Improved protective cover of digitalized vertical lathe

A vertical lathe, an improved technology, is used in maintenance and safety accessories, metal processing equipment, metal processing machinery parts, etc., and can solve the problems of high temperature during lathe processing, difficult cleaning of protective cover dust, and poor shock absorption effect. , to achieve the effect of stable lathe installation, increased ventilation and heat dissipation, and reduced vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

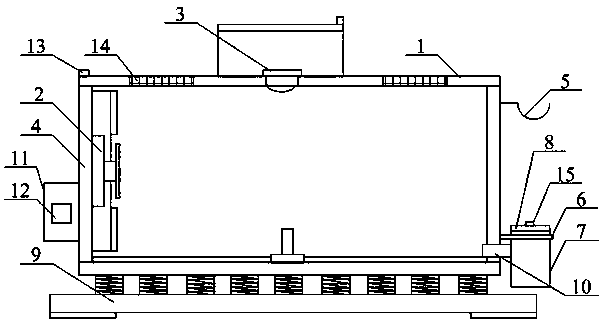

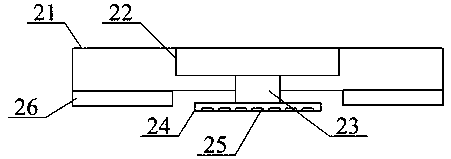

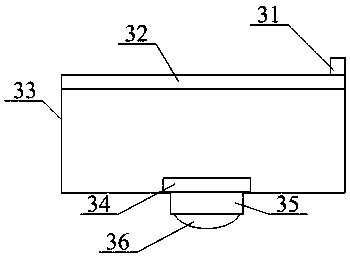

[0040] as attached figure 1 to attach Figure 4 shown

[0041] The invention provides an improved protective cover for a digital vertical lathe, which includes an upper plate 1, a cooling machine structure 2, a cleaning nozzle structure 3, a side plate 4, a hook 5, an open ring 6, a waste water bucket 7, and a bucket Cover 8, shock-absorbing spring plate structure 9, waste water pipe 10, storage box 11, box opening 12, switch 13, breathable mesh 14 and handle 15, the left and right sides of the lower part of the upper plate 1 are respectively bolted to the side plate 4 The upper part; the left side of the cooling machine structure 2 is connected to the right side of the side plate 4 provided on the left side; the lower part of the cleaning spray head structure 3 is connected to the upper middle position of the upper plate 1; The middle position of the lower part of the water head structure 3 runs through the lower middle position of the upper plate 1; the lower part of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com