Steel billet receiving bench

A material table and billet technology, applied in the field of iron and steel equipment, can solve the problems of deformation of the receiving plate, increase the use cost, and easily damage the internal structure of the tire frame, and achieve the effect of realizing energy conversion, reducing energy consumption and saving maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

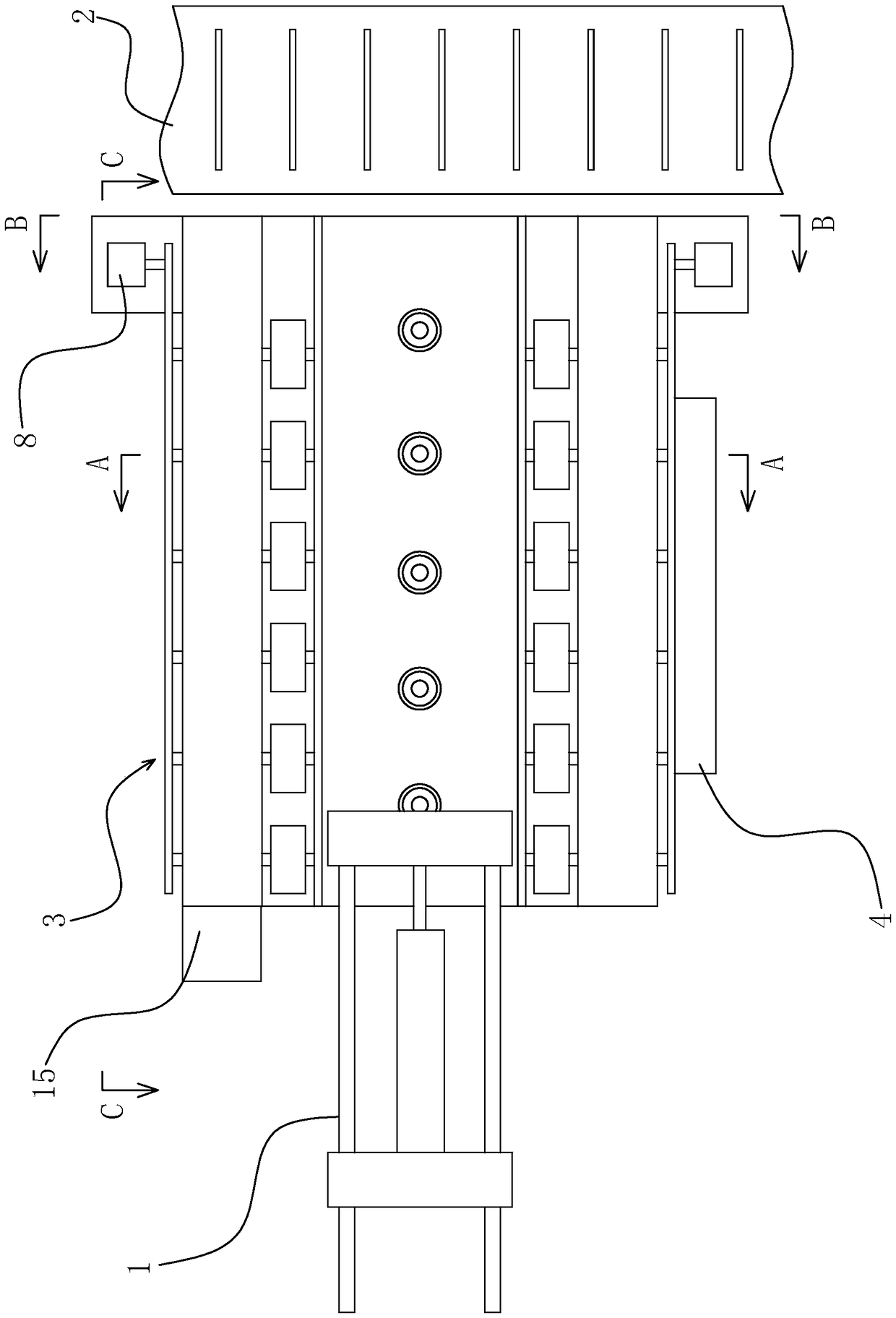

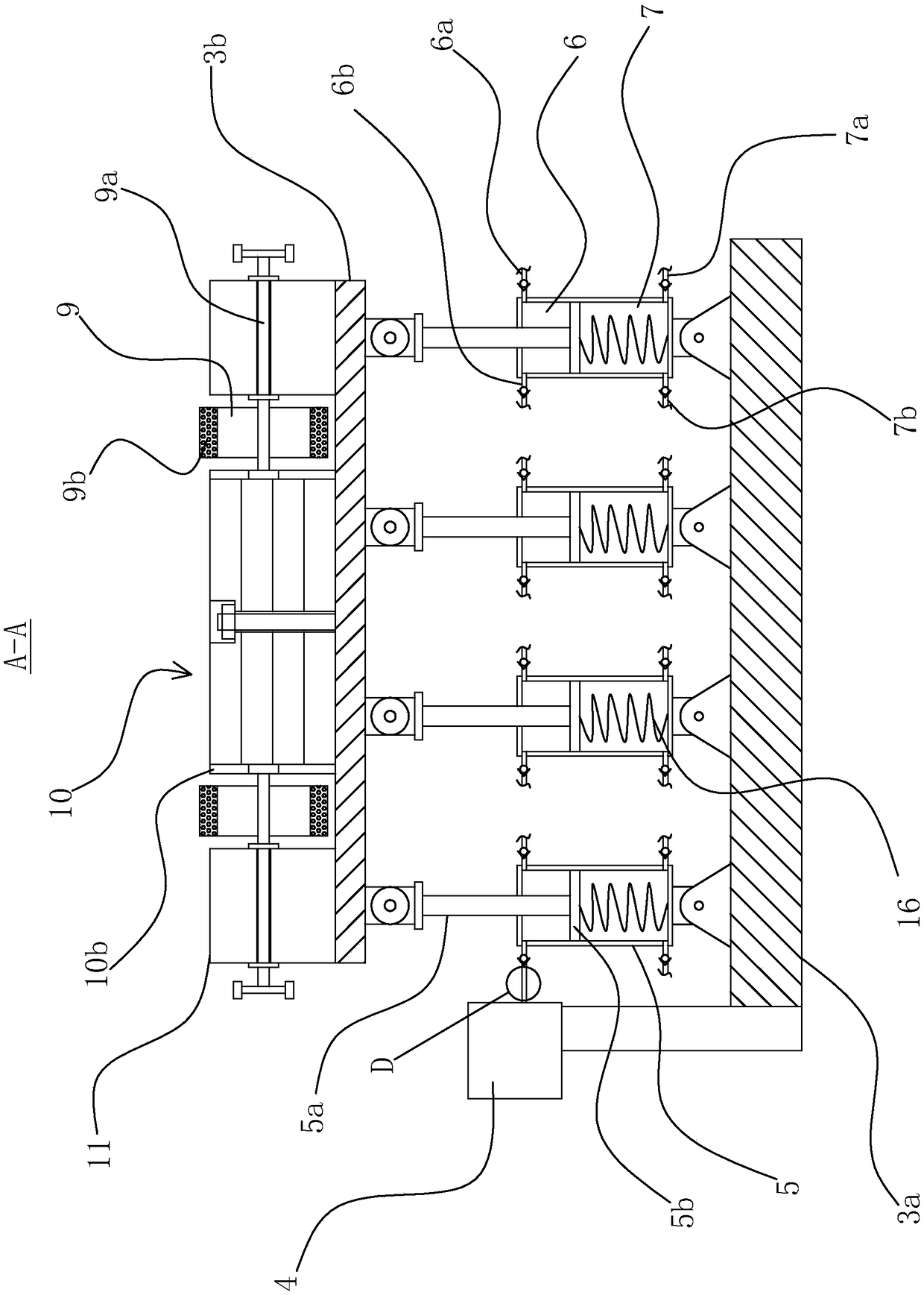

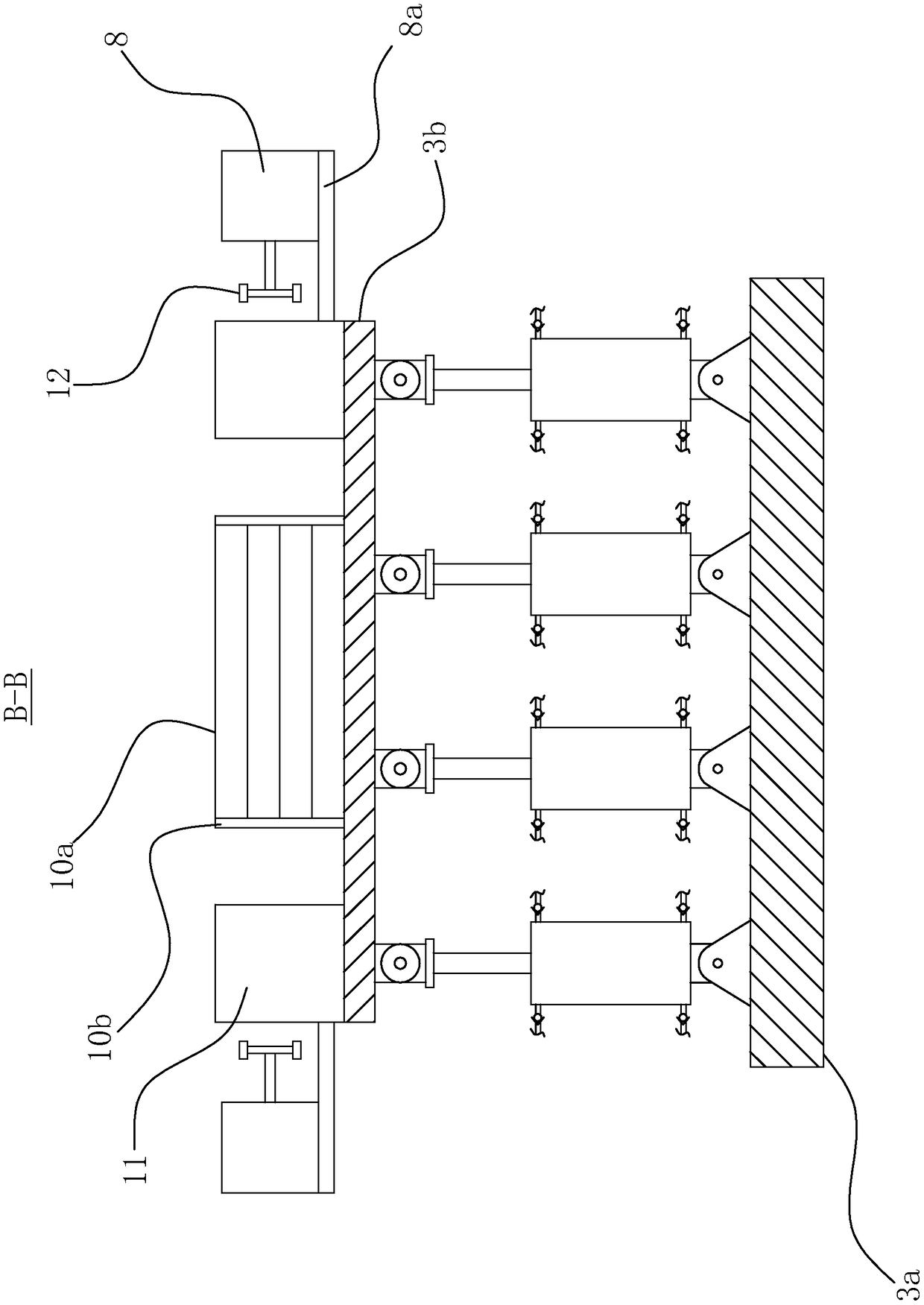

[0032] like Figures 1 to 5As shown, a steel billet receiving platform includes a tire frame body 3, and the tire frame body 3 includes an upper base 3b and a lower base 3a, and the upper side of the upper base 3b is provided with a material receiving block 10 and two support bases 11, the two support bases 11 are respectively located on the left and right sides of the upper base 3b, the upper side of the support base 11 is flush with the upper side of the receiving block 10, and the receiving block 10 Several rotating shafts 9a are rotated between the left side of the upper base 3b and the support base 11 on the left side of the upper base 3b, and a number of rotating shafts 9a are also rotated between the right side of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com