Three-dimensional low-temperature baking device

A low-temperature baking, three-dimensional technology, applied in baking, food science, applications, etc., can solve the problems of uneven heating of oats, difficult to control the quality of oats, and achieve the effect of speeding up relative movement, improving the taste of finished oat products, and improving baking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

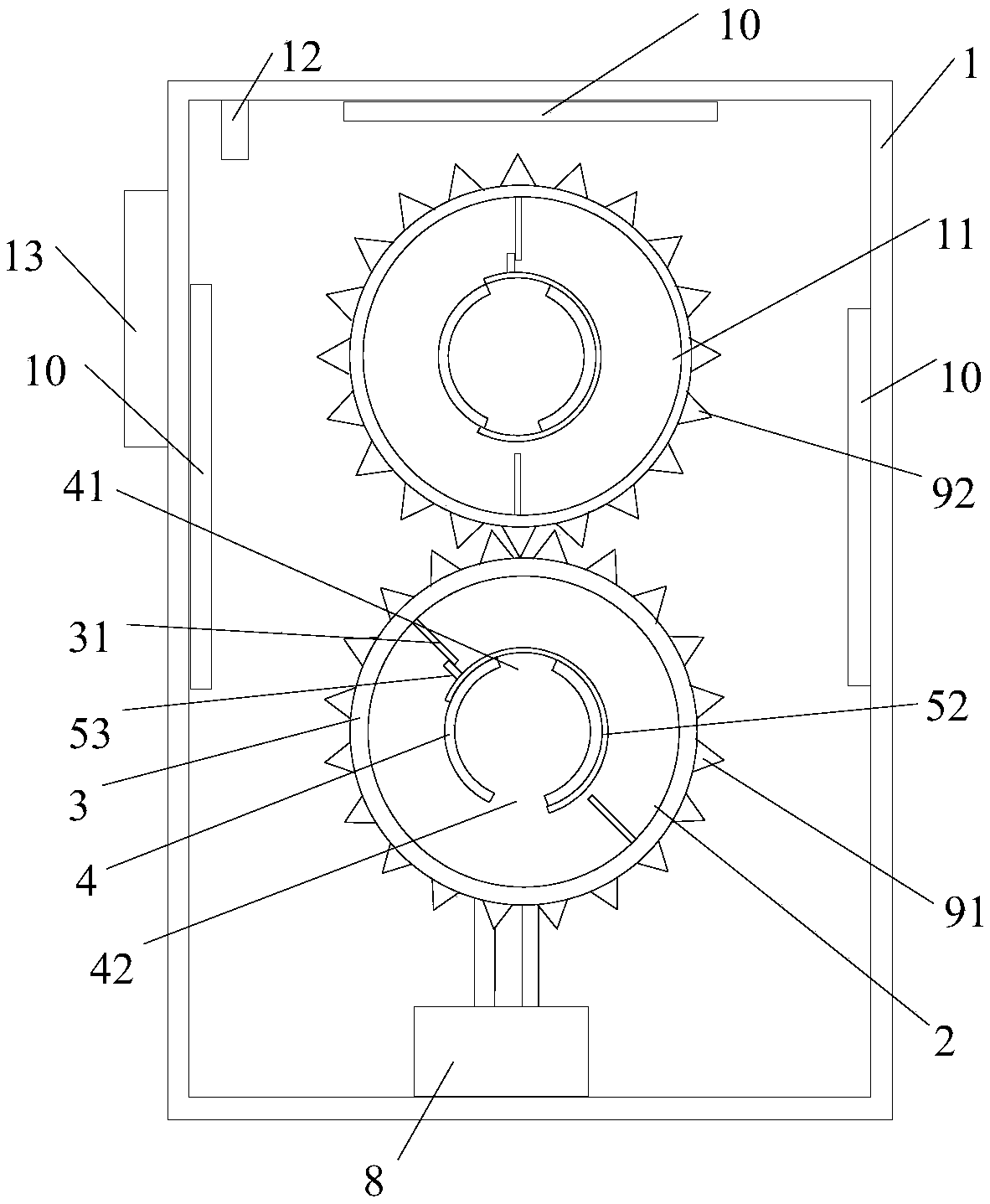

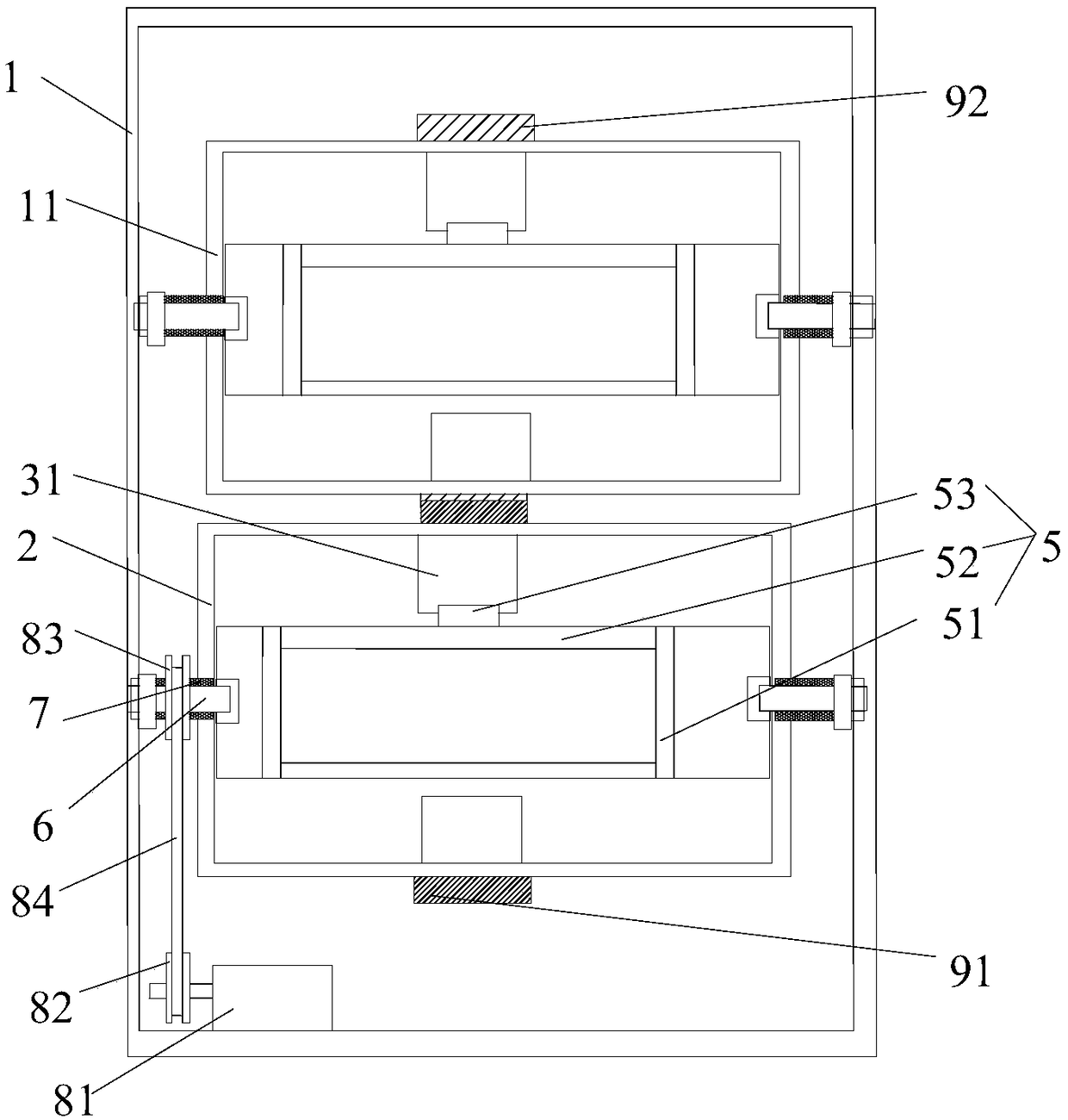

[0037] Such as Figure 1-2 As shown, the sliding mechanism 5 includes a slide rail 51 arranged along the outer wall of the buffer inner cylinder 4 and perpendicular to the central axis of the buffer inner cylinder, an arc-shaped slide plate 52 slidably connected to the slide rail 51 , and an arc-shaped slide plate 52 vertically arranged outside the buffer inner cylinder 52. The drive baffle 53 whose surface is pushed by the driving plate 31, the slide rail 51 is arranged in a ring, and the sliding tracks of the arc-shaped sliding plate 52 completely cover the upper opening 41 and the lower opening 42 respectively successively. The driving plate on the inner wall of the baking outer cylinder 3 31 is set corresponding to the position of the transmission baffle 53, the sum of the height of the driving plate 31 and the height of the transmission baffle 53 is greater than 1 / 2 of the difference between the inner diameter of the baking outer cylinder 3 and the outer diameter of the bu...

Embodiment 2

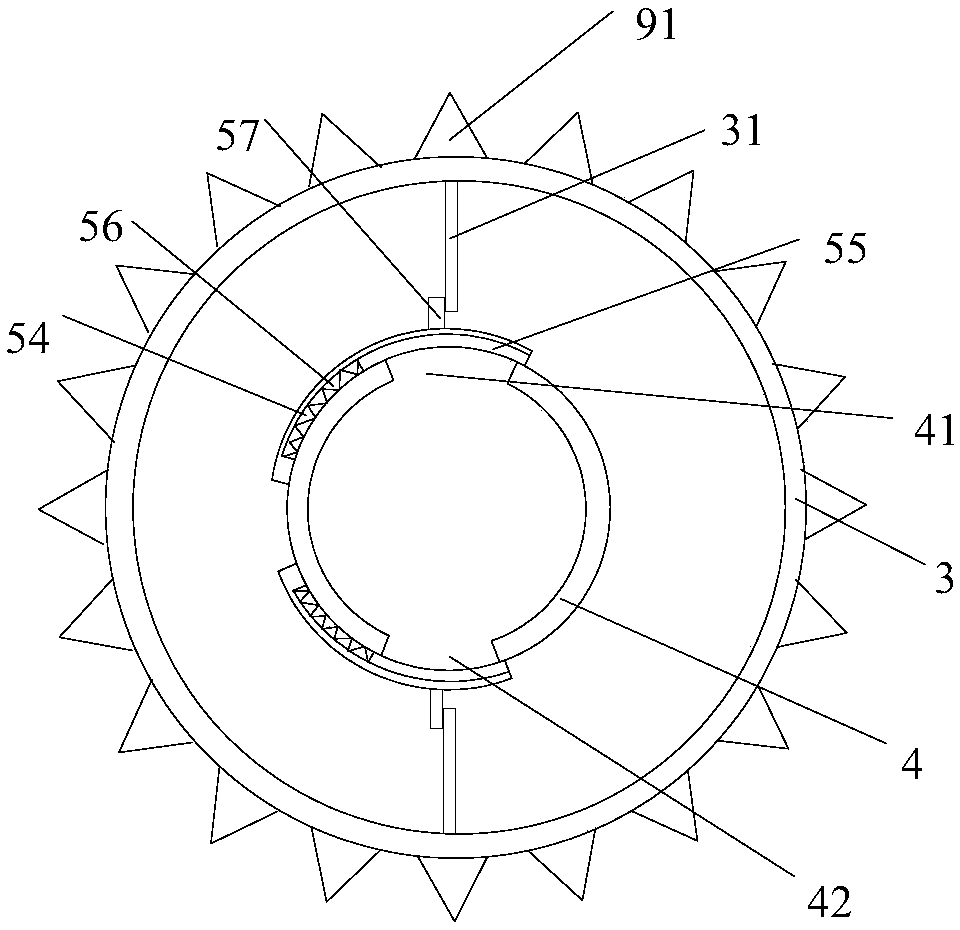

[0048] Such as Figure 3-5 A three-dimensional low-temperature baking device is shown, wherein the baking outer cylinder 3 is alternately rotated clockwise and counterclockwise, and the number of the sliding mechanisms 5 is two, and each sliding mechanism 5 includes a buffer inner cylinder 4. The slideway 54 arranged on the outer wall circumferentially and perpendicular to the central axis of the buffer inner cylinder 4, the sliding cover plate 55 pushed by the drive plate 31 that is slidably connected with the slideway 54, is arranged in the slideway 54 and connects the sliding cover plate 55 The elastic member 56 on the inner wall of the slideway 54 and the transmission block 57 vertically arranged on the outer surface of the sliding cover plate 55, the movement track of the sliding cover plate 55 covers the upper opening 41 or the lower opening 42 of the buffer inner cylinder 4, and the baking outer cylinder 3. The position of the inner wall corresponding to the transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com