Automatic tableware classifying and conveying machine

An automatic sorting and conveyor technology, which is applied in the direction of conveyors, conveyor objects, conveyor control devices, etc., can solve problems such as wasting electricity and affecting the service life of equipment, and achieve the effect of reducing labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] What needs to be explained here is that the location words left, right, up, down, first, and last are all based on figure 1 The views shown are defined by reference, and it should be understood that the use of said localizers should not limit the scope of protection claimed in this application.

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

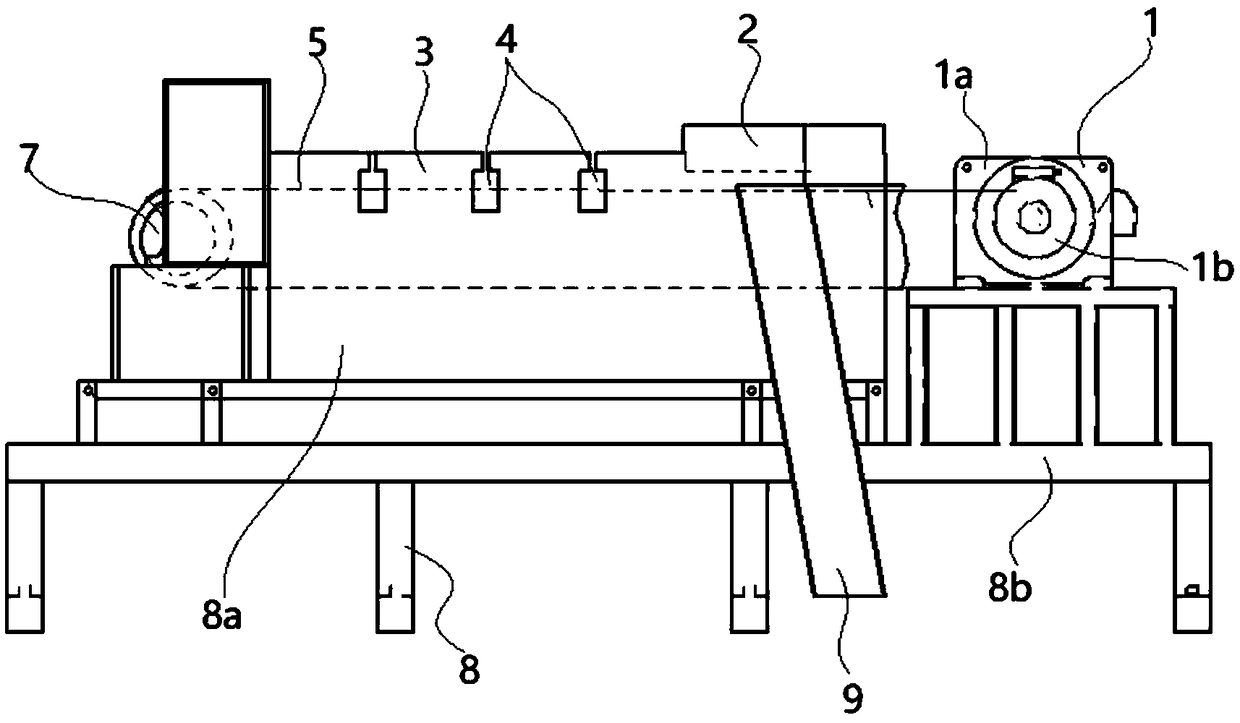

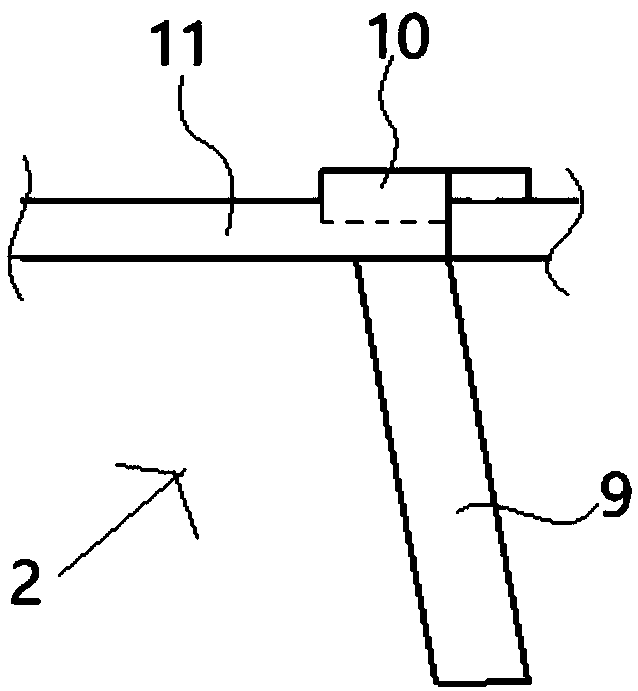

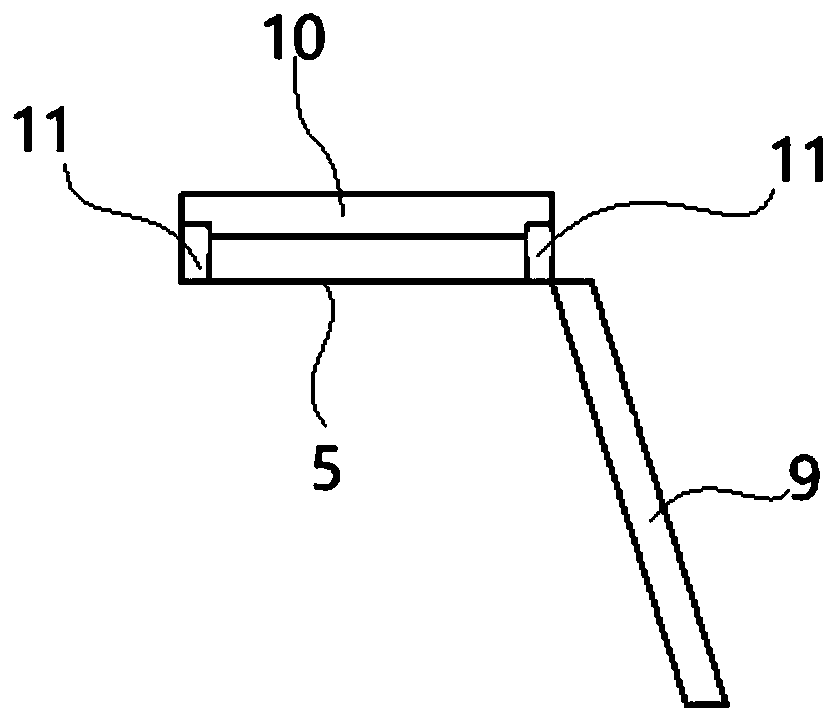

[0020] like Figure 1 to Figure 4 Shown, a kind of tableware automatic sorting conveyer, it comprises photoelectric induction device 6, automatic sorting device 2 and frame 8, is equipped with reversing roller 7 on the center frame 8a of frame 8 left ends, on frame 8 right ends The driving device frame 8b is equipped with a driving device 1, and the driving device 1 includes a geared motor 1a and a driving drum 1b, and the power output shaft of the geared motor 1a is connected to the driving drum 1b through a coupling; 7. The conveyor belt 5 is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com