An adaptive multi-inertia channel hydraulic mount and its adaptive method

A hydraulic mount and inertial channel technology, applied in the direction of spring/shock absorber, shock absorber, shock absorber-spring combination, etc., can solve the problems of low lag angle peak frequency, complex hydraulic mount structure, and high cost , to achieve the effect of increasing the damping coefficient, improving the vibration isolation effect and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

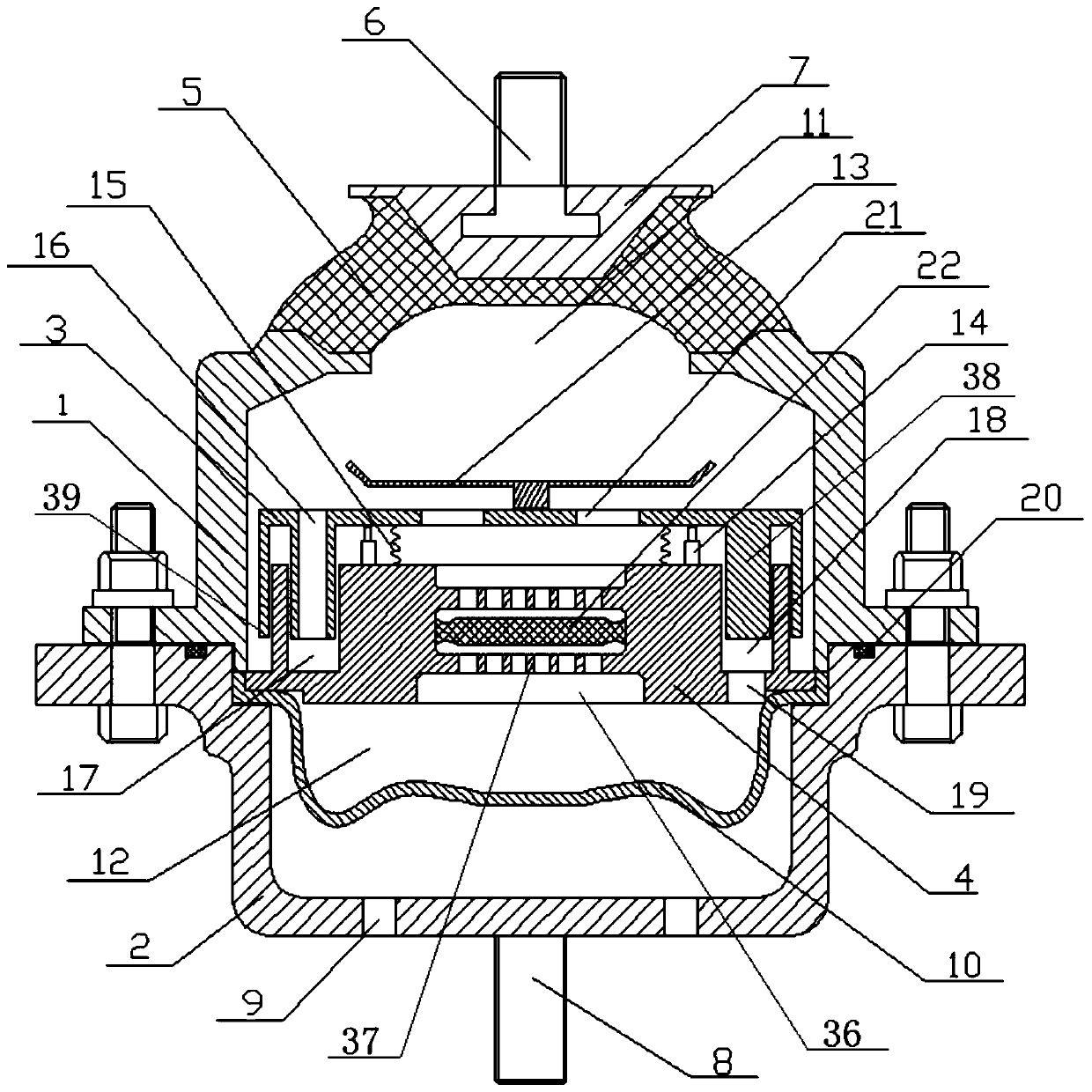

[0048] see Figure 1-3 , The adaptive multi-inertia channel hydraulic mount in this embodiment includes an upper cover assembly, a lower cover assembly, a vibration isolation mechanism, a leather cup 10 and a sealing ring 20 .

[0049] The upper cover assembly includes upper cover 1, rubber main spring 5, upper bolt 6, and reinforcing block 7. Wherein, the top end of upper bolt 6 is installed on the engine, and the reinforcing block 7 is installed at the bottom of upper bolt 6 . Rubber main spring 5 is installed on the bottom of reinforcing block 7, and loam cake 1 is installed on the bottom of rubber main spring 5. Among them, the rubber main spring 5, the upper bolt 6, and the reinforcing block 7 can be fixed by a vulcanization process. Through the above process, the installation among the rubber main spring 5, the upper bolt 6 and the reinforcing block 7 can be made more stable, thereby ensuring the long-term use of the hydraulic mount and improving the safety of the hydr...

Embodiment 2

[0063] see Figure 9 , this embodiment is similar to Embodiment 1 and the only difference is that the up and down movement of the mobile frame 3 in this embodiment is controlled by the first drive unit 13a and the second drive unit 13b, and the booster plate 13 and the guide structure are removed. 14 and spring 15. The bottom ends of the first driving unit 13 a and the second driving unit 13 b are installed on the partition 4 , and their other ends are installed on the side of the moving frame 3 facing the partition 4 . The first driving unit 13a and the second driving unit 13b can be driven by a motor or a hydraulic cylinder. In idling conditions, starting conditions, rapid acceleration conditions, or impact conditions such as passing through uneven roads, the first drive unit 13a and the second drive unit 13b control the size and implementation of the inertial channel cross-sectional area that the moving frame 3 moves to. Same as Example 1. Under high-frequency vibration,...

Embodiment 3

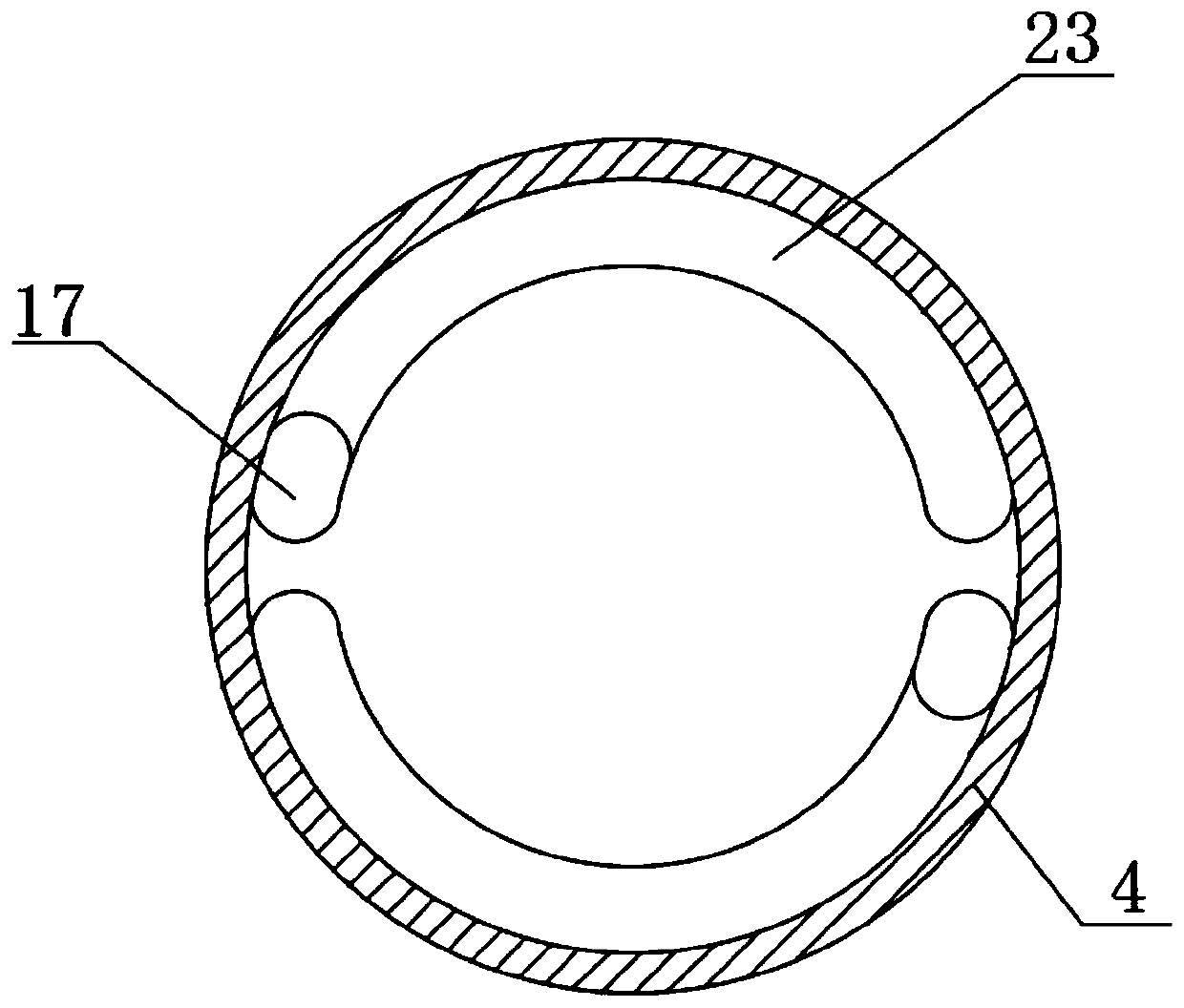

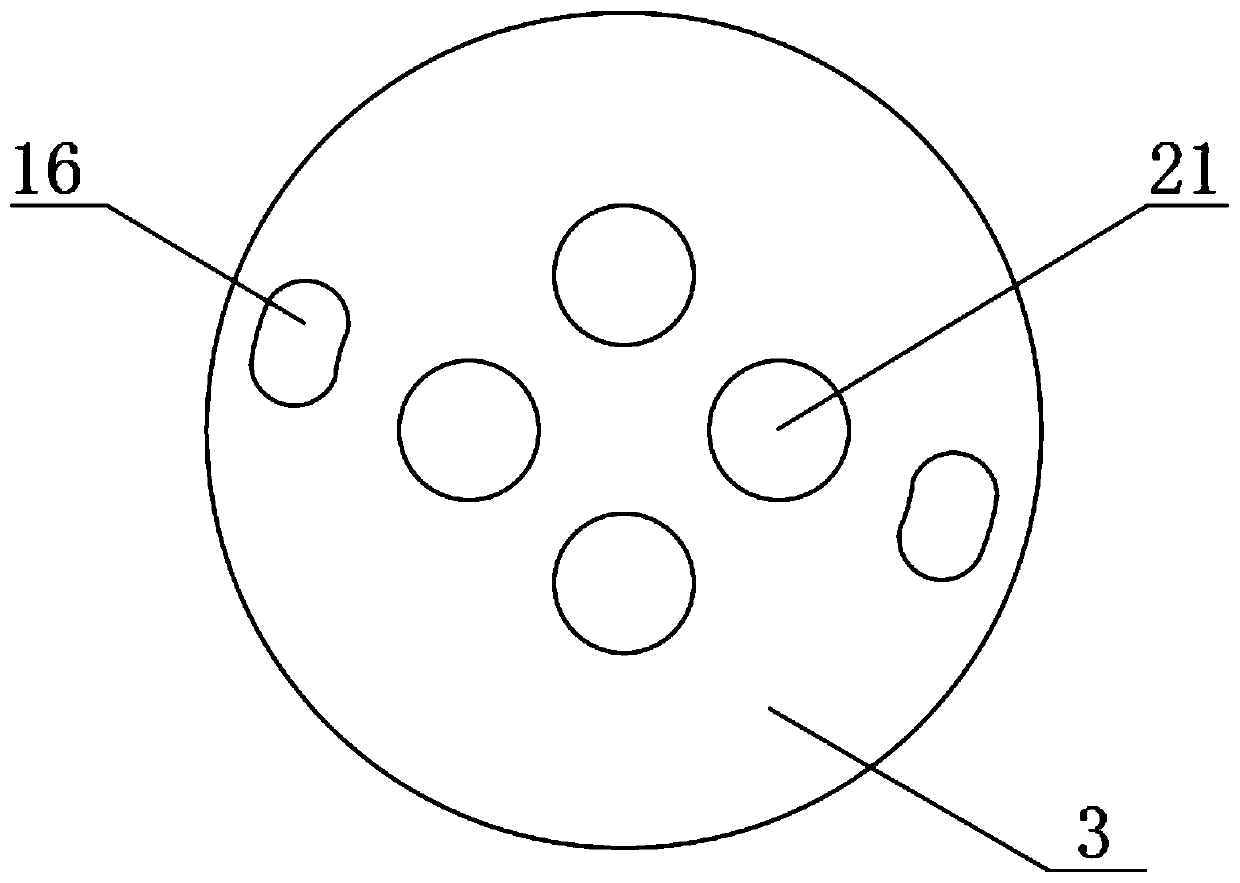

[0065] see Figure 10 with Figure 11 In this embodiment, three arc-shaped runners 23 corresponding to a central angle of 110 degrees are used, and the lengths of the three runners are not limited to the same length, and different lengths can also be used. The three flow channels 23, the three pipes 16, the three first blind holes 17, and the three second blind holes 18 correspond one by one to form three inertial passages. These three inertial passages can make the liquid circulation of the hydraulic device more rapid and the structure more stable. At the same time, the total cross-sectional area of the inertial passages is increased, thereby further increasing the damping coefficient of the liquid and further improving the vibration absorption capacity of the hydraulic mount. , thereby increasing the vibration-absorbing effect.

[0066]In summary, the present invention adjusts the cross-sectional area of the inertial channel by moving the moving frame 3 up and down, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com