Wooden desk processing device

A technology for processing equipment and desks, applied in the field of wooden desk processing equipment, can solve the problems of reducing the negative pressure force, weakening the negative pressure effect, unable to achieve effective processing of wood chips, etc., to reduce precision requirements, ensure smooth movement, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

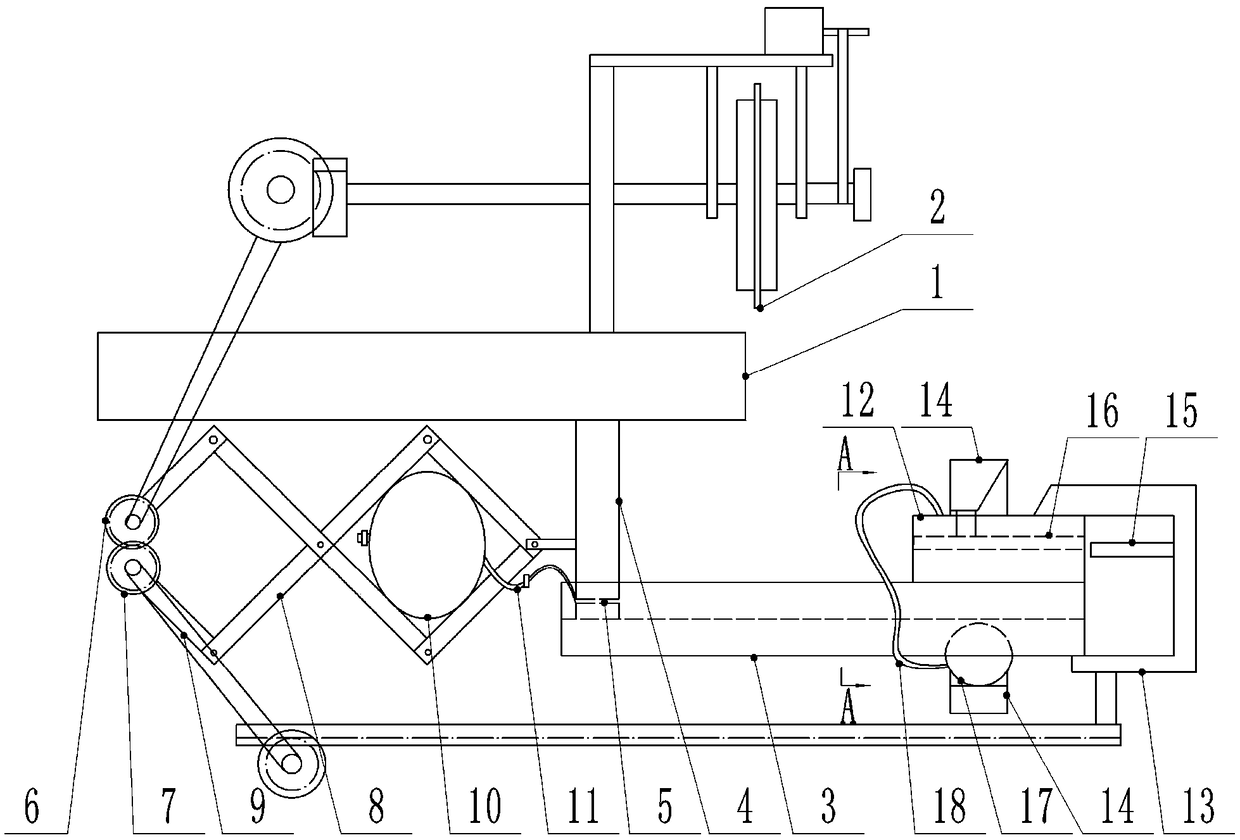

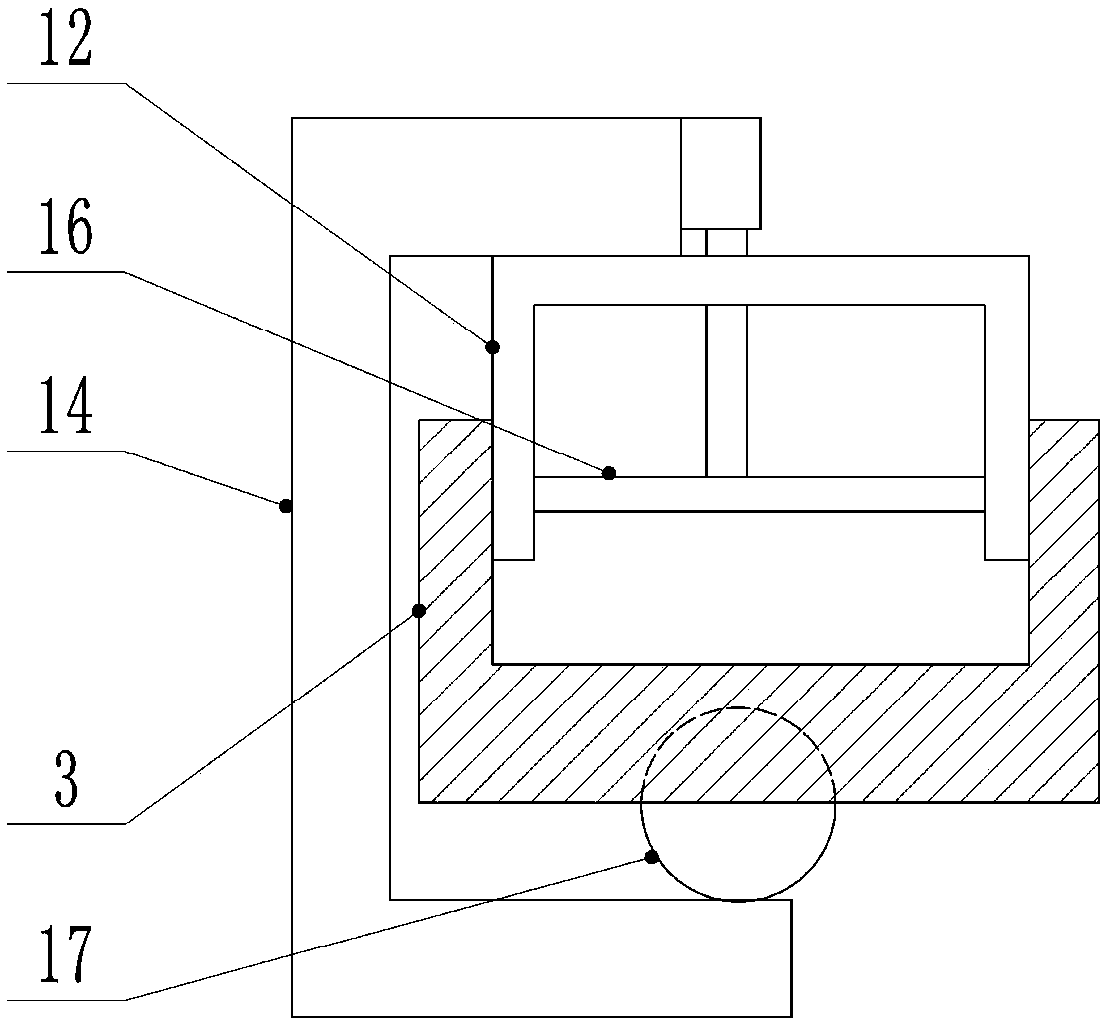

[0018] The reference signs in the accompanying drawings of the description include: cutting table 1, cutter wheel 2, collecting tank 3, push plate 4, blowing hole 5, main gear 6, slave gear 7, changing frame 8, connecting rod 9, balloon 10, One-way air outlet pipe 11, cover plate 12, buckle plate 13, clamping plate 14, inserting rod 15, pressing plate 16, capsule body 17, one-way glue spraying pipe 18.

[0019] Example figure 1 Shown: a wooden desk processing equipment, including a cutting mechanism, a collection mechanism, a cleaning mechanism, an extrusion mechanism and a transmission mechanism.

[0020] The cutting mechanism is used to cut wood, and the structure includes a cutting table 1, a knife rest is arranged directly above the end of the cutting table 1, and the knife rest is slidably arranged on the cutting table 1, and the specific sliding connection between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com