VOCs organic waste gas treatment equipment

A technology for treating equipment and organic waste gas, applied in gas treatment, lighting and heating equipment, combustion methods, etc., can solve problems such as secondary pollution, high use cost, and large amount of residual volatile organic compounds, and achieve load reduction and prolongation The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

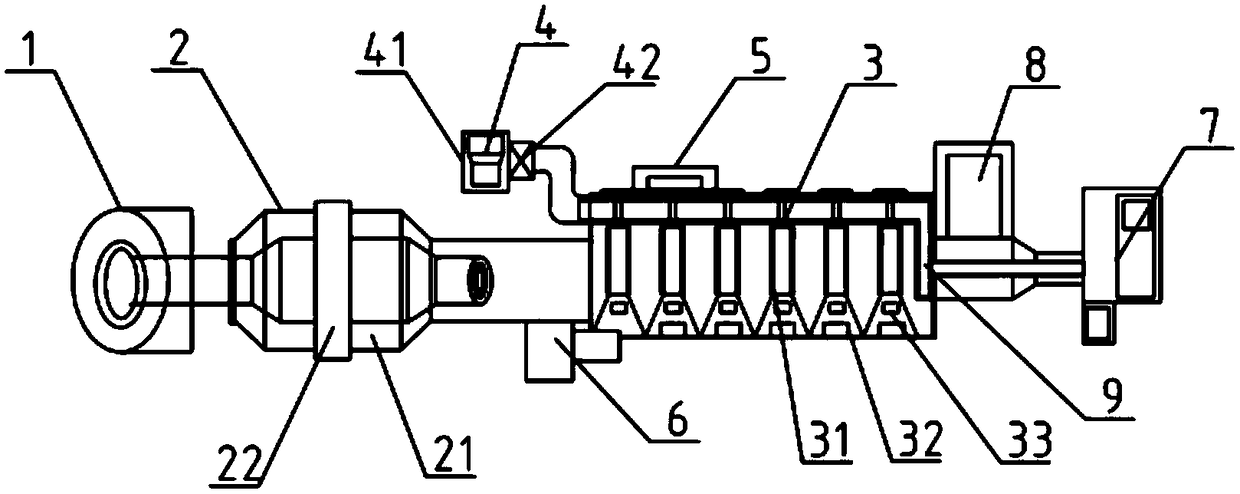

[0021] As attached figure 1 Attached figure 2 Shown

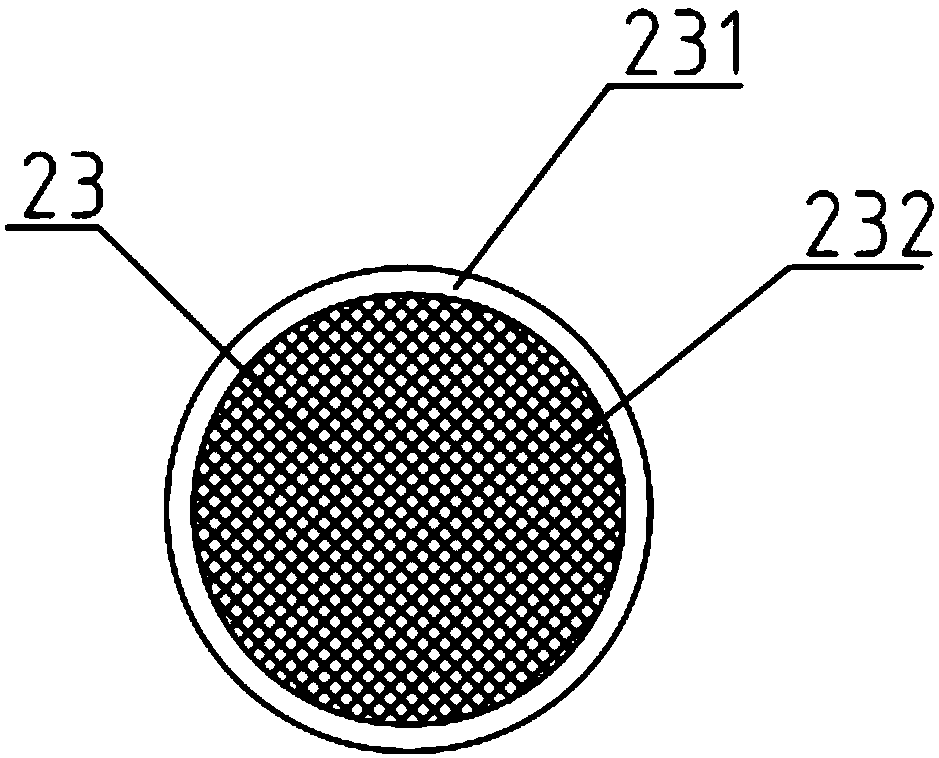

[0022] The present invention provides a VOCs organic waste gas treatment equipment, including a washing tower 1, a dry filter 2, a honeycomb activated carbon adsorption tower 3, a catalytic combustion furnace 4, a heat exchanger 5, an explosion-proof centrifugal fan 6, a chimney 7, and an electronic control system 8. And the exhaust pipe 9, the front end of the honeycomb activated carbon adsorption tower 3 is provided with a dry filter 2 for adsorbing coarse solid particles, and the front end of the dry filter 2 is provided with a washing tower 1 for drying exhaust gas; The upper end of the honeycomb activated carbon adsorption tower 3 is provided with an exhaust pipe 9 in the horizontal direction, and a catalytic combustion furnace 4 is provided at the upper end of the channel, and the catalytic combustion furnace 4 is connected with the heat exchanger 5; the end of the exhaust pipe 9 is provided with Chimney 7; the bottom ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap