Atomizing and spraying integrated dust remover

A technology of dust collector and spray nozzle, which is applied in the field of spray and spray integrated dust collector, which can solve the problems of unusable pipeline, great impact on personal safety and production safety, and influence on normal production, etc., and achieves simple structure, good dust removal effect and stability firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

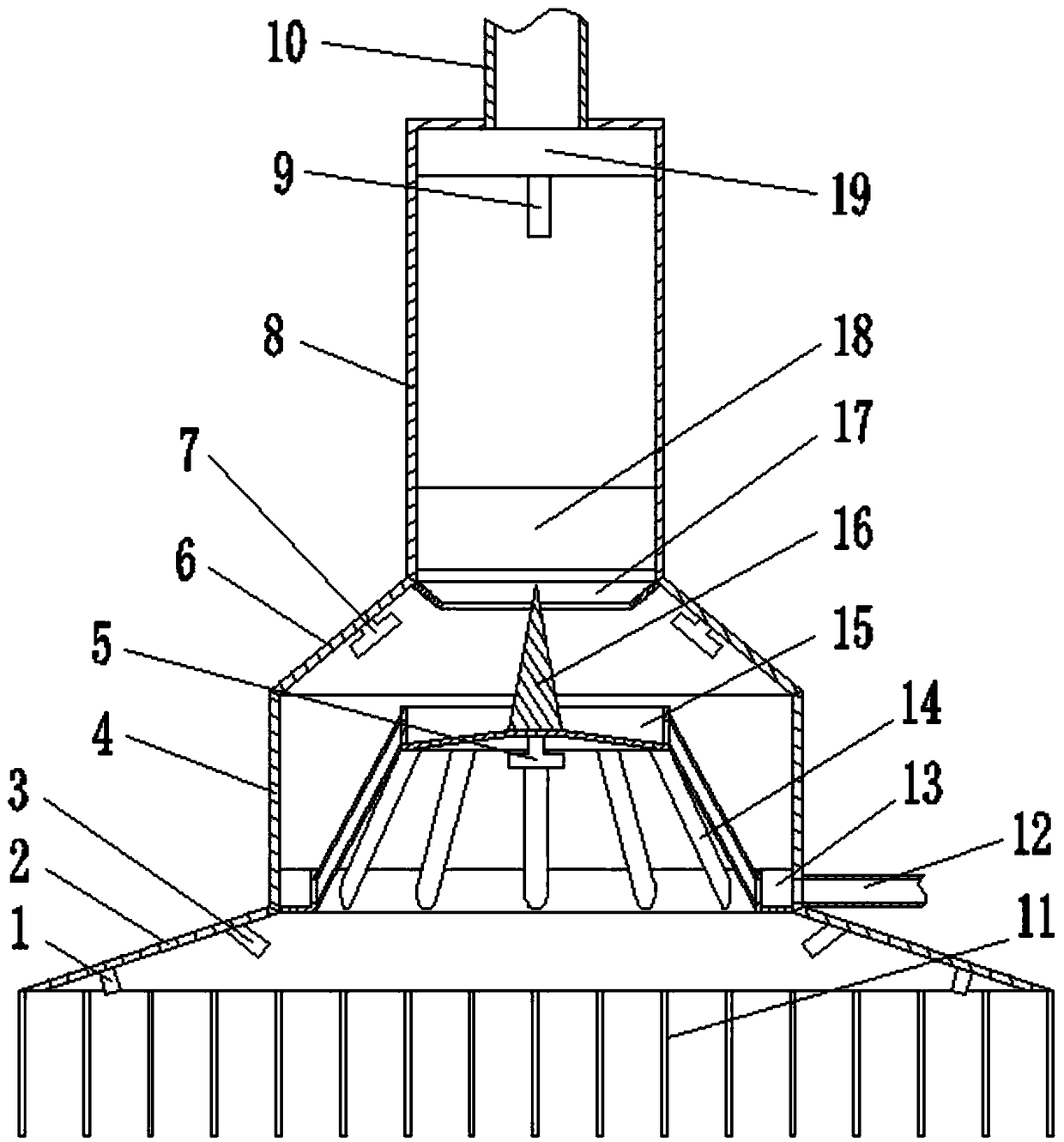

[0018] Below in conjunction with accompanying drawing, the present invention will be described in further detail, so that those skilled in the art can understand more clearly, as figure 1 Shown, the present invention adopts following scheme, comprises anti-escape spray nozzle 1, dust suction cover 2, dust catch spray nozzle 3, the first dust catch cover 4, the first dust catch rotary spray nozzle 5, the second dust catch cover 6, The second dust-catching rotary spray nozzle 7, the spray dust-catching cover 8 and the spray nozzle 9; Spray nozzle 1, a number of dust-collecting spray nozzles 3 are fixed on the inner wall of the dust collection cover 2 along the circumference; the opening edge of the upper end of the dust collection cover 2 extends upwards to form a first dust collection cover 4, The upper end edge extends obliquely upwards to form a second dust collection cover 6, and a number of second dust collection rotary spray nozzles 7 are fixed on the inner wall of the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com