High-speed train wheel vibration absorbing device based on photonic crystals

A technology of phononic crystals and train wheels, which is applied to wheels, wheels, and vehicle parts characterized by rail running parts, can solve problems such as the influence of the band gap characteristics of phononic crystals, achieve simple structure, improve vibration absorption capacity, and facilitate The effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

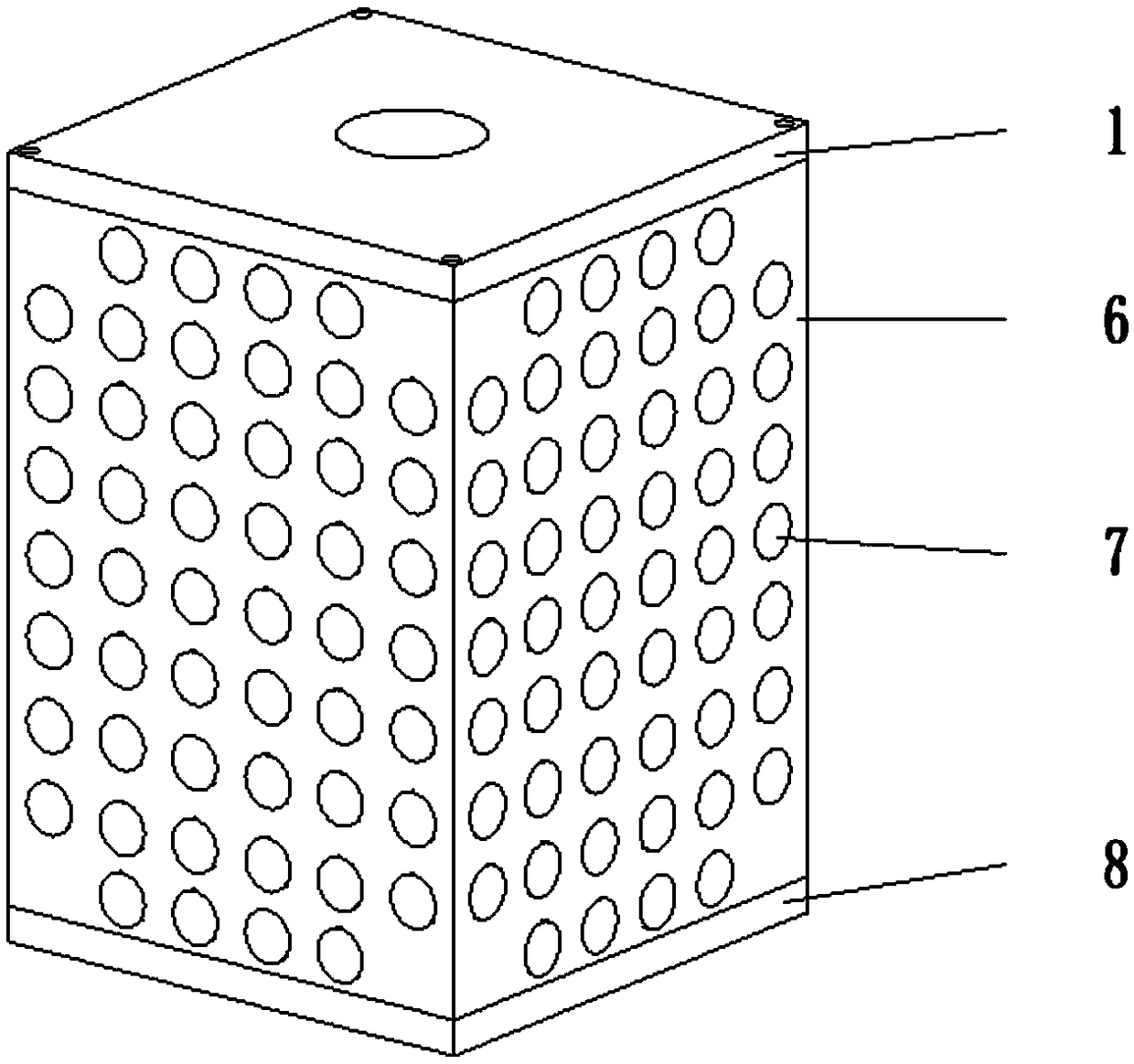

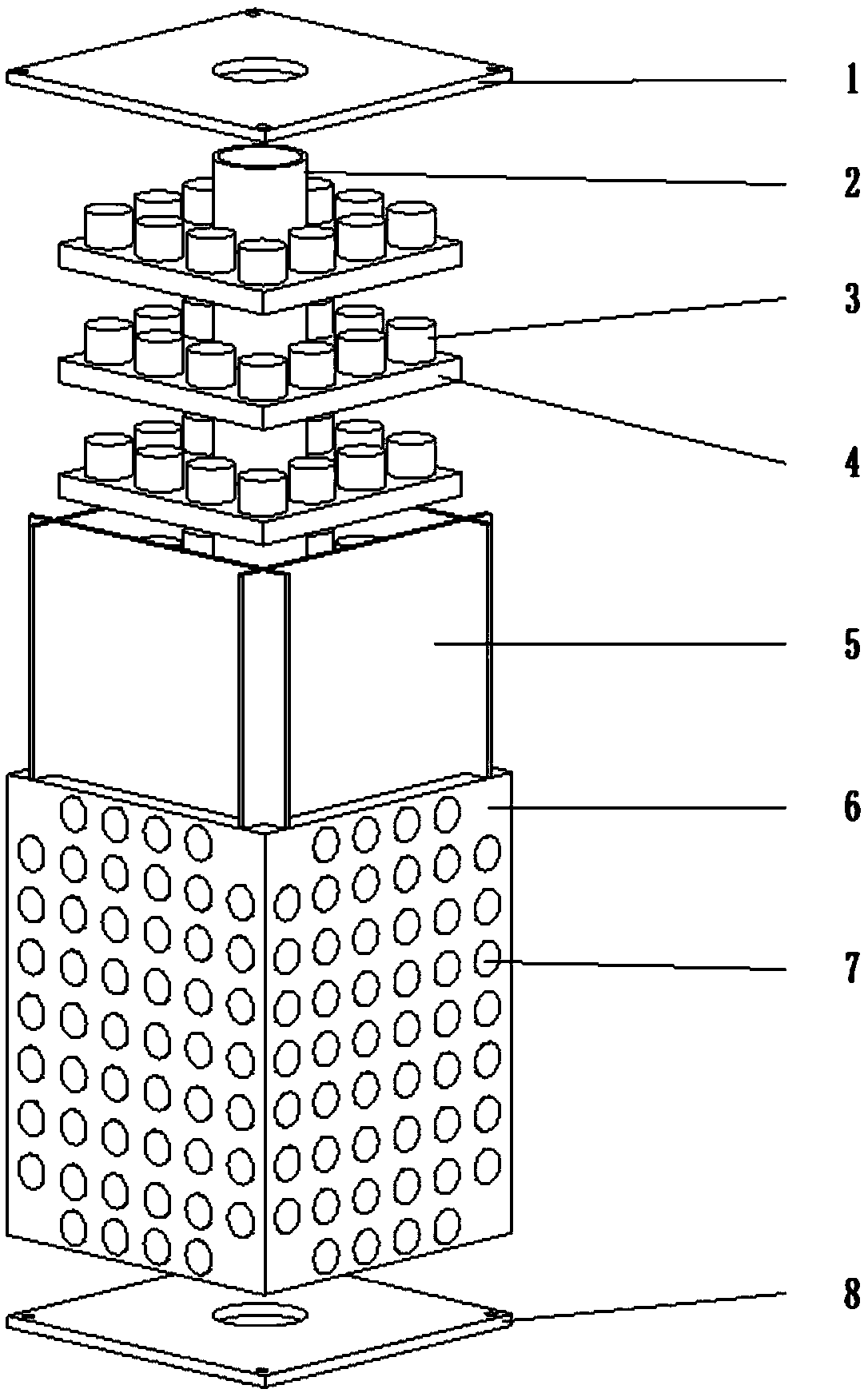

[0031] Specific implementation mode one: combine Figure 1-Figure 2 Explain that a high-speed railway train wheel vibration absorber based on phononic crystals in this embodiment includes an upper cover plate 1, a lower cover plate 8, a vibration transmission rod 2, and “point defect” localized phononic crystal vibration absorbing components 6 and 7 , Bragger-type phononic crystal vibration-absorbing component 3 , vibration-isolation cushion layer 4 , buffer layer 5 .

[0032] Among them, the "point defect" localized phononic crystal vibration-absorbing component includes a square sleeve 6 and a plurality of scatterers 7, and the plurality of scatterers 4 are evenly distributed and fixed in circular holes on the square sleeve.

[0033] Among them, the Bragger-type phononic crystal vibration-absorbing component 3 includes a circular cylinder and a plurality of scatterers, and the plurality of scatterers are evenly distributed and fixed in the circular holes on the cylinder,

...

specific Embodiment approach 2

[0052] The assembly process of the high-speed train wheel vibration absorber based on phononic crystals is as follows:

[0053] (1) Hollow round holes are processed on the vibration isolation cushion, and they are connected in series by vibration transmission rods.

[0054] (2) The upper cover and the lower cover are respectively processed with threaded holes, the two ends of the vibration transmission rod are processed with threads matching the upper and lower cover, and the vibration transmission rod is fixed on the upper and lower cover.

[0055] (3) Grooves are processed on the buffer layer, and the vibration isolation pad is embedded in the grooves.

[0056] (4) Use triangular steel to fix the rubber buffer plate on the upper and lower cover plates.

[0057] (5) Use screws to respectively fix the upper cover and the lower cover on the square sleeve to complete the assembly.

[0058] The following factors should be considered in actual use:

[0059] 1. The period number...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com