Overhead valve control device of water mist abrasive mixing cylinder

A technology of control device and mixing cylinder, which is applied in the direction of abrasive material feeding device, used abrasive processing device, abrasive material, etc. It can solve the problems of difficult addition of abrasive material, potential safety hazards, manual opening and closing, etc., and achieves reasonable structure, Good sealing, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

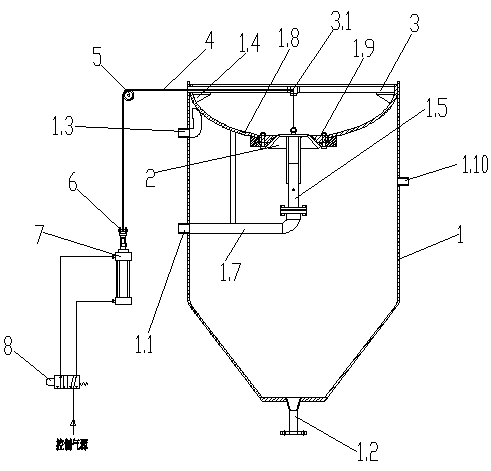

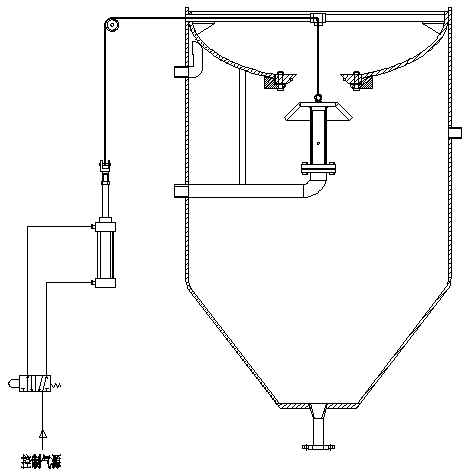

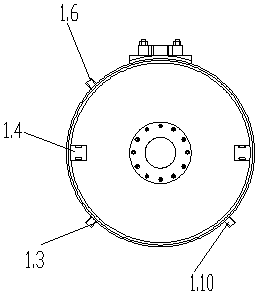

[0021] see Figure 1 to Figure 3 , the present invention is a top valve control device for a water mist abrasive mixing cylinder, comprising a water mist abrasive cylinder body 1, a stainless steel wire 4, a guide pulley 5 and a pneumatic traction telescopic cylinder 7, the top of the water mist abrasive cylinder body 1 is provided with There is a head 1.8, the head 1.8 is reversed, and the two ends of the head 1.8 are symmetrically provided with positioning bracket ear seats 1.4, and the mushroom head positioning bracket 3 is placed on the ear seat 1.4 of the positioning bracket, and the mushroom head is positioned The bracket 3 is a hollow steel pipe, the mushroom head positioning bracket 3 is hinged with the guide pin 3.1, and the guide pin 3.1 is located in the middle of the mushroom head positioning bracket 3;

[0022] The air inlet and the air outlet of the pneumatic traction telescopic cylinder 7 are connected to the air valve 8, the telescopic rod of the pneumatic trac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com