Pipe orifice machining device and machining method thereof

A processing device and processing method technology, applied in the field of flanging processing device, stainless steel pipe nozzle shrinkage, can solve problems such as easy to produce water leakage, affect product life and cost, unable to shrink and deform, avoid heat, prevent overheating and burning bad effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

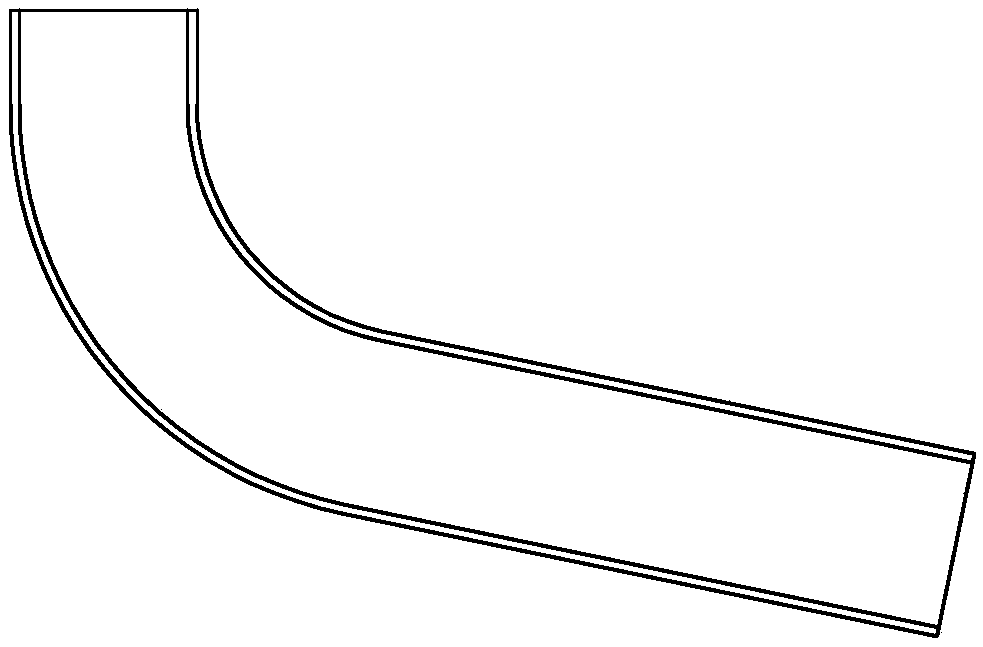

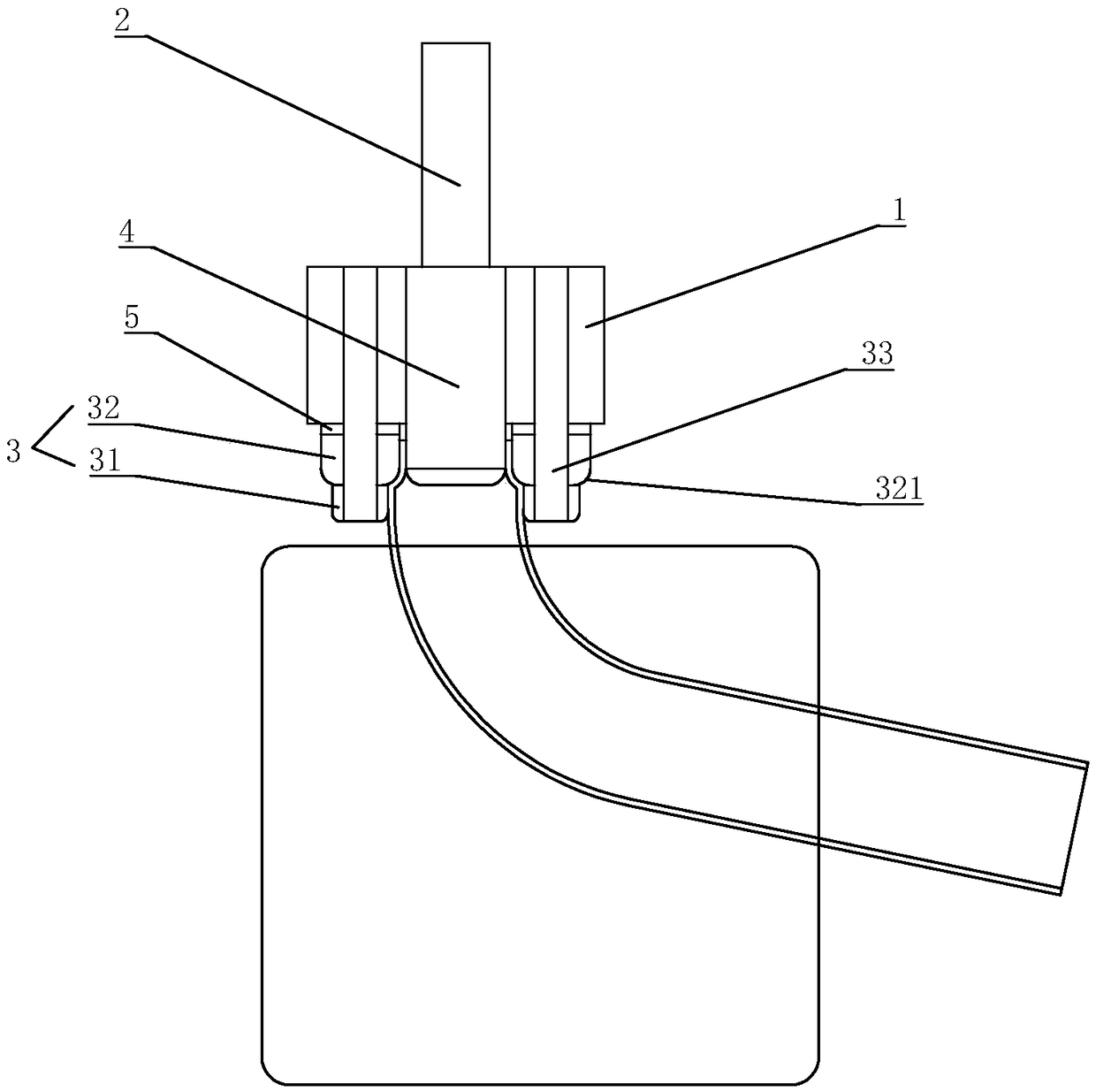

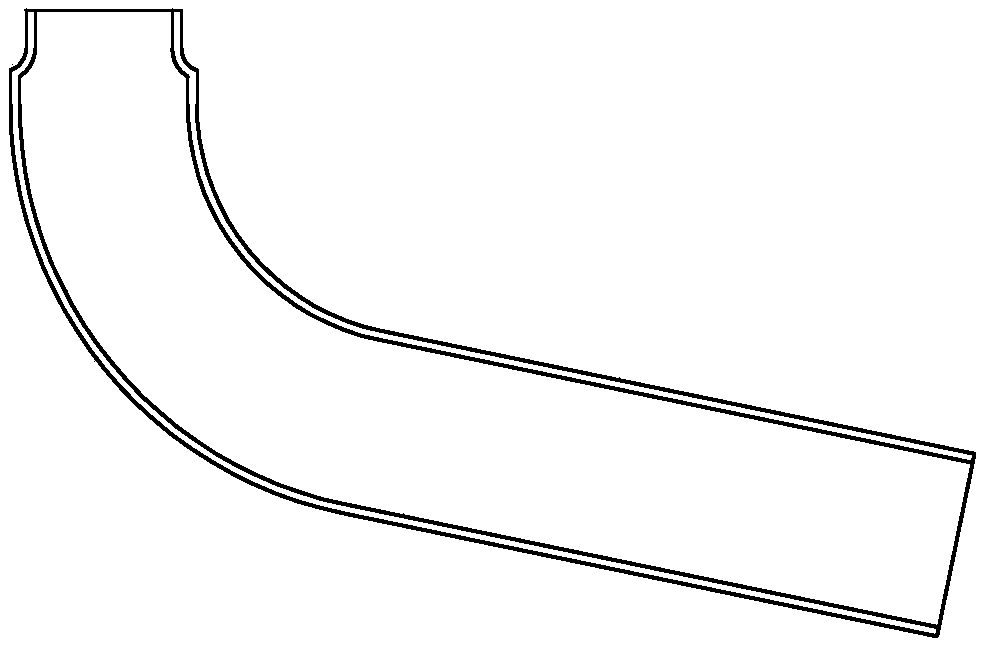

[0023] refer to Figure 1 to Figure 5 , a nozzle processing device of the present invention includes a rotary cutter, the rotary cutter includes a main cutter body 1, and a handle 2 is provided at one end of the main cutter body 1 to connect a driving device to drive the main cutter body 1 to rotate, so The other end of the main cutter body 1 is provided with a plurality of through holes around its rotation center, and a rotating shaft 33 is inserted in the through holes, and a working rotor 3 is installed on the rotating shaft 33 to rotate relatively; the working rotor 3 surrounds The center of rotation of the main cutter body 1 is evenly distributed in the circumferential direction, and the working rotor 3 and the main cutter body 1 are relatively rotatably connected, including a guide part and a forming part arranged above the guide part; the rotation center of the main cutter body 1 is fixed with an inner The rotating column 4 is further suitable for processing the nozzle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com