Assembly method and device for LED box

A technology for LED cabinets and assembly devices, which is applied in assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as site confusion, high personnel intensity, and damage to modules, so as to improve quality, improve production efficiency, The effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

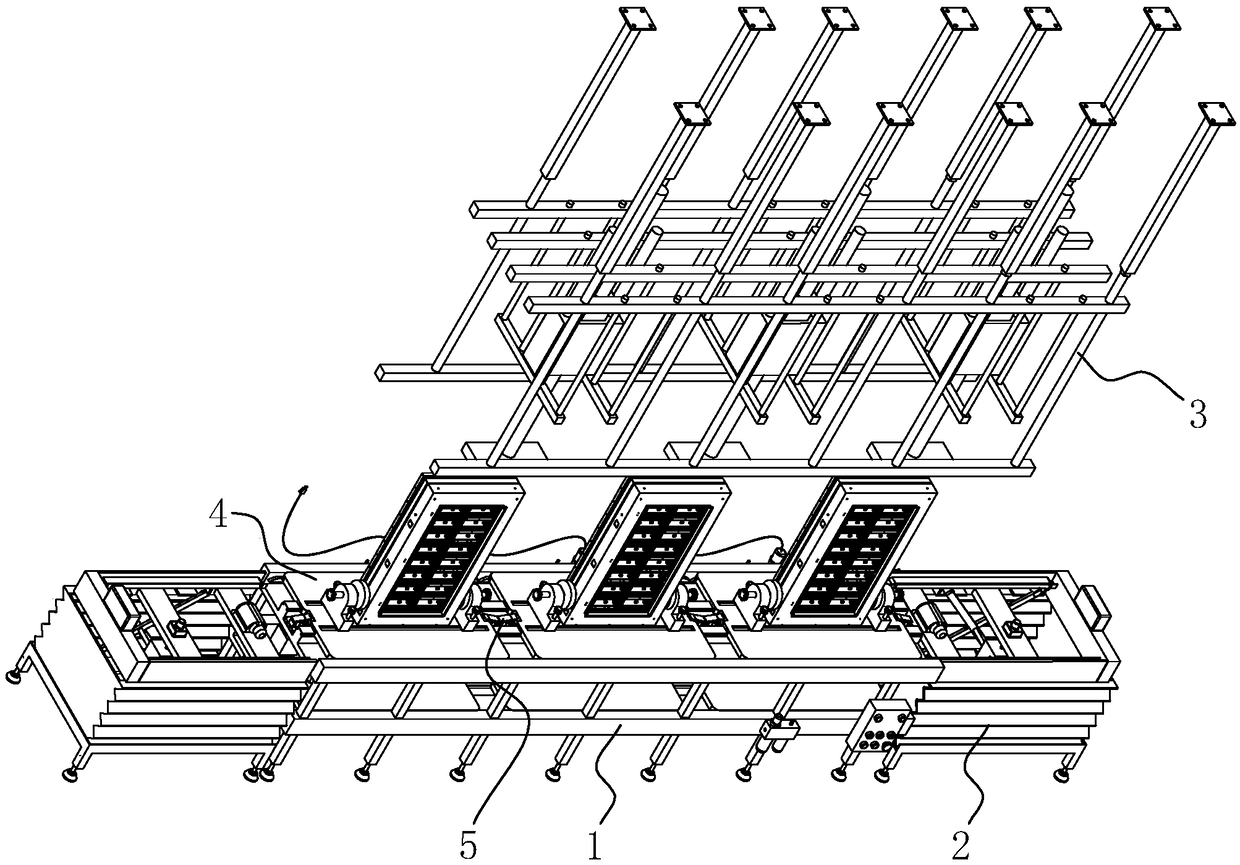

[0055] Embodiment 1: a kind of LED box assembly device, such as figure 1 As shown, it includes a transmission device 1 , an automatic pressing mechanism 3 , an automatic clamping mechanism 5 , a lifting mechanism 2 and a pallet 4 .

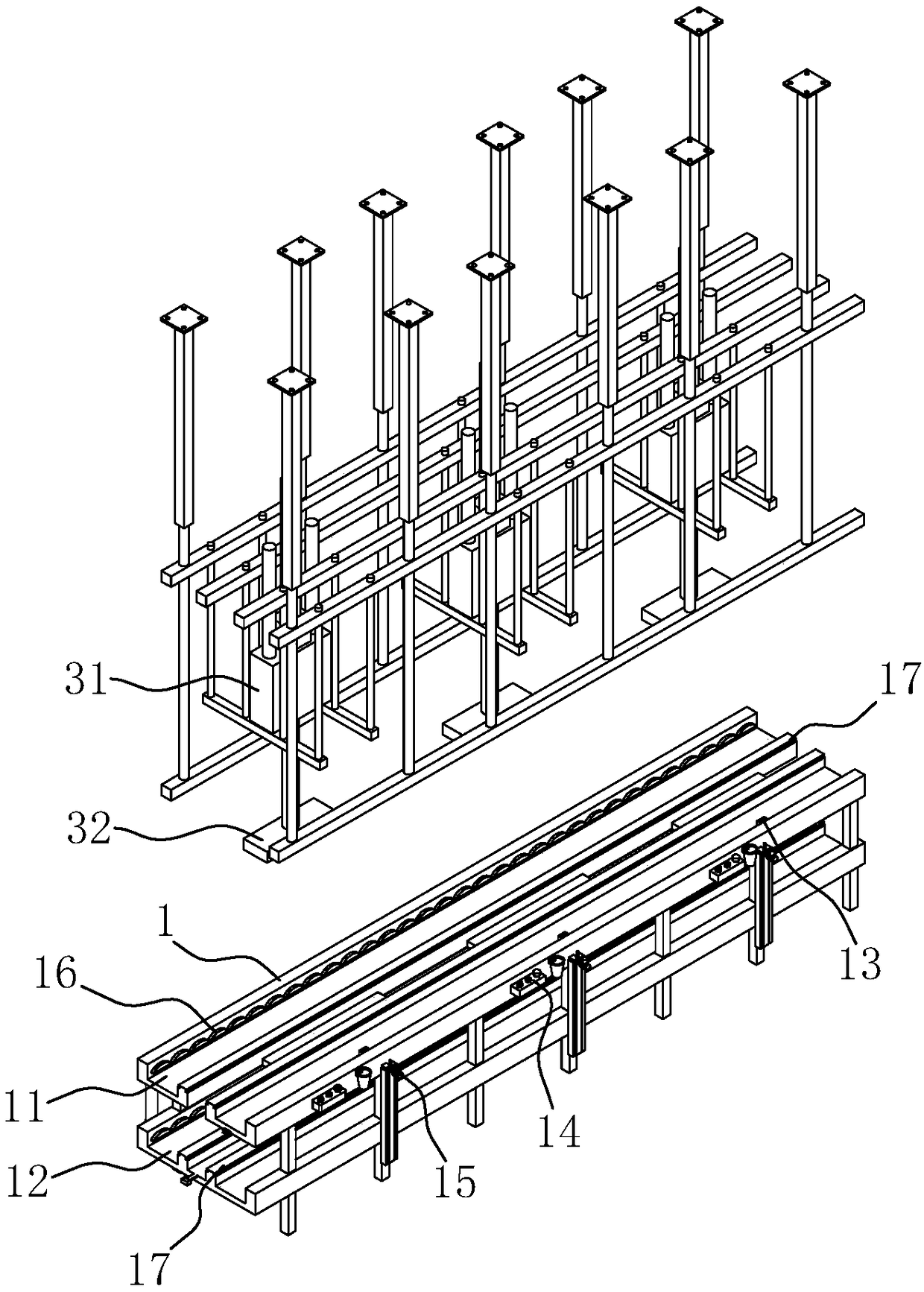

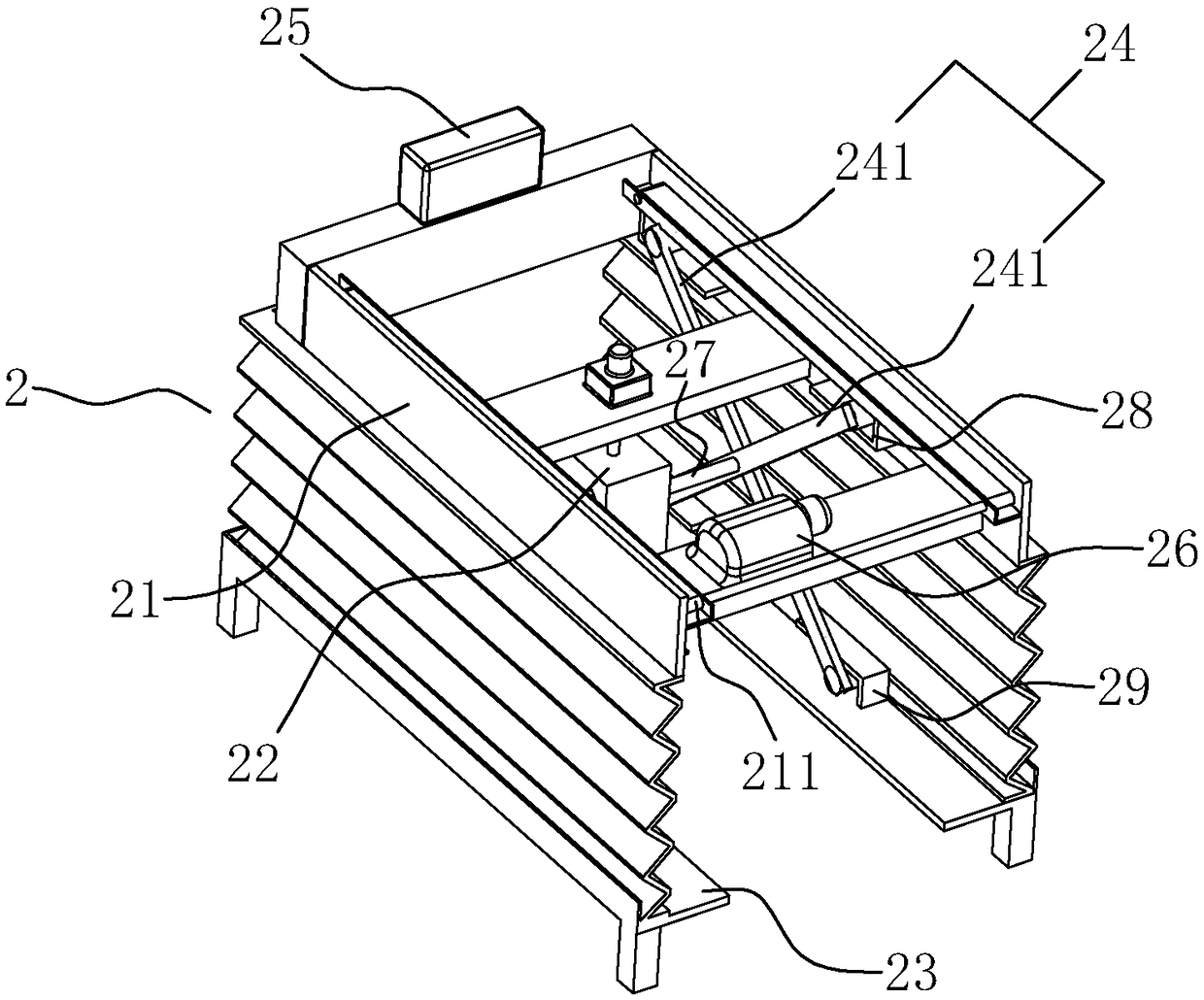

[0056] refer to figure 2 , The transmission device 1 is provided with upper and lower slideways, both of which can slide on the tray 4 . Such as figure 1 As shown, there are two lifting mechanisms 2, which are respectively arranged at the two ends of the transmission device 1, combined with the attached image 3 , the lifting device is provided with a conveyor belt and a lifting cylinder 22, and the lifting cylinder 22 is used to control the lifting of the conveyor belt. Wherein, when the conveyor belt rises to the top, it is connected with the upper slideway 11 on the transmission device 1 , and when the conveyor belt descends to the bottom, it is connected with the glideway 12 on the transmission device 1 .

[0057] The pallet 4 sent out fr...

Embodiment 2

[0076] Embodiment 2: A method for assembling an LED box, comprising:

[0077] S1. Inspection, check whether the electricity, gas and various mechanisms on the assembly device are normal;

[0078] S2, installation, after the detection is normal, the box body frame is placed on the pallet 4 on one of the lifting mechanisms 2, wherein, the lifting mechanism 2 is the initial position, and the clamping handle 412 is adjusted to make the two clamping parts 411 hold the box body frame fixed;

[0079] S3, transport to the station, after the installation is completed, start the motor 26 to pass the tray 4 into the upper slideway 11, after passing through the first sensor 13, the first group of automatic pressing mechanism 3 on the path starts, and the tray 4 on it starts The two stoppers 51 are raised, and when the tray 4 reaches the predetermined position, the stopper 51 abutting against the bottom of the tray 4 pushes out of the plane where the bottom of the tray 4 is under the acti...

Embodiment 3

[0085] Embodiment 3: as Figure 7 As shown, the difference from Embodiment 1 is that the limiting device 51 is an elastic telescopic rod 53 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap