Ultraprecise electrohydraulic servocontrol static-pressure linear slide way

A technology of servo control and linear guide rail, which is applied in the direction of manufacturing tools, large fixed members, metal processing machinery parts, etc. It can solve the problems of low anti-eccentric load rigidity, hydraulic oil heating, high cost of use, etc., and achieve small friction coefficient and high speed , The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are exemplified, and the ultra-precision electro-hydraulic servo-controlled static pressure linear guide of the present invention is described in detail as follows:

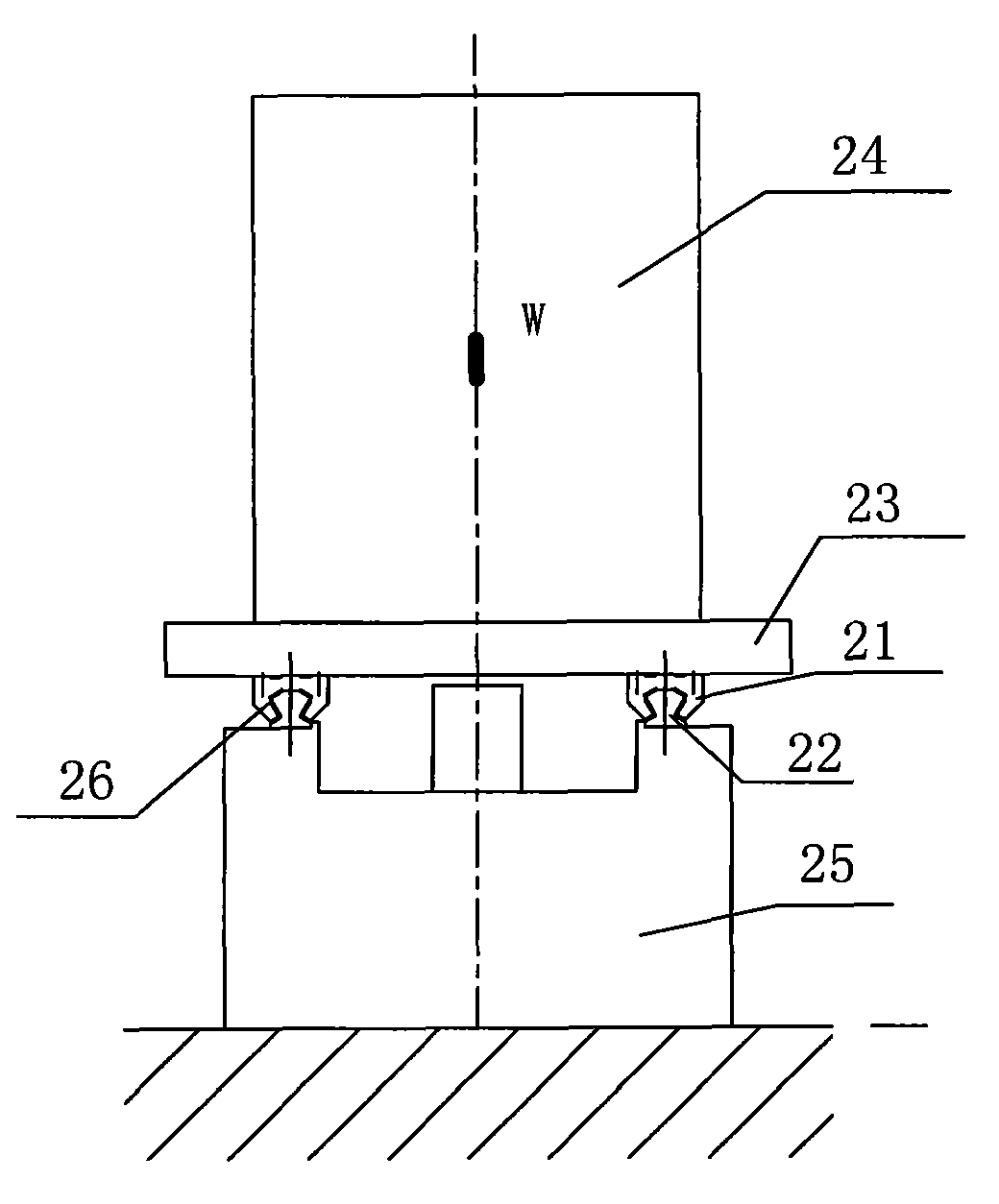

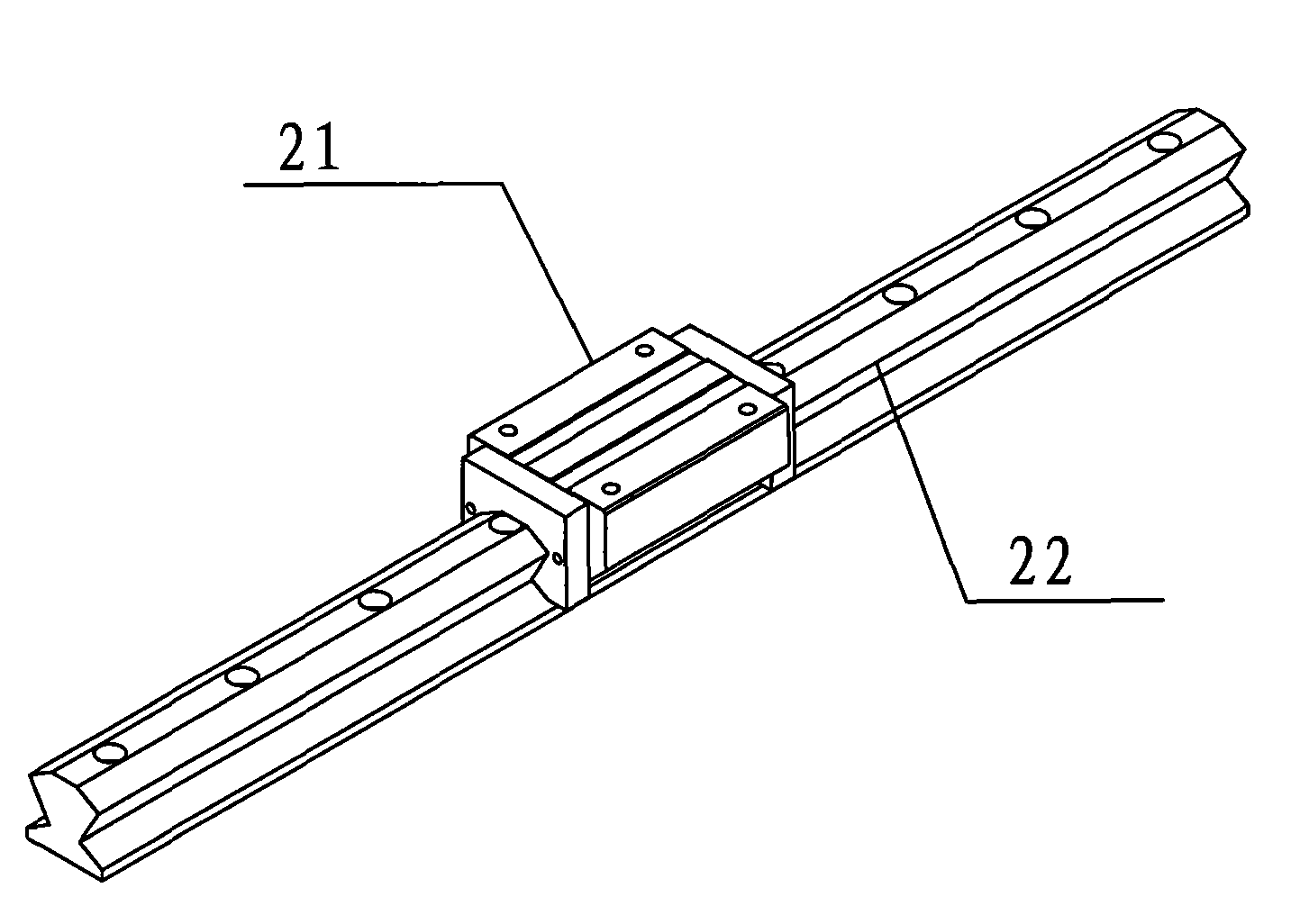

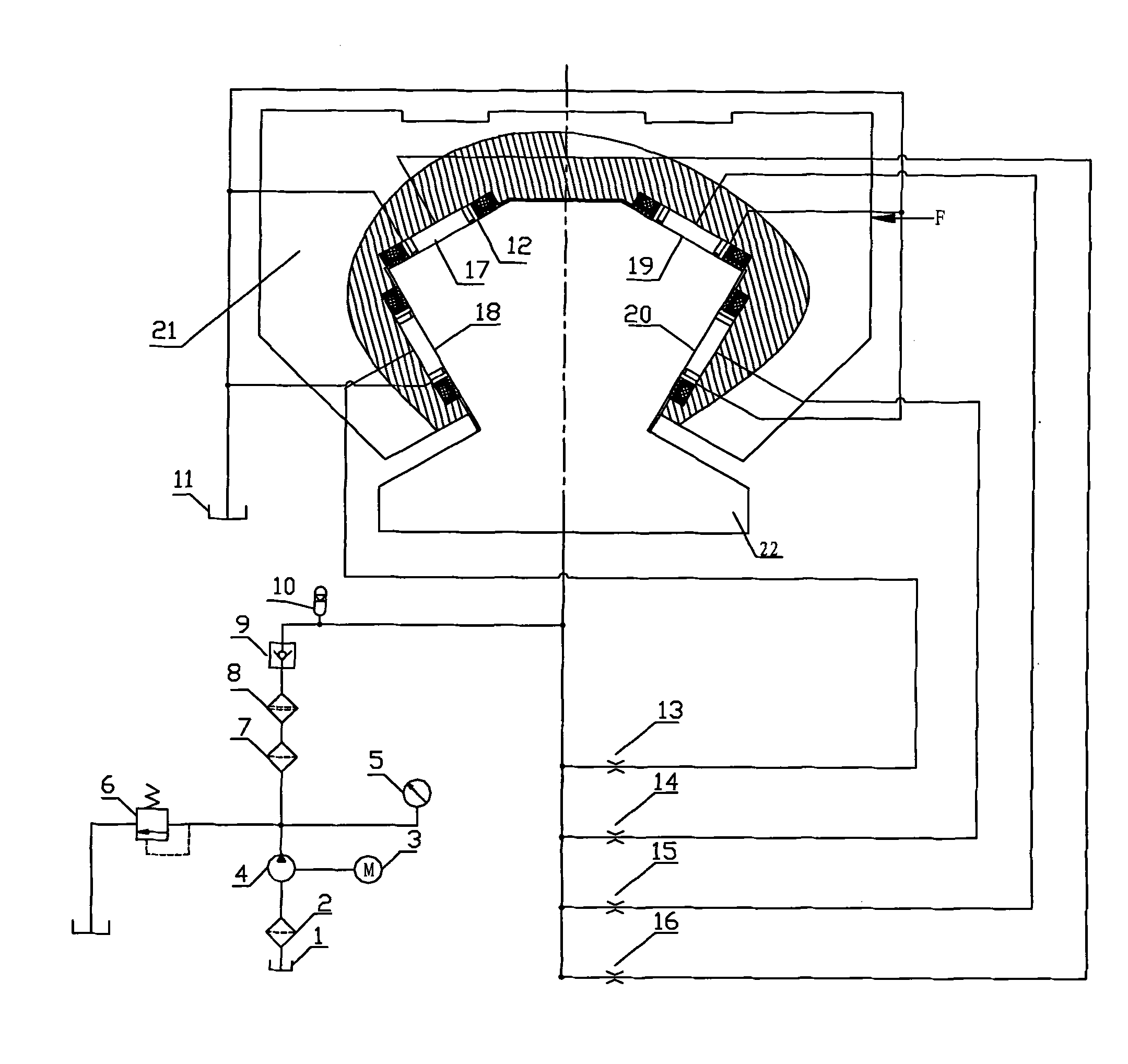

[0023] Such as figure 1 , figure 2 , image 3 As shown, the ultra-precision electro-hydraulic servo control hydrostatic linear guide of the present invention includes a bed 25 and a slide seat 23 for placing a workpiece 24. The bottom surface of the slide seat 23 is fixedly provided with a slide block 21. A groove 26 with an opening downward is formed in the slider 21; and a groove 26 that can be embedded into the slider 21 is fixedly provided on the bed 25 corresponding to the groove 26 of the slider 21 The inner guide rail 22; the inner peripheral wall of the groove 26 of the slider 21 has a plurality of pressure oil chambers for lubrication and load bearing after being co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com