Vertical industrial silicon waste heat boiler with front membrane wall after-burning hearth

A waste heat boiler and membrane wall technology, which is applied in the field of industrial silicon waste heat boiler utilization equipment, can solve the problems of large fluctuations in flue gas volume, low power generation efficiency, and inconspicuous energy-saving benefits, etc., to reduce the inlet smoke temperature, prevent heat loss, Good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

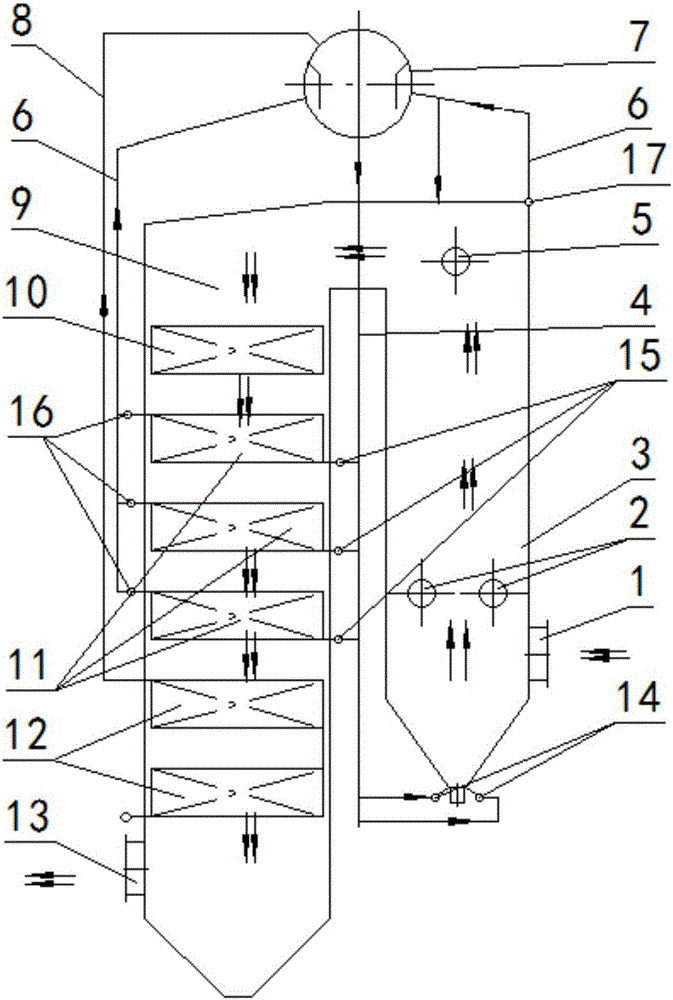

[0008] Such as figure 1 As shown, in this embodiment, a vertical industrial silicon waste heat boiler with a pre-film water-cooled wall supplementary combustion furnace includes a drum 7, a supplementary combustion furnace 3, a tail shaft flue 9, a downcomer 4, an outlet pipe 6, The water guide pipe 8; the tail shaft flue 9 are provided with a superheater 10, an evaporator 11, an economizer 12, an evaporator inlet header 15 and an evaporator outlet header 16 arranged on the evaporator 11 from top to bottom. Smoke outlet 13; supplementary combustion furnace 3 is provided with smoke inlet 1, methanol burner 2, explosion-proof door 5, membrane type wall header 14, membrane type wall header 17; described methanol burner 2 is located in On the side wall of the supplementary combustion furnace 3 and located above the smoke inlet 1, the explosion-proof door 5 is arranged on and above the supplementary combustion furnace 3; one end of the downcomer 4 is connected to the drum 7, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com