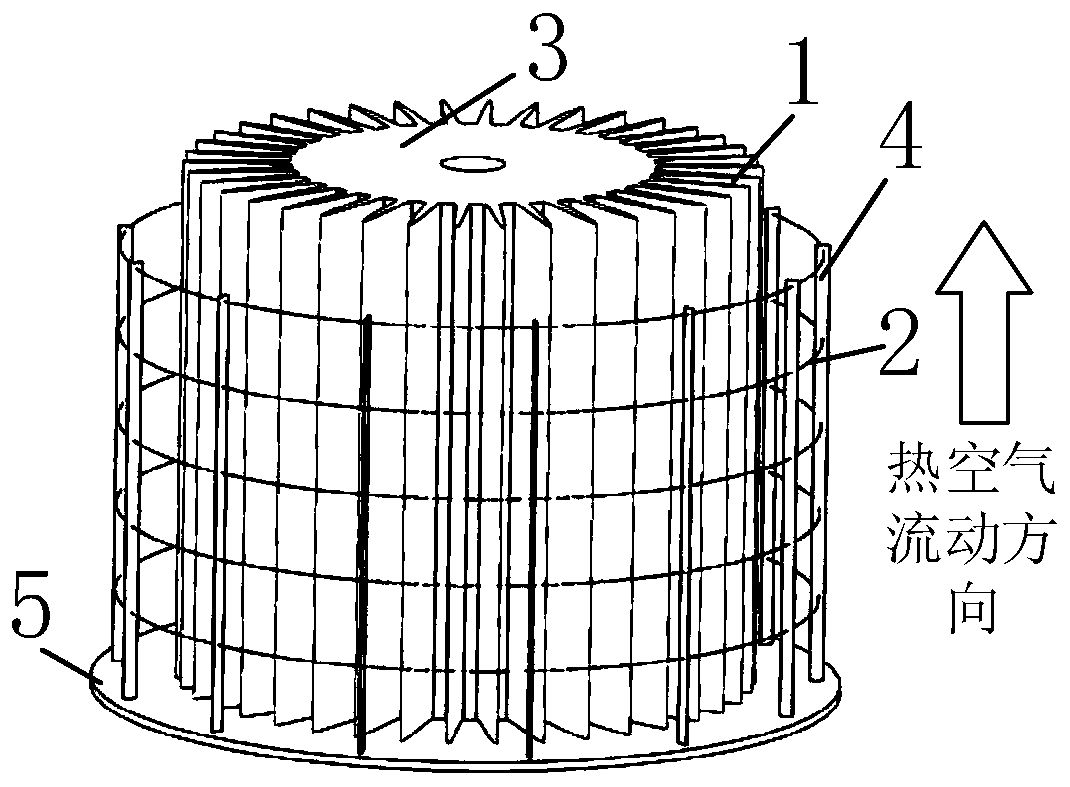

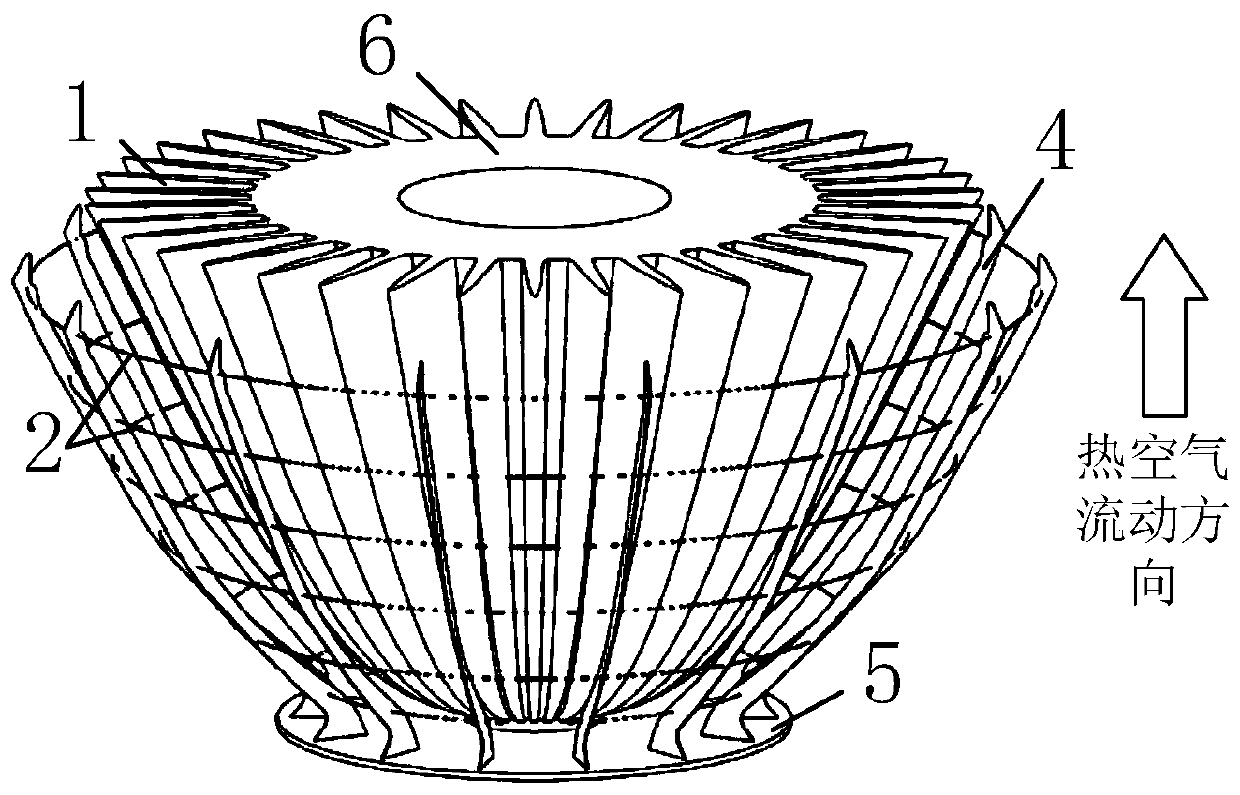

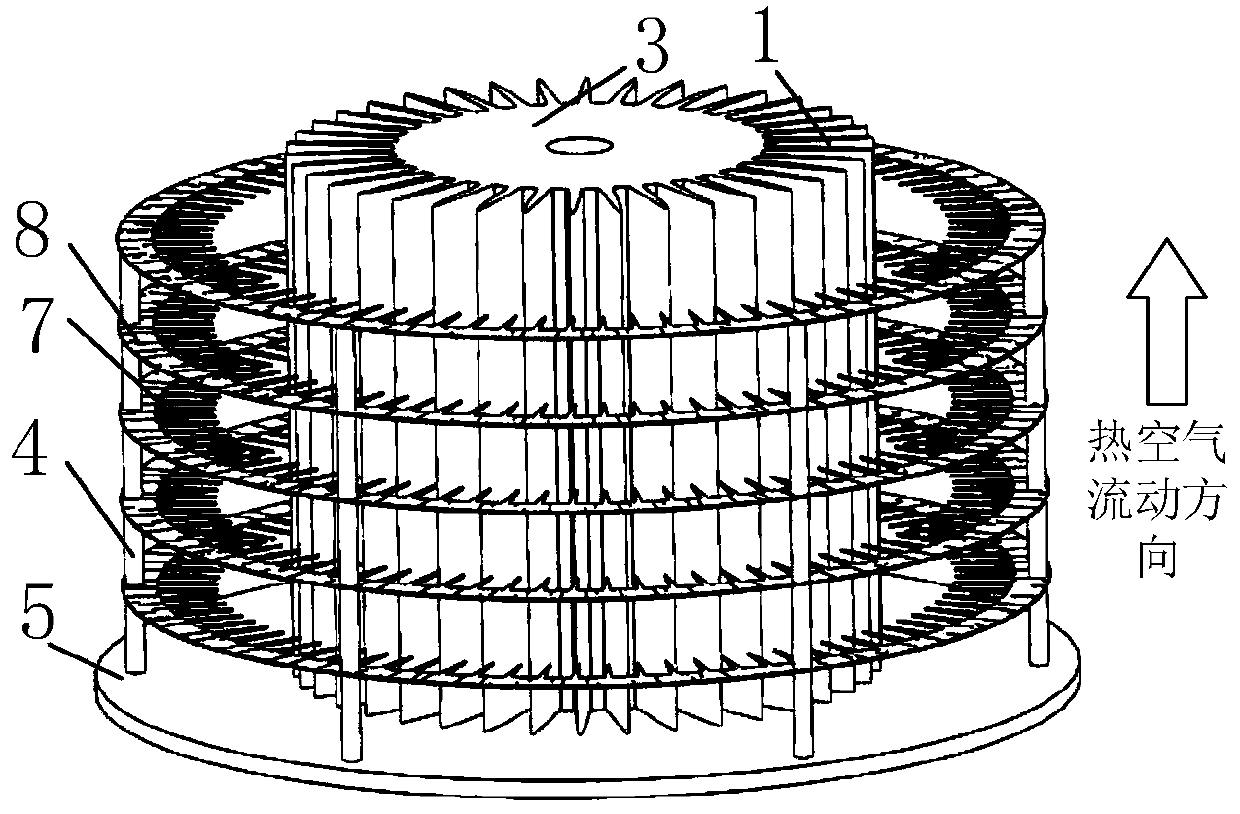

[0026] A fin-based ion wind cooling device of the present invention includes a metal radiator and an ion wind electrode, the metal radiator is provided with fins, and the outer envelope surface of the metal radiator is a rotating body; several layers of ion wind electrodes are in accordance with Equally spaced around the side of the metal radiator, and the ion wind electrode is facing the metal radiator fins; the ion wind moves from the surrounding to the metal radiator, and the air heated by the metal radiator moves from bottom to top, forming an efficient air flow mode, The phenomenon that the motions of the hot air and the air corona ion wind cancel each other out is avoided. The distance between the fins of the metal radiator is less than 1 / 3 of the distance from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com