Die cutting method for adhesive product

A technology for sticking products and products, which is applied in the field of die-cutting of glued products, can solve the problems of user waste and increase production costs, and achieve the effect of reducing enterprise costs and improving material utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

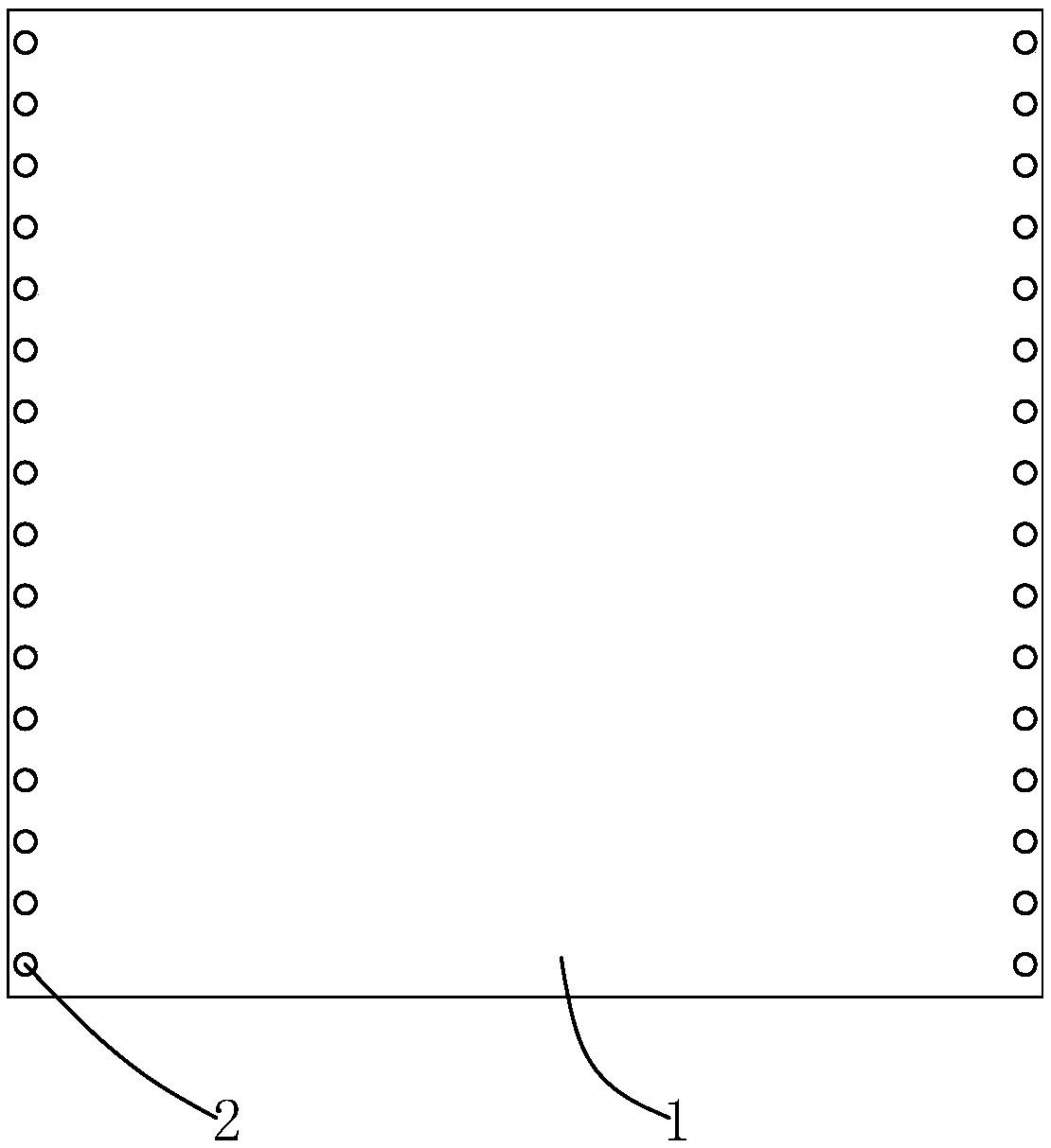

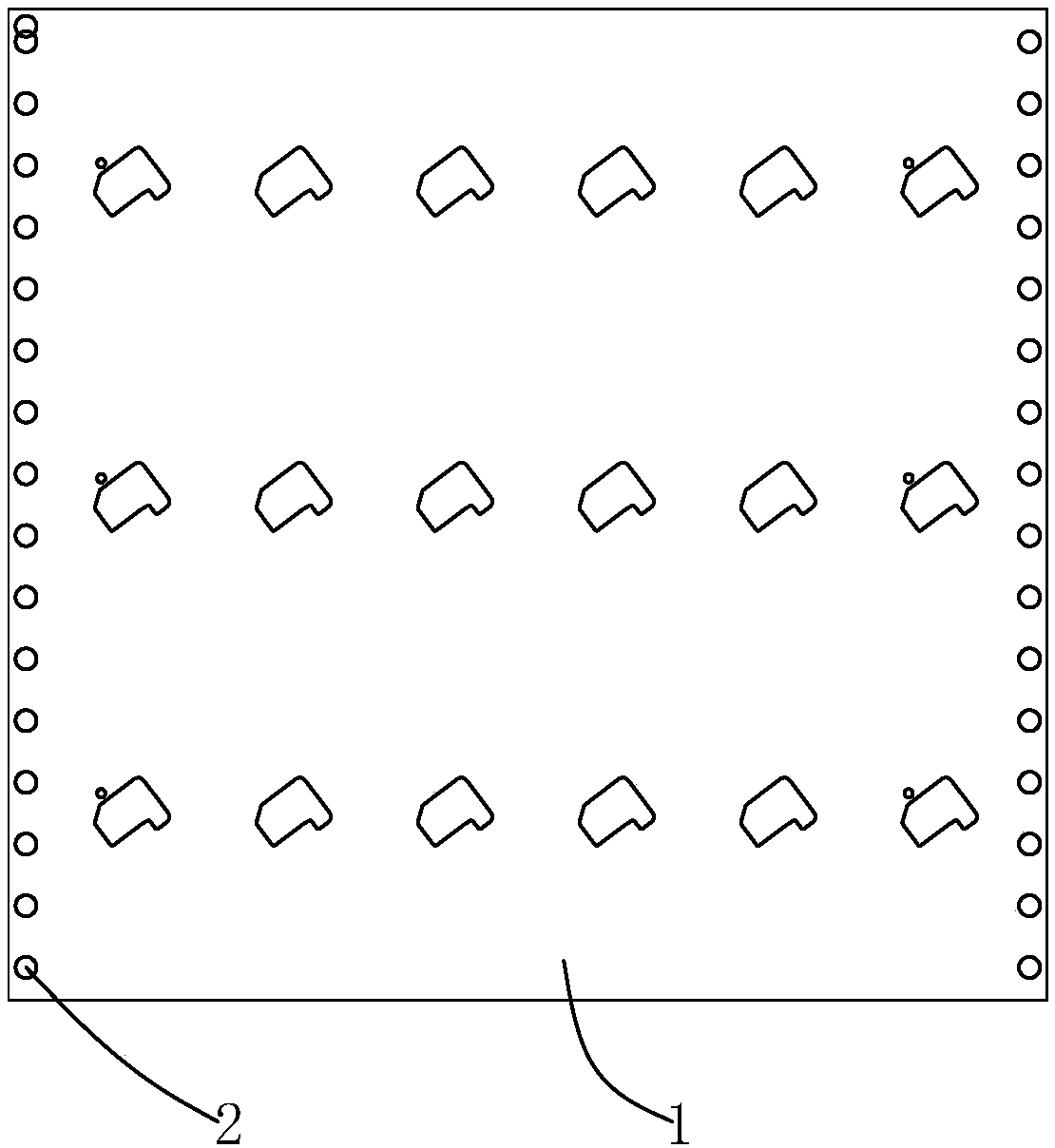

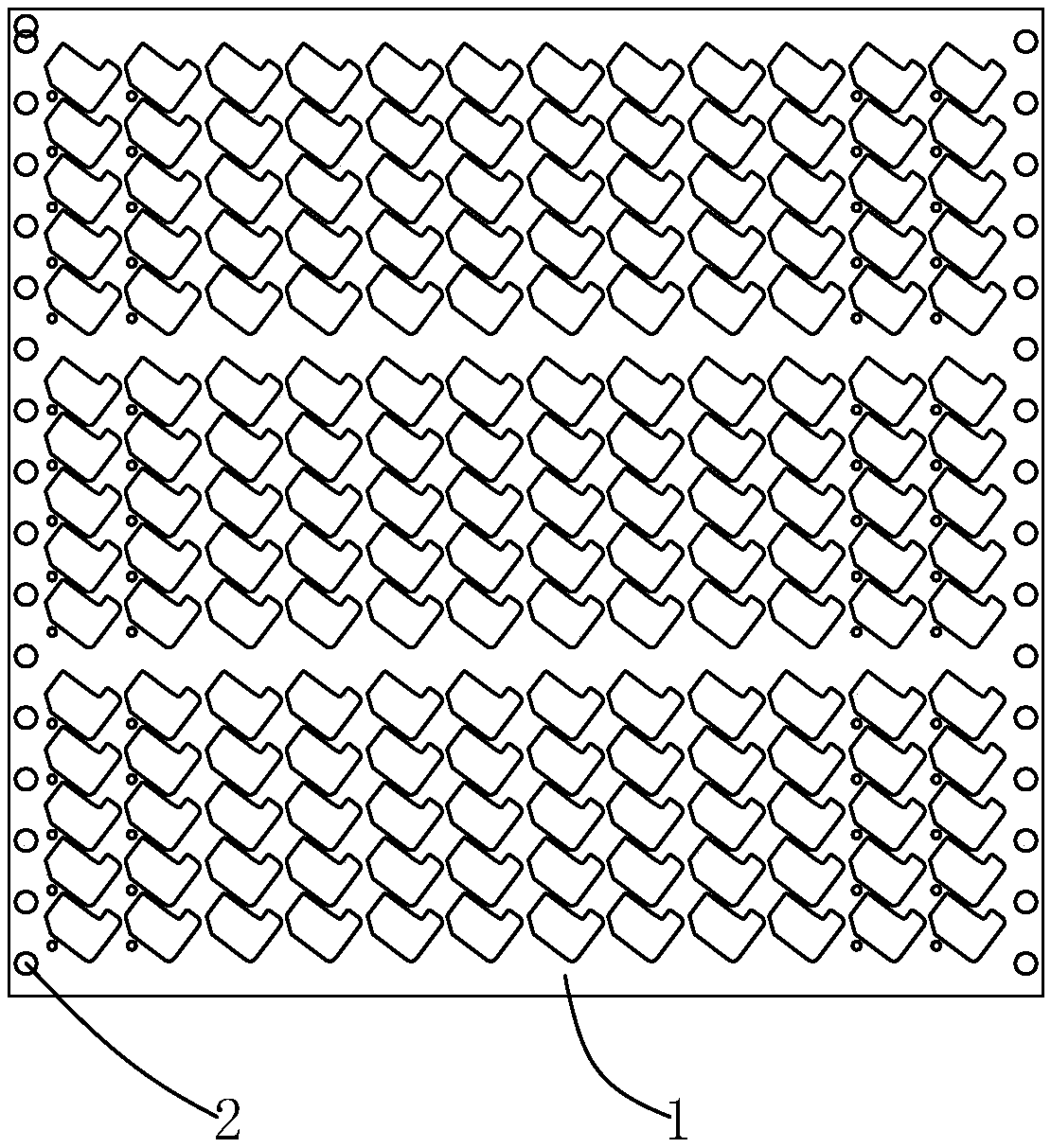

[0018] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment: According to Figure 1 to Figure 3 A die-cutting method of an adhesive product shown is provided with an adhesive product 1 and a punch press for die-cutting the adhesive product 1, and a mold is also arranged on the punch press, and the adhesive product 1 is formed by a bottom Die, adhesive layer, and upper die, the die-cutting steps are as follows:

[0019] (1), the mold is fixed on the punch, and then the adhesive product 1 is placed on the mold;

[0020] (2), start the punching machine, first be provided with a plurality of auxiliary positioning holes 2 on the base mold of the adhesive product 1 by the punching machine and the mold;

[0021] (3) Then, the adhesive product 1 can be punched several times according to the auxiliary positioning hole 2 .

[0022] In order to increase the punching effect, further, the punching machine is a four-column pun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com